Liquid Resin Reduces Emissions in Flooring Adhesives

There has been a lot of interest lately in dispersion adhesives for textile and other floor coverings. The functional components of a formulation for such an application are essentially the corresponding polymer dispersion in combination with a tackifier system.

In the past, high concentrations of rosins dissolved in low-boiling solvents or solvent mixtures have mainly been used as tackifiers. For reasons of occupational safety, it has become important to replace, in a first step, the low-boiling solvent either partially or even completely. The functions of the solvent (mix) were as follows:

- To bring the natural resin, which has as softening point of around 70?C, into a form that enables it to be readily worked into the polymer dispersion;

- To let the polymer soak so that the resin can diffuse easily into the polymer particles;

- To act as temporary plasticizer.

As a consequence of the reduction or substitution of low-boiling solvents, formulations based on so-called high-boiling or plasticizer substances have been developed to act as a medium for transporting the tackifier resin into the polymer particles and to adjust the workability of the rosin. This development has led to a clear improvement in the quality of the workplace environment and occupational health.

The Familiar Problem of Odor

In terms of their adhesive properties, these formulations correspond to the earlier dispersion adhesives that contained solvents. However, they concealed one problem that only became apparent with the passage of time, i.e., the familiar problem of odor. After processing this new generation of flooring adhesives, the number of odor complaints to adhesive manufacturers built up, especially in the German market. The plasticizers were suspected of being the potential cause.Investigations showed that despite their high boiling point of more than 200?C, the plasticizers are released relatively quickly into the ambient atmosphere. Since the compounds being used here also have, according to the latest tests, a potential health risk, which is difficult to assess, the adhesives industry was very interested in seeking alternative products.

Adhesives manufacturers have given notice of their long-term aim of finding a formulation that is free of solvent and plasticizer.

After intensive cooperation with BASF in Ludwigshafen, Germany -- a market leader in the field of polymer dispersions for flooring adhesives -- a supply profile was drawn up for a liquid resin for the specified area of application, and an appropriate liquid resin was successfully introduced for BASF's polymer dispersion Acronal A 380.

The basic requirements for a liquid resin were -- besides the necessary compatibility with gum rosin and the polymer used -- low product viscosity along with a low monomer content and a low level of odor. However, adhesive properties should be achieved that are at least comparable with standard adhesives manufactured so far.

Working Together

In cooperation with BASF, RUTGERS VFT AG has succeeded in offering to the market a tailor-made special liquid resin called Novares LS 500, which meets the requirements of EMICODE EC1 classification (see sidebar on pg. 30).The tackifying effect of the liquid resin arises directly from the interaction of the polymer and the resins used in the formulation. In contrast to conventionally applied plasticizer or high-boiling compounds, Novares LS 500 appears as a solubilizer, used in combination with the well-tried gum rosin.

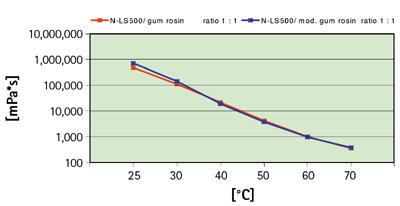

This resin combination is produced by homogenizing the aforementioned resins at an elevated temperature -- around 100?C. It remains liquid but viscous at ambient temperature and does not display any tendency to crystallize. The necessary processing viscosity can be adjusted by raising the temperature (see figure on page 30).

By using Novares LS 500 in combination with gum rosin in the resin blend and additional dosage of a soft resin according to the adhesive formulation, a remarkable improvement in at least three adhesive properties can be realized:

- bond development,

- peel strength and

- dry tack.

Conclusions

Synthetic hydrocarbon resins are now a viable option in the EC1 high-quality sector. This is a major step forward since the volumes of renewable raw materials -- like natural resins -- are definitely limited.Furthermore, the possibility of producing synthetic resins gives the processor -- in contrast to tackifiers based on natural resins -- the advantage of a homogenous composition at all times. It also allows adhesives manufacturers to substitute the high-boiling and plasticizer components previously used.

Controlling Emissions in Flooring Installations

Consumers require reliable information on products for indoor use. Building materials and equipment should not pollute the indoor air with volatile organic compounds (emissions) and odors. Included in these are products for the installation of flooring, e.g., adhesives, primers, smoothing compounds and underlays. Decorators, consumers and craftsmen saw a need to evaluate and select floor-covering materials.Major adhesive manufacturers therefore have founded the German-based Association for the Control of Emissions in Products for Flooring Installation (GEV). They have developed the product-classification system EMICODE, a simple and reliable guideline classifying the emission behavior of such products with a view to consumer and environmental protection.

Flooring-installation materials labeled with EMICODE EC1, "very low emission," offer the greatest possible safety concerning indoor air pollution. The EMICODE system is based on precisely defined chamber-testing procedures and strict classification criteria that have been devised by the technical council of the GEV and with professional support of the environmental institute Milj¿-Chemi, The Carpet Research Institute and the Association for Environmentally Friendly Carpets.

The uniform application of EMICODE by GEV members gives safety to all associated businesses in the selection of flooring-installation materials and establishes consumer confidence in these products.

Products labeled with the EMICODE EC1 stand for modern, solvent-free and very low-emission flooring-installation materials. With respect to indoor air quality, they provide the most ecological method for state-of-the-art flooring installations.

For further information, call the association at +49 (0)211/67931-12, or visit the Web site www.emicode.de.

Additional information on Novares LS 500 liquid resins is available from RUTGERS VFT AG, Business Unit Resins/HKM, Varziner Strasse 49, D-47138 Duisburg, Germany; call +49-203 42 96 02; fax (+49-203) 42 25 51; e-mail info@ruetgers.vft.de; or visit the Web site www.ruetgers.vft.de. Or contact the U.S. agent, Sam Berkowitz, HM Royal, Inc., PO Box 28, Trenton, NJ 08601-0028; call toll-free 800-257-9452 or 609-396-9176; fax 609-396-3185, or e-mail sam_berkowitz@hmroyal.com. Or Circle No. 61.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!