HOENLE: Compact LED Heads

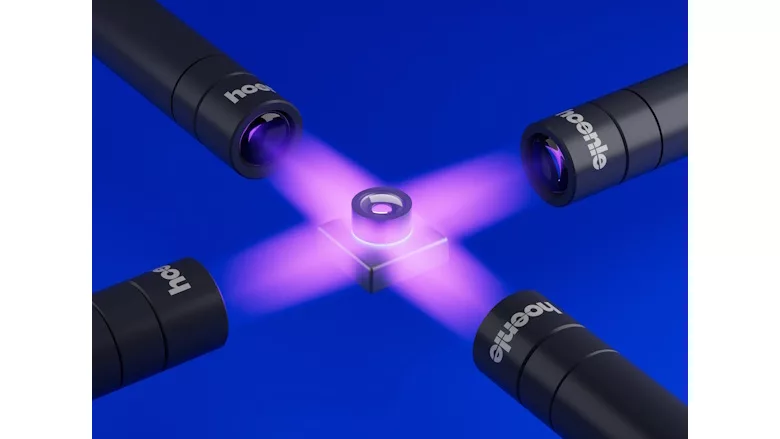

The compact LED UV heads of the bluepoint LED eco are particularly suitable for curing adhesives in active alignment.

UV technology manufacturer Hoenle is introducing a new generation of compact LED heads for its bluepoint LED eco UV curing system. The redesigned heads offer enhanced performance and reduced dimensions, and they can be easily connected to existing bluepoint LED eco devices.

Now even more compact, the upgraded LED heads of the bluepoint LED eco have a diameter of just 12 mm and an overall length of only approximately 55 mm, depending on the optic used. They are ideally suited for extremely tight installation spaces without compromising thermal performance. The compact new LED heads can not only be connected to existing bluepoint LED eco devices but also serve as a drop-in solution for other common curing systems with the same dimensions.

Delivering intensities of up to 20,000 mW/cm², the new LED heads are available in wavelengths of 365, 385, and 405 nm. They can also be equipped with a 90° deflection head, enabling effective irradiation in hard‑to‑reach areas or confined installation environments.

A range of optical lenses is available for the new LED spot heads, covering irradiation diameters of approximately 3, 7, 10, or 20 mm. This allows simple and precise adaptation to specific application requirements. A 10x2 mm optic has recently been added to the portfolio. This optic delivers maximum intensity distributed homogeneously along a line of roughly 10 mm, enabling irradiation of narrow gaps. A typical application is active alignment. Other applications for the bluepoint LED eco include curing UV adhesives and potting materials in a wide variety of manufacturing processes — for example, bonding optical components, needle bonding of disposable syringes, producing glucose sensors, or fixing and encapsulating electronic components.

In addition, the bluepoint LED eco now offers enhanced machine‑safety functionality. The system can be connected to production equipment via an integrated interface and includes a signal input that ensures the LEDs are reliably switched off in accordance with current safety standards. This is a critical safety feature, particularly for fully automated production lines, and provides reliable protection for machine operators.

For additional information, visit hoenle.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!