Savvy Filtration Techniques Improve Profits for Adhesives Manufacturers

Consequently, filtration of adhesives and sealants may be very simple or very complex. When the end product is extremely expensive, one would not want to lose large amounts of it in the filter element as cleavage.

Filtration of adhesives and sealants can involve a variety of materials that are water-based, solvent-based or 100 percent solids. The latter, such as bone glue flakes, powder or hot melts used in the carpet industry, may require filtration while the adhesive is very hot. This can create special problems in terms of the temperature requirements of the filter elements. The simpler glues may require filters similar to those used for coatings, and, in that sense, the filter may have to handle materials that are very thin and low in viscosity or very heavy and thixotropic.

Adhesive and sealant filtration is highly dependent upon viscosity and rheological properties of the base resin. It is this resin that cures and binds the adhesive or sealant to the substrate to which it is applied. The substrate can vary from a clean metal finish in a spacecraft to an inexpensive plastic.

Proper filtration is key to producing a quality end product, whether that adhesive binds rugs together at the seams or adheres annual stickers to license plates. Also, since adhesives are often two-component systems, both components may require filtration prior to packaging.

The Importance of Quality

As with many industries, one cannot overlook the importance of good filtration techniques for basic liquid raw materials used in adhesives and sealants, including resins, emulsions, liquid additives and even water. One should not assume that the liquids – as received — are pure and clean and free from particulates. Dirt and particulates can make their way into a drum or tank car, often appearing as sediment on the bottom of the container or transportation vessel. If the contaminants get into the finished product, they can be very detrimental to adhesive performance.Adhesives and sealants are film formers. It is not unusual for skins of polymeric material to form in a drum or in a tank either during transportation and shipment or during storage (particularly if placed outside and exposed to ambient conditions with wide temperature swings). If skins get into a batch during the manufacturing of a thin-down (dilution to desired percent solids), expensive filtration may be the only way to remove the material. Removal may be difficult because the particulates are soft, pliable and flexible, and easily clog any kind of filter – even if the filter is back-flushable.

Also, it is not uncommon for a batch to experience “seeding,” flocculation or premature curing. These problems occur for a number of reasons but can often be attributed to inattention to batch-manufacturing instructions. For example, improper addition of minor batch components, such as coalescers or anti-skin agents, can lead to quality problems that can gum up the filtration operation.

In summary, filtration is often asked to be the solution to quality problems that were not addressed during incoming inspection of raw materials, improper storage and temperature exposure of raw materials/ingredients, or errors in the manufacturing and packaging processes.

Selecting the Right Filter

One can understand that the type of filtration used for caulking on a swimming pool is not the same as used on an adhesive to bind an expensive, high-temperature engine part. When a manufacturer wants to produce high-quality product with tight particulate-removal demands, operators will turn to pleated bags or cartridges with high dirt-loading (particulate-loading) capabilities. Of course, clear adhesives – such as those used in safety glass – cannot contain any visual particulate. It is important to match the filter to the quality desired in the end product.Knowing this, one should recognize that filters for certain adhesives and sealants require special materials of construction that involve both the selection of the media (metal, paper, polyester, polypropylene), and the filter housing and supporting hardware. Some applications may dictate the use of corrosion-resistant materials or plastics. (If plastics are used, the units must be able to withstand the pressure requirements of the filtration system.)

With respect to pressure, there is a tendency to simply add more pressure to a filtration system to increase throughput. But this can be a fallacy. Operators should understand that in any filtration operation there is a point, called the Tiller Point, where additional pressure on the filter no longer achieves any additional throughput.

Filtration Basics

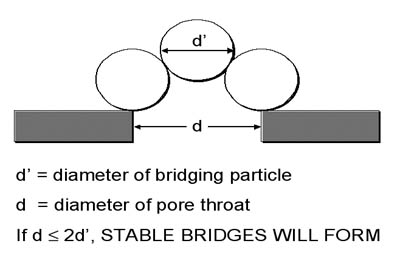

It is common for adhesive and sealant manufacturers to achieve particulate removal using bags or cartridges. Certain types and sizes of particles suspended in the liquid vehicle are allowed to pass through the filter media while the “boulders” are filtered out. Specifically, liquid filtration is the process of separating suspended particles from a liquid by passing the stream through a permeable medium. Dissolved solids generally cannot be removed by filtration without some form of pretreatment. In adhesives and sealants, filter bags and filter cartridges are typically used to remove particles that range in size between 0.5 and 70 microns.Engineers are able to explain why filter media with specific size pores or openings are able to capture particles with smaller diameters than those of the pores. According to classic bridging theory, a stable bridge will form over a pore if two or more particles with diameters at least one half that of the pore diameter contact the opening at the same time. This newly formed bridge (Figure 1) contains even smaller pores that in turn capture smaller particles.

Polymeric materials and the collected particles themselves can sometimes be released from the filter medium and pass downstream. If this happens, the batch quality may be affected. Variations in flow rates and pressure surges are common causes of particle release. Even under ideal flow conditions, filters can release particles if their medium structure is subject to pore enlargement. This is a typical occurrence in string-wound filters and low-density felt bags whose pore sizes change in response to increased pressure.

The best filters are designed with filter medium that have fixed pore structures that are not affected by variations in pressure and flow rate. This is particularly important in adhesive and sealant filtration where increased pressure may force particulates through the filter instead of removing them.

Types of Filters

In the process industries, the most common types of filters can be classified as having either a non-fixed, random-pore-size medium or a fixed, controlled-pore-size medium. Understanding the differences between the two types of media is important in predicting how each of the filters will perform during a filtration process. Filters with non-fixed, random-pore-size medium such as felts, woven yarns and packed fiberglass are constructed of media that contain pores of various dimensions that can enlarge with changes in flow rate and differential pressure. This type of filter is subject to particle unloading, channeling and media migration.

Filters with a fixed, controlled-pore-size medium are constructed in a manner that prevents the pores from enlarging under pressure and flow changes. Although these filters contain pores of varying sizes, their overall pore structure is controlled during the manufacturing process to assure quantitative removal of particles larger than a given size. With this type of filter, any particles released during impulse conditions should be smaller than those designated by its removal rating.

Particulate Removal

Different systems for rating filter-removal efficiency exist today. Two of the most common are the Nominal Rating and the Absolute Rating systems. Unfortunately, each manufacturer is free to utilize variations of the different testing procedures to assign the Nominal or Absolute Ratings of its specific filters.A Nominal Filter Rating is generally defined as an arbitrary micron value based upon the particle removal by weight of some percentage of all particles of a given size or larger. Common percentages used by various manufacturers include 98, 95 and 90 percent. This rating system bases results on gravimetric testing rather than actual particle counting. Problems associated with the Nominal Rating system include a poorly defined test procedure, removal percentages that may vary with manufacturer and test data that are not usually reproducible. It is not uncommon to find downstream particles larger than the micron rating of the filter.

An Absolute Filter Rating is generally defined as the diameter of the largest hard spherical particle that will pass through the filter under specific test conditions. Several recognized tests exist for establishing the Absolute Rating of a filter, and their choice may vary with manufacturers. However, in all tests, the filters are subjected to a particle challenge by pumping a known contaminant through the filter and measuring upstream and downstream particle counts. Only filters with fixed, controlled-pore-size medium can have an Absolute Rating.

Beta Ratios

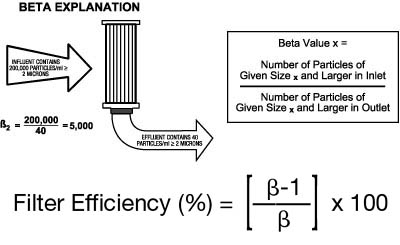

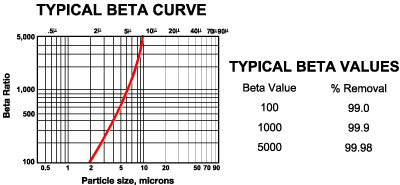

Beta ratios can be very useful in measuring and predicting the performance of Absolute Rated filters under specific test conditions in a variety of liquids (Figure 2). The Beta ratio concept involves measuring total-particle counts at several different micron levels in both the influent and effluent streams. These counts provide a profile of the filter efficiency at the different micron levels and can be plotted as a Beta curve for the given filter (Figure 3).

Selecting the Filter

In adhesives and sealants, many factors must be taken into consideration when choosing the filtration system. They include chemical and temperature compatibility, flow rate, acceptable pressure drop, degree of filtration and overall filtration cost. For systems that operate at ambient temperature, state-of-the-art cartridge filtration systems are almost always pleated. Depending upon the size of the batch, the filter system will normally use a #2-style pleated bag or a high-capacity cartridge filter (HCCF). High-temperature systems can require a metal filter cartridge similar to those used in polymer-manufacturing operations.Dirt-holding capabilities of metal filters vary widely. When considering total costs, one must consider both the mean time between change-out and the costs of cleaning the cartridge so that it can be reused. Cleaning can decrease throughput from flow rates achievable from the virgin metal cartridge.

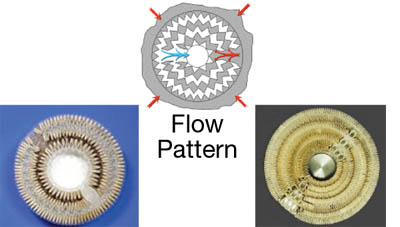

HCCF cartridges generally utilize staged pleated innards that are highly efficient and high capacity (HE/HC), and that maximize dirt-holding capacity in order to assure maximum time between change-out (MTBC). An HE/HC cartridge features segregated flow channels and flow chambers to optimize the Alpha Factor (Å) – a factor that is the key to determining total cost of filtration operations. Combining this design with the technique of pleating several different filter media together in a single pleat pack maximizes dirt-holding capacity. The design permits the use of many different types of filter media. This is essential for a wide range of fluid and temperature applications.

A cross-sectional view (Figure 4) details the basic design and flow paths of an HE/HC filter. This unique design works with either an “outside in” or an “inside out” flow path and is not limited to three rows of media.

The size of filter housings and pumps is usually dictated by the desired flow rate, pressure-drop limitations and required level of filtration. The recommended flow capacity of a filter element is used to determine the total number required for the desired flow rate. Housing size relates directly to the number of filter elements. Sufficient pump pressure must be provided to permit the desired flow rate through the filter element as it plugs so as to fully use the effective dirt-holding capacity of the filter.

Calculating Costs

Manufacturers often underestimate the true cost of the filtration operation. Total filtration costs must include both capital cost and daily cost/or batch costs to operate the system. Adhesive and sealant operations are almost always batch operations, and attaining proper filtration quality can vary depending upon the size of the batch. Specifically, a certain type of filter may be required to assure quality of the end product, but a small (100-gallon) batch may require the use of a filter element that could actually handle a large (2,000-gallon) batch. Yet, the same cleanup and downtime are required for both.Indeed, most engineers understand capital costs, but product pricing may not cover the true cost of operations and maintenance of the filtration system. It includes cost of labor and costs of installing, removing and disposing of the element. In those cases that require special breathing apparatus and protective clothing, the actual cost of the total filtration operation can be quite high. The cost of the filter element itself may be nominal compared to companion costs.

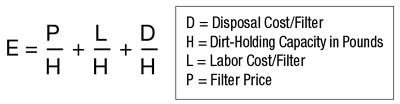

Filtration Cost Efficiency (E) is defined as the total costs, direct and indirect, that are associated with removing one pound of solids from a process stream. Direct cost is filter price; indirect costs include labor and disposal. A lower total cost results in a better efficiency rating. If we disregard equipment depreciation, we can express this relationship by the following formula:

Manufacturers should recognize that in small batches a filter might not reach its actual dirt-holding capacity in pounds (H) of the filter. This can dramatically increase the true cost of the filtration operation. By knowing dirt-loading requirements, the filter can be sized accordingly.

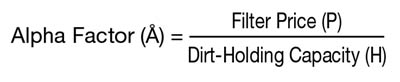

Both filter price and dirt-holding capacity are the dominant components in operating cost. The relationship between the two is defined by the following formula as the Alpha Factor (Å).

Combining the Alpha Factor formula with the Filtration Cost Efficiency formula provides an interesting result.

The indirect costs shown in the equation are reduced as the dirt-holding capacity of the filter increases. Therefore, the Alpha Factor becomes the dominant number in the equation. The lowest Alpha Factor results in the lowest filtration cost. One can see that wide variations in the H factor dramatically offset Å in order to achieve the same filter cost efficiency (E). With a small batch, one does not necessarily maximize filter life.

Maximizing Filter Life

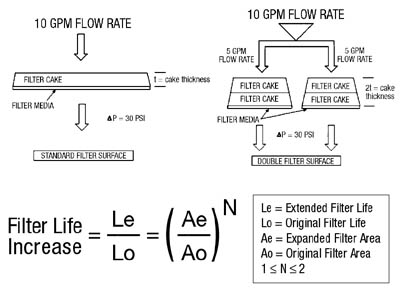

Filter life is directly related to a filter’s dirt-holding capacity. It can be defined as the total volume of fluid that passes through a filter before reaching the maximum operating differential pressure.Under a constant flow rate, the life of most Absolute Rated filters is significantly increased when their effective surface areas are increased. This property of filter life is a direct result of the relationship between flow density (gallons per minute per square foot) and the resulting differential pressure across the filter area. Under ideal conditions, the maximum increase in filter life is equal to the square of the increase in effective surface area. Doubling the effective filter surface area can increase filter life up to four times (Figure 5).

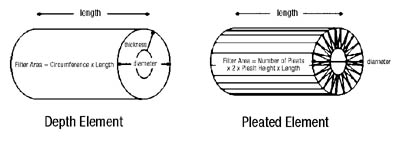

An easy way to increase filter life using an existing housing is to replace depth filters with pleated filters. In the diagrams shown in Figure 6, the surface area of the cylindrical depth element is much less than that of the pleated element.

In those facilities that make very large batches of adhesive, engineers should obviously consider the savings associated with filter-housing costs. Many plants design their filtration systems based on a maximum flow rate. If a 2.5” OD or 3.75” OD cartridge is used in calculating the base flow rate, a larger vessel will be required to meet the maximum flow requirements. Using an HCCF design will minimize the size and cost of the filter vessel required for specific flow rates and can result in significant cost reductions when high-pressure filter vessels are required.

Conclusion

Filtration in the adhesives and sealants industry deserves close attention at the plant level because costs can be significant. The filter operation may be an important factor in the actual pricing of the end product.· Quality control and filtration of incoming raw materials may be required.

· Vehicle filtration is extremely important to assure high quality of the end product, especially when the vehicle is manufactured on-site.

· Filter elements used in any system should be selected based on media that contain fixed, controlled-pore sizes.

· Beta ratios provide a profile of a filter’s efficiency at different micron levels.

· Total filtration operating cost must include equipment depreciation, costs for filter elements and their disposal, and labor costs, including element change-out.

· A filter element’s Alpha Factor (Å) is easy to calculate. The lowest Alpha Factor results in the lowest filtration cost.

· An increase in effective surface area or a reduction in flow rate will result in a significant increase in filter life.

Filtration costs are often an afterthought in the adhesives and sealants industry, yet filtration operations can dramatically affect the cost of any batch – especially high-priced specialty products. Filtration can hide real manufacturing costs that significantly affect profitability. Filtration must be considered in the overall pricing structure of all adhesives and sealants – especially those small batches that do not take advantage of the maximum dirt-holding capacity of the filter elements.

For more information:

Additional information on quality, high-efficiency filter elements is available from Filtration Technology Corp. (FTC), 5175 Ashley Court, Houston, TX 77041; phone 713-849-0849; fax 713-849-0202; or visit the Web site http://www.ftc-houston.com.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!