COVER STORY: Packaging for the New Millennium

Cartridges and static mixers revolutionized the market for two-component adhesives and sealants by making them easy and convenient to use. This packaging concept has served the industry well, but the requirement for special dispensing tools makes it unattractive to some market segments.

TAH Industries has developed a new two-component cartridge platform that is significantly different than the cartridges commonly used today. The Universal Cartridge is a two-component cartridge that fits in a standard single-component caulking gun and has a capacity of 250 ml in a 1:1 ratio, and 180 ml in a 2:1 ratio.

The idea driving this concept is the requirement for special tools to dispense two-component adhesives and sealants, a hurdle that some potential users never overcome. The added cost and inconvenience of procuring the tool causes some potential users to shy away from what would otherwise be the best product for their application. Some two-component products are not penetrating their potential markets as deeply as they could because of their need for a special side-by-side dispensing tool. Other markets are not accessible to two-component products in their current side-by-side package, such as the DIY and home-improvement markets.

The TAH Universal Cartridge was created to enable adhesive manufacturers to break through the side-by-side dispenser barrier without sacrificing cartridge capacity and convenience when dispensing and mixing two-component adhesives and sealants. The new cartridge can be re-closed if the application requires only a portion of its contents. The cartridge outlet will accept industry standard static mixers, available in many sizes to meet the specific requirements of an adhesive system.

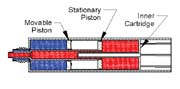

The Universal Cartridge stores one component of the adhesive in front of the other, but both are extruded through the cartridge outlet and into the static mixer simultaneously. The rear piston remains stationary. As the figure on p. 21 shows, when the inner cartridge is pushed forward, the red fluid is extruded through the center tube and out through the cartridge outlet. The front piston is pushed forward as the inner cartridge moves forward, causing the blue fluid to be extruded through the cartridge outlet at the same time.

Other products on the market designed to allow two-component materials to be dispensed with standard caulking guns include the following.

- Barrier and injection style packages. The strength of this packaging lies in its ability to dispense materials in ratios other than the standard 1:1, 2:1, 4:1 and 10:1 configurations. However, the end user is responsible for mixing the product sufficiently either manually or with an electric drill. If the user doesn't mix the contents correctly, performance of the adhesive system will suffer. If the contents are mixed too thoroughly, the adhesive will begin to cure in the cartridge prematurely, and may become unusable before the task is completed. In addition, the entire contents of the package must be used within the working time of the chemistry. Anything not used immediately will cure in the cartridge and be wasted.

- The TAH 50 ml Conversion Kit allows users to dispense adhesive out of a 50 ml cartridge (using a standard caulking gun) by fitting the cartridge in a sleeve adapter. The adapter and plunger are then placed in the caulking gun, allowing the 50 ml cartridge to be used in this standard device. This product is used primarily in the DIY market and by adhesive OEMs for sampling product to customers without having to supply a side-by-side dispenser.

- The 150 ml coaxial cartridge is another product that addresses the special dispenser problem. The cartridge is half as long as a standard 310 ml caulking cartridge. The adapter needed to dispense this cartridge uses half the length available in the caulking gun; therefore, the maximum capacity of this type of cartridge is constrained to 150 ml or 5 oz.

- A two-component sausage pack that fits in a standard gun is available. This product is better suited to adhesive systems that do not require strict ratio control. It is important to note that this cartridge is capable of handling only wide-ratio materials such as 10:1 polyesters.

Filling the Universal Cartridge is also streamlined; all pistons are pre-inserted, and the entire cartridge assembly is leak-tested as part of the manufacturing process.

To determine if the Universal Cartridge is the right package for your product, you must first determine if your target market will place value on the ability to dispense your product without the need for a special dispensing tool. If it will, you must evaluate available cartridge systems based on the following criteria: Can the cartridge system contain your adhesive product reliably? Can the cartridge system hold enough material to serve the needs of your target market? Does your application require accurate volumetric ratio control?

For more information on cartridge systems, contact TAH Industries, phone (800) 257-5238; e-mail

universal@tah.com ; or visit http://www.tah.com/universal .

Anchors Aweigh

One example of a market already benefiting from the Universal's new packaging concept is the adhesive anchoring segment of the construction market. Epoxies are used in this market to hold rebar and threaded rod in holes drilled in concrete.U.S. Anchor, a Pompano Beach, FL-based adhesive anchor manufacturer, has set out to increase its penetration into this market segment. Contractors are finding it advantageous to make use of the caulking guns they already own rather than having to purchase additional special tools when they need greater flexibility or capacity. U.S. Anchor has also found that there is a significant untapped market segment made up of small contractors and homeowners who find the high cost of special dispensers prohibitive.

Steve Shade, vice president of U.S. Anchor Corp., says, "We call the revolutionary cartridge system EZ-Mix because it is just that simple and easy to use. For the first time, a homeowner can purchase our high strength Ultrabond Epoxy in a single cartridge and use it without pumping or hand mixing."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!