Pick Your Polymer Properties: Tool Predicts How to Achieve Them with Biomass

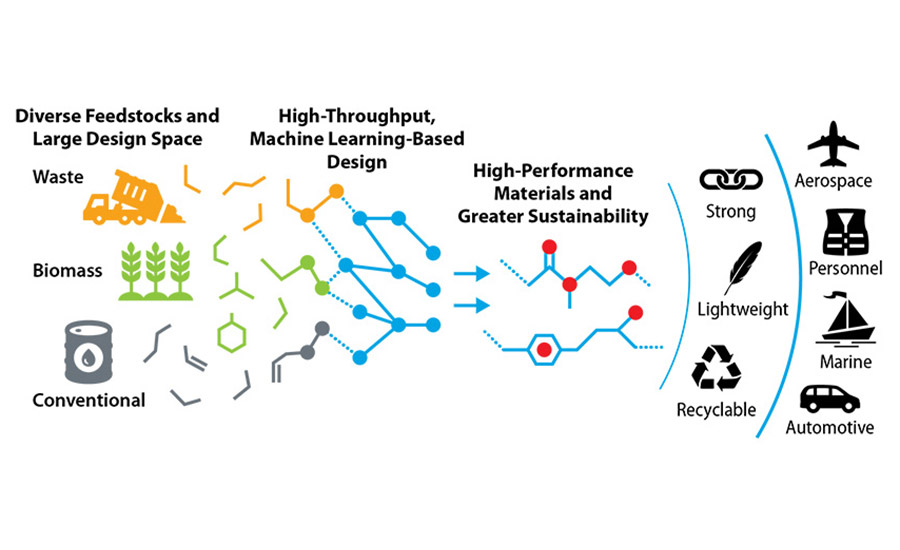

Artificial intelligence speeds the discovery of more sustainable, higher-performing polymers with the help of a new tool from the National Renewable Energy Laboratory.

NanoStockk/ iStock / Getty Images Plus via Getty Images

Great chemists have discovered ways to combine carbon, hydrogen, oxygen, and nitrogen into all manners of plastics: leak-proof food packaging, heat-resistant car parts, durable personal protective equipment — the list is long. The real challenge for a material scientist in the 21st century is finding the perfect recipe for making polymers more sustainable and higher performing at the same time — especially if you only have petrochemicals on hand.

"Petroleum largely comprises hydrocarbons — essentially arrangements of carbon and hydrogen chemically linked together that have some pretty remarkable and advantageous properties," said National Renewable Energy Laboratory (NREL) scientist Brandon Knott. "But hydrocarbons lack heteroatoms like oxygen and nitrogen, and it can require significant energy to add them in when manufacturing polymers needing broader functionality than what hydrocarbons provide."

A good solution, Knott explained, is adding oxygen- and nitrogen-rich biomass and waste to the ingredient list. Corn stalks, algae, and even garbage contain extra chemical linkages that often afford chemists greater flexibility for achieving specific properties. The challenge is finding that perfect recipe for both sustainability and unmatched performance.

An NREL machine learning tool, PolyID: Polymer Inverse Design™, makes it easier to strike the balance. Using artificial intelligence, the tool can predict material properties based on molecular structure. That allows it to screen millions of possible polymer designs to create a short list of candidates for a given application. Created with support from the U.S. Department of Energy Bioenergy Technologies Office, the tool is discussed in depth in an article published in Macromolecules, "PolyID: Artificial Intelligence for Discovering Performance-Advantaged and Sustainable Polymers."

Smart Algorithm

The algorithm behind PolyID is a state-of-the-art advancement to a foundational approach known as "group-contribution theory." The tool builds associations between arrangements of oxygen, hydrogen, carbon, and other elements and material properties to predict attributes like elasticity, heat tolerance, and sealant performance. With a growing library of connections between the molecular structures of polymers and their known properties, it "learns" to predict how new polymers might be designed to achieve specific physical characteristics.

"If you do that with a few thousand polymers to train the algorithm, you start to get really accurate predictions for structures that haven't been seen before by the algorithm and maybe haven't been made before," explained Nolan Wilson, the lead author on the paper.

With thousands of polymers in its reference library, the tool enables scientists to work backward when searching for new polymer designs. They can identify desired properties first and select potential polymer designs.

Case Study

For example, NREL scientists used PolyID to rapidly screen more than 15,000 plant-based polymers in search of biodegradable alternatives to today's food packaging films. Primarily made from high-density polyethylene, packaging films are often designed to withstand high temperatures and create a strong vapor seal to keep the food fresh.

NREL's team prioritized those properties in PolyID, while adding other desirable attributes, including biodegradability and a lower greenhouse gas footprint. The tool generated a short list of seven polymer designs that could be made from biomass. After further testing in the lab, the team confirmed the tool's predictions. Not only would all seven polymers withstand high temperatures, but they could also do so while lowering net greenhouse gas emissions and keeping food fresh for longer periods of time.

Tailoring Polymers to Industry Needs

With millions of unique materials possible from biomass, waste, and conventional feedstocks, prioritizing sustainability in the design of new polymers has been challenging — even for the brightest chemists. That comes as consumers increasingly demand more out of the products they interact with. Many companies are responding by innovating their products to reduce waste, promote recycling, and lower their carbon footprint. But it can be a tricky balancing act to hit those targets without sacrificing product performance.

Where PolyID shines most, according to Wilson, is its ability to position performance alongside a multitude of other sustainability considerations. "Some of these might serve as direct replacements for comparable petroleum polymers," he explained. "But, in many cases, they are even better in terms of performance and sustainability."

That way food packaging can do more than improve shelf life. The coatings on a pair of skis will not only help ward off cold and snow. The thermoplastics shell in a bike helmet might protect more than your brain. They can do that while supporting a healthy environment, too.

This article was published with permission from the National Renewable Energy Laboratory, a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy. Learn more at www.nrel.gov. For additional information about PolyID, access the tool online.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!