Henkel Announces New Sealant Range for Metal Packaging

The one-component sealant system Darex COV 73 is suitable for nozzle application, offering stable viscosity, high resistance to solvents, ketones and oils, and thermal stability.

Henkel Adhesive Technologies announced that the company is introducing a new generation of its Darex COV sealants with formulations that do not contain phthalate-based plasticizers. These formulations ensure the reliable sealing of metal packaging with improved health and environmental credentials. With this step, Henkel reports that the company is setting standards in the early elimination of harmful ingredients in industrial adhesives and sealants.

The phthalate-free PVC-based compounds will gradually replace existing products and provide users with a future-proof solution that complies with current and future regulations, at the same time offering processing and application advantages. The transition is being driven by increasingly stringent legal requirements — including the European REACH regulation — and growing demands for more sustainable packaging solutions along the entire supply chain.

As potential endocrine disruptors, phthalates have been the focus of scientific and regulatory attention for years. Certain types such as DEHP, DBP, and BBP have already been classified as toxic to reproduction and are banned in various applications, including toys and cosmetics. The European Commission has also listed several similar substances in the SVHC (substances of very high concern) category. With this in mind, Henkel took the early decision to switch to phthalate-free (NI) formulations.

“Phthalates are considered endocrine disruptors — substances that disrupt the hormone system — and therefore have long-term health and environmental consequences,” said Laura Baussà, market strategy manager at Henkel. “With the new Darex COV series, we are offering our customers safe alternatives to protect employees and end users without compromising on performance.”

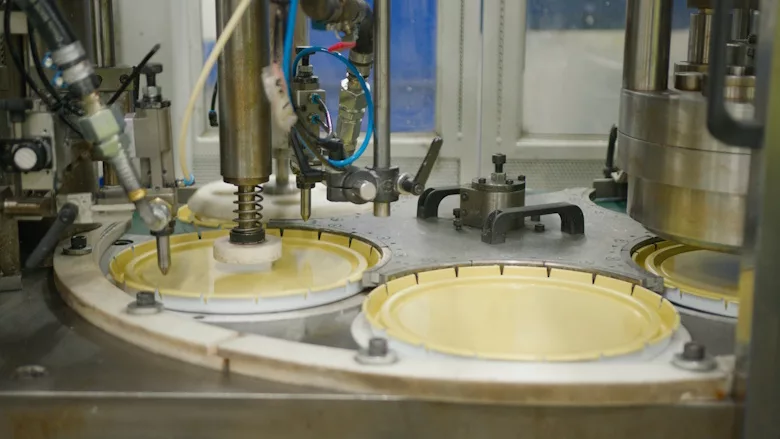

A key focus of development was the formulation of a one-component sealant system that is suitable for nozzle application, offering stable viscosity, thermal stability, and high resistance to solvents, ketones and oils. Darex COV 73 not only does not contain phthalates, but it also avoids the use of ingredients that are classified as carcinogenic, mutagenic or toxic to reproduction (CMR). According to Henkel, the phthalate-free formulation makes it possible to reduce the curing temperature, thus cutting energy consumption and shrinking the application’s carbon footprint.

Darex COV 73 was successfully developed to market maturity in a pilot project with Emballator. The Swedish manufacturer of metal packaging switched several of its facilities to the new phthalate-free formulation in 2024. In collaboration with Henkel, the company is pursuing a clear sustainability strategy and is proactively addressing regulatory developments such as the REACH regulation by adopting technical solutions at an early stage. Applying Darex COV 73 under real production conditions provided clear evidence for both the smooth application process and effective sealing performance.

The new Darex COV range is being rolled out gradually. In doing so, Henkel is actively supporting its customers in the transition to phthalate-free sealants.

Darex® is a registered trademark of Henkel and/or its affiliates in the United States, Germany, and elsewhere.

Learn more about Henkel at www.henkel.com.

Additional information about the latest products in the adhesives and sealants industry is available on ASI’s New Products page.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!