Stencil Prinitng SMT Adhesives: A Technology Review

Anyone closely involved with the process of surface-mount assembly is familiar with the challenges of materials deposition. This complex process requires highly developed materials and equipment to produce reliable results. In the past, SMT adhesive deposition was accomplished primarily by high-speed automatic dispensing, pin transfer and stencil printing.

Stencil printing, recognized for many years as a viable and cost-effective method of applying adhesives, is now emerging as the chosen deposition method for high-throughput assembly environments. Increasing component counts and faster placement equipment require a method of adhesive deposition that is more rapid than dispensing and more flexible than pin transfer.

While many board manufacturers have already been printing adhesives for SMT applications, much of the technology is not well understood.

For high-volume manufacturing applications such as automotive and consumer electronics where SMT adhesives are required for the assembly process, stencil printing of the adhesives offers the most cost effective method of manufacture. Since print cycle time is short and the board design does not change, the cost of the stencil is absorbed over the life of the product - usually one or two years.

For more information, contact Alden Johnson, Speedline Technologies, e-mail ajohnson@speedlinetech.com ; or visit http://www.speedlinetec.com .

Application Study

Successful SMT Adhesive PrintingA review of a recent Speedline Technologies customer challenge demonstrates the principles that comprise a successful SMT adhesive printing process.

Summary

Materials used:

- Stencil: Aluminum plate, 0.125-inch thick machined and electroless nickel plated

- Squeegee: Rheometric Pump

- Chip Attach Adhesive: Heraeus PD 955 PR

- Printer: Speedline AP Excel

- Optical Microscope: Nikon

- Height Measurement: Cyberoptics, Cyberscan 200

Challenge

Manufacturers have shown a recent interest in printing glue for adhering discrete (as well as active) components to single- and double-sided boards with cinched components. Metal and plastic have been effective in printing glue on PCBs prior to inserting through-hole components. However, there are applications where through-hole cinched components are already inserted into the board before glue is deposited.

This sequence of having the components already inserted requires a stencil that is relieved on the bottom for the cinched leads, and apertures that are in contact with the substrate to allow controlled deposits of the adhesive. Laminated stencils have been tried, but for complex designs that require adhesive dots close to cinched leads, the solid material stencil is required. This method of stencil manufacture consists of matching the relief for the cinched leads on the bottom side and then machining the apertures for glue deposit from the top side.

Print Results

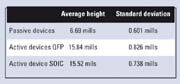

See chart.

Summary

This method of stencil manufacture has produced acceptable results and shows that a stencil machined from a sheet of aluminum and coated with electroless nickel can be used to print chip attach adhesive for assemblies that have cinched leads and dense circuitry.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!