Making Learning Stick

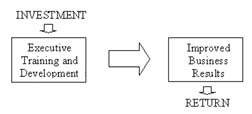

The challenge is getting the training and development to "stick." Too often, much of the benefit that ought to be realized is lost because the learning is not catalyzed into action. In highly competitive industries like adhesives and sealants, no company can afford to expend resources on learning and development only to have them dissipate.

To maximize the return on its training investment, a company first needs to ensure that new skills and knowledge are carried back to the job, transferred, and applied in a way that produces improved results. Both the learning and the transfer process must be optimized.

Six Disciplines that Make Learning Stick

Companies that generate the greatest return on their training investment manage the entire process by following the 6 Ds.™- Define the outcomes

- Design the complete experience

- Deliver for application

- Drive follow-through

- Deploy active support

- Document results

Taken together, these six disciplines sharply increase the stickiness of learning and development initiatives, and, hence, their return on investment.

Define the Outcomes

No competent chemist or chemical engineer embarks on the development of a new product without clearly defining the expected benefits. By the same token, no management team should allow a training and development program to go forward until the expected benefits to the business are clearly defined. What will participants do better or differently in their jobs? How will the benefits be measured? Defining the expected outcomes of a training and development program in business terms is a shared responsibility between management and the training and development department.Design the Complete Experience

Too often, training departments focus only on the event itself. To do so is short sighted. In the same way that the success of a surgical procedure is affected by the pre-surgical prep and -especially - the aftercare, the success of a training-development program is influenced by what happens before and after the training itself. No matter how effective the learning process, it creates value for an organization only through its application. And that necessarily happens after the formal program ends. As a result, whether a development program delivers its promised benefits depends in large part on what happens back in the workplace.

Focusing only on the classroom ignores the tremendous influence of the participant's manager on whether learning transfer takes place. If he or she is supportive, the new learning is likely to be used. If the manager is indifferent or disagrees with the program's precepts, the course content will be quickly abandoned - a waste for all concerned. Thus, the most effective programs include plans for post-course implementation that are as detailed as plans for the learning event itself.

Deliver for Application

For training and development to stick, learners must be able to make the connection between theory in the classroom and application on the job. Only then will their new knowledge benefit the company. There is a strong correlation between a learner's ability to recall information and whether she or he perceives it as useful. That depends on how the material is presented.Each topic should be clearly linked to current business issues and illustrated by relevant examples to ensure tight coupling between the classroom and the real work of the attendees. For the same reason that adhesives and sealants must be practical in a real-world environment, training and development must be practical in the real-world business environment.

Course designers should ask how the practical application of this principle will be illustrated. What opportunities will learners have to practice the skills? What has been done to ensure that trainers truly understand the business challenges faced by the participants? The more effectively the content is delivered with application in mind, the more the learning will adhere and be applied so that it delivers value.

Drive Follow-Through

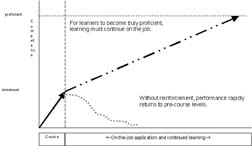

New knowledge is effervescent. Numerous studies have shown that unless new skills and knowledge are practiced, revisited, and reinforced on the job, performance rapidly falls back toward baseline. Much of the potential value evaporates.For this reason, the most effective programs actively ensure that what is learned is reinforced and applied before it degrades. No area has been more neglected, or offers greater opportunity for improvement, than the period immediately following formal training. Virtually every manager has attended a management-training program, gained new insights and written objectives to apply them only to put their notebook on the shelf and do nothing.

Effective companies avert this loss of potential by making sure that learning objectives are tracked, measured and earn recognition for their completion, just like other business objectives. They don't allow participants to write goals and then simply forget them.

For the past five years, the Fort Hill Co. team has been studying and developing follow-through management systems. One system makes certain managers receive copies of their direct reports' learning objectives, reminds participants of their goals, and asks them to periodically reflect on what they have learned and accomplished. Actively driving follow-through has led to greater effort, more managerial involvement, a higher level of achievement and improved return on investment.

Deploy Active Support

Companies must also ensure that there is support, as well as accountability, for follow-through in the post-course period. Participants are more likely to try new skills and approaches if they know management supports them.

Support from direct supervisors is especially important. At a minimum, they should know and endorse their direct reports' development objectives. Sadly, this happens infrequently. At one corporation, 60% of the managers admitted they had no idea what their reports were trying to accomplish following a week-long training program. Support for learning transfer should be part of a manager's performance evaluation, because without such support the investment in learning will be squandered.

Document Results

Finally, claims of improved performance require proof. Effective companies measure and evaluate the results of training and development programs to ensure that the investment is producing an adequate return for shareholders.Companies should hold their training and development organizations to the same standards of excellence as they do other departments. Stated differently, they should not accept measures of activity, such as number of courses or people trained, as substitutes for measures of productivity. Increasing the number of people trained is of value only if the training actually improves on-the-job performance. It is a matter of measuring the benefit to the business, not just the fact of activity.

Companies in the adhesives and sealants industry invest millions of dollars in training and development each year. Those that stay competitive manage the entire development process in a systemic and disciplined way. They ensure that the right things are learned, that learning sticks, and that it is applied to yield maximum return and competitive advantage.

For more information, contact Fort Hill Co., Montchanin Mills, Suite P, Rockland Road/Rt. 100, Montchanin, DE 19710; phone (302) 651-9223; or e-mail info@forthillcompany.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!