ONLINE EXCLUSIVE: Reducing Fischer-Tropsch Wax Content in Hot-Melt Adhesives

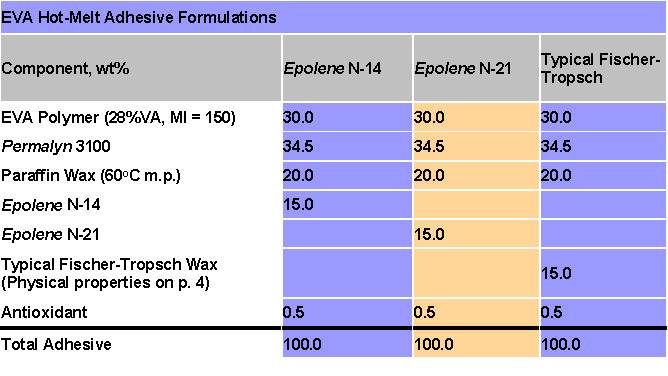

The adhesive formulations presented are intended to be starting-point formulations and may be optimized by adjusting the proportion of components or by adding various performance-enhancing additives used by most adhesives formulators

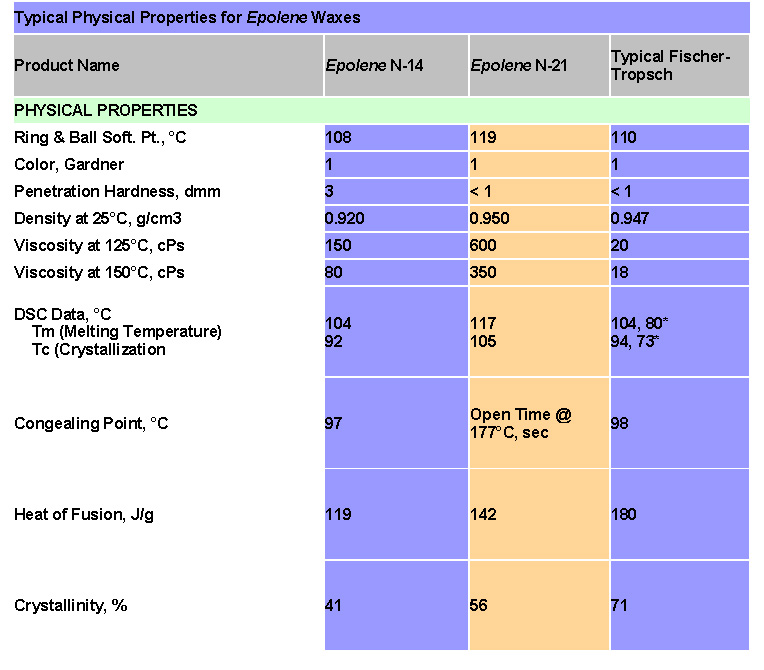

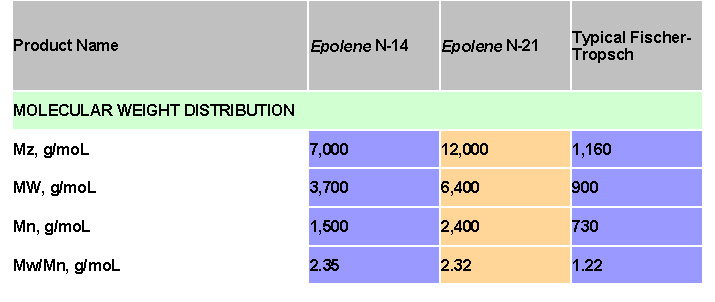

- Epolene N-14 Polyethylene Wax* - A nonemulsifiable medium-density, relatively low molecular weight polyethylene homopolymer. Due to its relatively low viscosity, Epolene N-14 can be used to modify flow properties and set speed in HMAs.

- Epolene N-21 Polyethylene Wax* - A nonemulsifiable, higher density polyethylene wax. Because of its relatively high softening point and relatively low viscosity, Epolene N-21 is used as an additive to adjust set speed in HMAs.

- Permalyn 3100 Synthetic Resin* - A hard, low-color, thermoplastic pentaerythritol (PE) ester of rosin. The use of Permalyn 3100 offers useful properties in HMAs by providing specific adhesion, improved wetting characteristics to various substrates, as well as viscosity control.

Conclusion

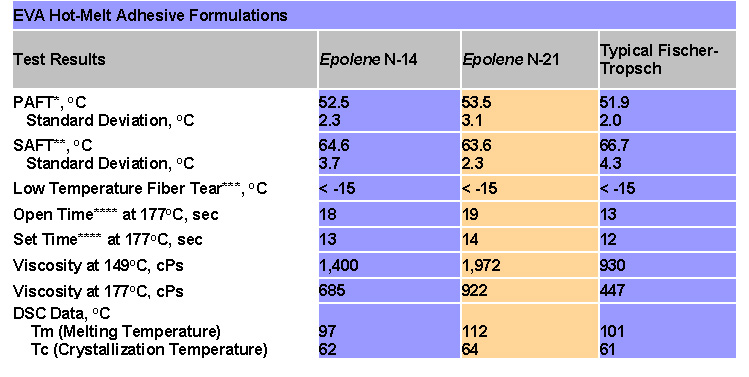

These concepts are intended solely as initial work to evaluate HMAs with properties similar to those of a control formula using 15 wt. % F-T wax. Based on these concepts, it may be possible to reduce F-T wax content.

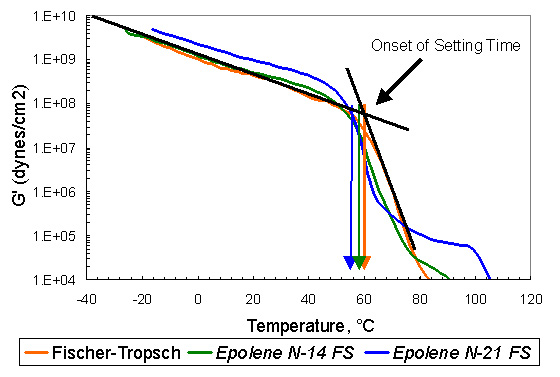

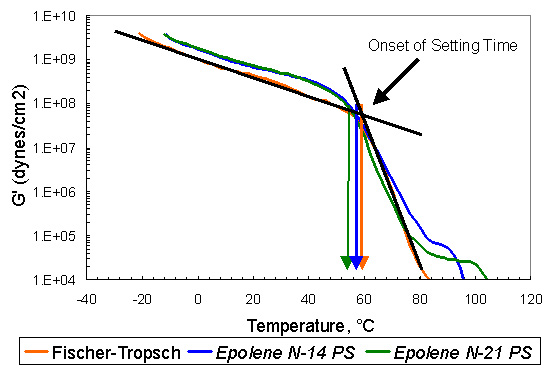

As shown by PAFT, SAFT and low-temperature fiber tear results, full or partial substitution of F-T wax in an adhesive formulation with Epolene waxes provides formulators with similar adhesion, cohesion and set time. In general, the use of Epolene waxes provide higher formulated viscosity and longer open time than F-T waxes.

Based on ring & ball softening point (R&BSP), congealing point and viscosity, Epolene N-14 is the best functional equivalent.

Epolene N-21 is the best functional equivalent based on density, hardness and heat of fusion.

For more information on formulation strategies using tackifiers, phone (800) EASTMAN or visit www.tackifier.com.

*Epolene N-14 Polyethylene Wax, Epolene N-21 Polyethylene Wax and Permalyn 3100 Synthetic Resin are trademarks of Eastman Chemical Co.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!