High-Performance Styrenic Block Copolymers Featuring a Novel Hybrid Midblock

Two families of non-hydrogenated styrenic block copolymers (SBC) have been widely used in a variety of hot-melt adhesive applications: styrene-isoprene-styrene block copolymers (SIS) and styrene-butadiene-styrene block copolymers (SBS). Both have unique physical properties and are used in large volumes in their respective application fields. Blending of SIS and SBS into a single formulation can also make economically attractive packaging tape and disposable nonwoven adhesives; improve the hot-melt stability of adhesives; or improve label converting (matrix stripping without adhesive threads). The downside to blending SIS/SBS is that it requires more complex formulating and may afford less than optimal properties when compared to analogous SIS-based formulations.1

KRATON Polymers has recently developed a new family of styrenic block copolymers that feature a hybrid elastomer composition that combines a controlled distribution of isoprene and butadiene monomer units into the mid-block: styrene-isoprene/butadiene-styrene (SIBS). This new concept has the potential to expand the application field of styrenic block copolymers in a variety of hot-melt adhesives applications such as pressure-sensitive tapes, labels and nonwoven construction. This article will provide examples of starting-point formulations, and will present and discuss resultant properties.

Five key objectives have been met with this new development:

1. By combing isoprene/butadiene monomer units, manufacturing requires less isoprene monomer, a commodity chemical that has been in short global supply since early 2004.

2. For properly designed molecules, adhesive performance is equivalent to SIS.

3. The hybrid concept affords a dual degradation mechanism of chain scission and crosslinking, resulting in hot-melt formulations with improved viscosity stability.

4. The hybrid rubber phase has a lower glass-transition temperature (Tg) and can provide pressure-sensitive tack at lower temperatures.

5. The SIBS concept brings to the market a new opportunity for a conventional three-component system (polymer, single resin, plasticizer) suitable for existing mixing/coating equipment.

Physical Characteristics of SIBS

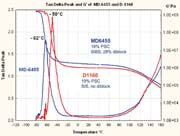

The hybrid elastomer composition of this SBC has a significant influence on the intrinsic physical and chemical properties of the polymer. Properties of particular importance for adhesive applications are the rubber glass-transition temperature, the elastic modulus G' and the solubility parameter.Dynamic mechanical analysis (DMA) is an excellent tool for discerning the differences between SIBS (19% polystyrene content) and SIS (equivalent polystyrene content). The DMA spectrum is shown in Figure 2. Some major differences worth noting include the following.

- The elastic modulus G' of SIBS is higher than that of an SIS, but low enough for pressure-sensitive tack. The elastic modulus G' is inversely proportional to the molecular weight between entanglements Me (Me of polybutadiene is smaller than that of polyisoprene).

- The dynamic mechanical response of the glass/rubber transition phase shows two effects: lower Tg and a smaller transition.

- The Tan Delta curve of SIBS shows a mid-block Tan Delta Peak value at about -62°C, about 12° lower than that of the isoprene mid-block of an SIS, whose value is at around -50°C. The lower Tg is an attractive new feature for the development of low-temperature adhesives.

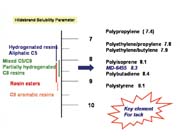

Hildebrand solubility factors are a useful starting point for understanding the formulation compatibility of resins and polymers.2-3 The solubility parameters of polyisoprene and polybutadiene are different: δ = 8.1 and δ = 8.4 (cal/cm3)½, respectively. As both polyisoprene and polybutadiene are present in the mid-block, the resulting solubility parameter has an intermediate value that gives it a slightly more aromatic character. This feature will have an important influence on the tackifying resin selection, particularly for pressure-sensitive tack. The resin compatibility map is shown in Figure 3.

Pressure-Sensitive Adhesive Formulations

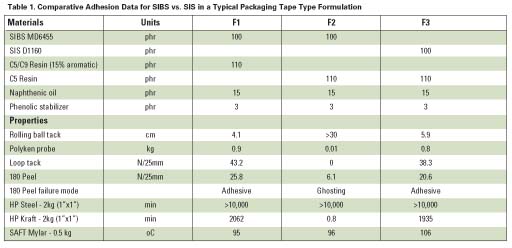

In a specific example, MD6455 (19% polystyrene content and diblock content of 28%) can be formulated to achieve excellent tack properties, provided the resin has an aromatic content (measured by proton NMR) of 15-30%. Excessive aromatic content in the C5/C9 resin can have detrimental affects on shear properties by plasticizing the polystyrene domains. Table 1 shows comparative adhesive properties of an SIS vs. SIBS using a C5/C9 resin with an aromatic proton content of about 15% and softening point of 91°C.

The data in Table 1 reveals how resin choice is critical for SIBS in pressure-sensitive applications. When good resin compatibility is achieved, PSA properties are very comparable to SIS. Note that the higher SAFT value for the SIS is due to the fact that this polymer is fully sequential (no diblock).

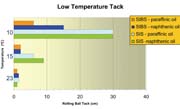

The lower Tg of the hybrid mid-block can be exploited to make PSA formulations with improved lower temperature tack compared to SIS. In addition, we have found that the SIBS formulations perform slightly differently with respect to the plasticizing oil choice. In the following examples, SIBS (MD6455) was formulated with 100 phr polymer, 110 phr resin (15% aromatic), 10 phr oil (naphthenic or paraffinic) and 3 phr phenolic stabilizer. The rolling ball tack was measured at 22°C, 15°C and 10°C, and this data is summarized in Figure 4.

For time-dependant tack, SIBS imparts better low-temperature performance as would be expected due to the lower Tg of the mid-block. It should be noted that, for the SIBS formulations, RBT values rise quickly below about 5°C.

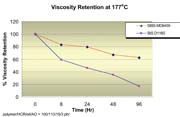

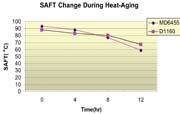

Figure 5 shows the heat-aging behavior of SIBS in a tape formulation. Compared to the analogous SIS formulation, better viscosity retention is observed. Most importantly for the end user, however, the viscosity does not increase as it does for SBS polymers. Moreover, GPC analyses of heat-aged samples show a pattern of degradation that is more similar to SIS than to SBS.

Two important performance requirements for pressure-sensitive adhesive labels are die-cutting behavior and adhesion to curved surfaces. In the manufacture of label stock, the PSA can limit the ease and cost of converting. In general, block polymers with high diblock content are preferred as a way to reduce the cohesive strength of the formulation.

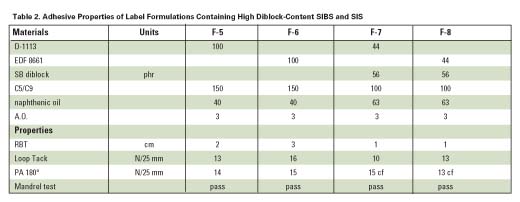

EDF 8661, a high diblock SIBS, was developed for label applications. It is a linear molecule with low polystyrene content and high diblock content. In the following examples, it was compared to Kraton D1113, a high-diblock-content SIS.

F5 and F6 are typical formulations for labels. F7 and F8 contain a styrene-butadiene (SB) diblock copolymer, as it is quite common to blend this ingredient in label formulations to improve the convertibility properties.

The converting and die-cutting behavior of EDF 8661-based hot-melt formulations was tested by transfer coating from a siliconized liner onto 70 g/m2 paper. The adhesive coating weight was 20 g/m2. The paper facestock was then converted into labels using Focus™ converting equipment (rotary die). The converting and die cutting was done at Fachhochschule München, Verfahrenstechnik Papier-Kunststoff Studiegang.

The label trials consisted of cutting labels using easy and difficult shapes. Different blades were used, differing in sharpness. A blade angle of 60° represents a relatively sharp blade (cuts well but is fragile); a blade angle of 110° is not sharp at all - the paper is more pushed away than cut. This last blade is more forceful, therefore it is often preferred by the industry.

In this study, the die-cutting behavior of EDF 8861 alone, or with SB diblock, was excellent and comparable to D-1113.

Nonwoven Adhesives Applications

KRATON Polymers has successfully developed high-polystyrene-content SIS and SBS block copolymers for hygiene adhesives in the past.4-5 Those polymers are used primarily for two distinct applications in diapers: for construction adhesives to laminate the nonwoven backsheet to the polyethylene topsheet, and for elastic-attachment adhesives to adhere elastic threads to polyethylene and nonwovens films to form an elastic waistband or legband.The requirements for such applications are stringent: very low HM viscosity at the processing and application temperatures for fast melting, high-speed delivery, and effective application. In addition, the formulation should possess sufficient high-temperature-shear strength to maintain the bond without loss of adhesion at ambient and up to the upper use temperature (38°C). In general, SBCs are useful since they have good adhesion to non-polar substrates like polyethylene sheet, polypropylene nonwovens and elastic strands.

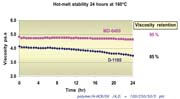

The new SIBS block copolymer MD-6460 provides formulators with such functionalities, with the additional benefits similar to those of MD-6455. More specifically, the high-polystyrene SIBS shows improved hot-melt stability vs. the conventional SIS, and lower hot-melt viscosity with hydrogenated hydrocarbon resins.

Physical Characteristics of High-Polystyrene SIBS

MD6460 has been designed with a multi-arm structure and contains 30% polystyrene. It has a low molecular weight to achieve low hot-melt viscosity, and an optimized isoprene/butadiene structure. An analogous SIS grade would be Kraton D1124 that has the same styrene content, branched structure and diblock content (30%).

Adhesive and Rheological Performance

The construction adhesive is usually sprayed from a nozzle in a spiral pattern at 130-160°C directly onto the polyethylene film, or sprayed as fine fibers. The bond is formed almost immediately when the nonwoven web is nipped to the polyethylene.

Elastic-attachment adhesives are also sprayed in a spiral pattern. Multiple strands of elastic threads are elongated, usually at 300%, and coated with the adhesive at about 150°C. This composite will then contract to form an elastic band. The sprayability of the SIBS formulation has been found to be excellent and similar to an SIS formulation.

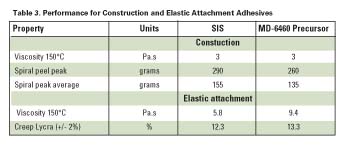

The MD-6460 precursor has been tested in two different formulations: a construction adhesive and an elastic-attachment adhesive. Both formulations have been sprayed and tested in standard operating conditions.6

The construction adhesive formulation is: polymer/hydrogenated hydrocarbon resin/white oil/antioxidant = 100/272/125/2.5 phr; and the elastic attachment adhesive formulation is: polymer/hydrogenated hydrocarbon resin/white oil/end block resin /antioxidant = 100/245/36/30/2.5 phr.

Regarding elastic attachment adhesives, after application on the strands, the laminations have been stretched to 95% of full extension and fastened to a rigid piece of cardboard. The ends of the elastic are cut, the laminations are placed in an incubator for four hours at 38°C and, after that, the creep is measured.

The results obtained for the two applications are presented in Table 3 and indicate that SIBS formulations perform similarly to SIS formulations.

Hot-melt stability of a MD-6460 model formulation has been measured for 24 hours at 160°C with a Brookfield Thermocell viscometer. As seen in Figure 8, the MD-6460 formulation stability is superior to that of the SIS formulation, an effect also observed earlier for MD-6455. The SIBS formulation keeps its viscosity retention up to 95%. At the end of the test, the polymer was analyzed by GPC and showed only about 3% degradation.

The thermal stability of SIBS is a unique feature of the new technology compared to SIS.

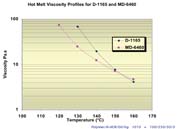

Diaper manufacturers are using thinner gauge polyethylene to manufacture diapers. When the gauge is decreased, the likelihood of a burn-through of these thin films increases. It is therefore beneficial if the hot-melt adhesive could be applied between 130-160°C.

In the model formulation presented in the Figure 9, SIBS polymers show an unexpected effect with hydrogenated hydrocarbon resins, namely a lower hot-melt viscosity at lower temperature than comparable SIS formulation.

This lower hot-melt viscosity might open new opportunities for the formulators as commercial SIBS adhesives could be applied at lower temperature than SIS formulations.

Conclusion

KRATON Polymers has developed a technology platform based on a new hybrid midblock for uses in tapes, labels and nonwovens applications. These SIBS block copolymers have unique attributes that differentiate them from the other styrenic block copolymers, such as the following.- A lower mid-block Tg than SIS

- Improved polymer thermo-stability compared to SIS and SBS

- Different compatibility windows towards tackifying resins and plasticizers

- Excellent compatibility with SIS and SBS

- Comparable adhesive properties to SIS

For more information, contact Donn DuBois, donn.dubois@kraton.com.

References

1. Lutz, Jacobs 2001 PSTC Conference, Orlando, FL. "SIS/SBS Based HMPSA for Opp Packaging Tapes."2. Hildebrand, J.H. The Solubility of Non-Electrolytes. New York: Reinhold, 1936.

3. Handbook of Polymer-Liquid Interaction Parameters, CRC Press, 1990.

4. Chin, Steven S. "New High Styrene Content Isoprene Based Styrenic Block Copolymers." 1991 Hot Melt Symposium, Hilton Head, SC.

5. Southwick, J.G. "High Styrene Block Copolymers in Hot Melts." 1990 Hot Melt Symposium, San Barbara, CA

6. 2004 Evaluation by Adherent Laboratories, www.adherentlabs.com.

SIDEBAR: Experimental

Formulations used for adhesives testing were prepared in glass jars by making 40 wt % solutions of a given formulation in toluene. The solventborne formulations were mixed by rolling the jars for 24 hours. The formulations were coated on 1 mil thickness Mylar film (attached to a glass plate). The Mylar was cleaned with acetone prior to coating. Similar coating procedures were used for other substrates as well.For a 40% solids solution in toluene, the 0.004 fix bird applicator yields a dried-film thickness of about 1.5 mils. The coated samples were then dried for four hours under vacuum at 40°C in an oven that had a nitrogen blanket. After the drying process, the film samples were stored in a controlled temperature (23°C) and humidity room for 12+ hours before any testing was initiated.

Formulations used for viscosity stability (heat aging) were prepared by hot-melt mixing samples in the Baker Perkins sigma blade mixer held at 177°C. A nitrogen sweep of 10 SCFH was used to keep oxygen exposure to a minimum. These formulations were then tested using a Brookfield Thermocell Viscometer.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!