ADVANCING ADHESIVES: A Green Substrate Wetting Alternative

A new additive offers optimum substrate wetting performance while enabling the formulation of low-VOC aqueous adhesives products.

Troy Corp.’s multifunctional Troysol™ LAC provides excellent wetting of low-energy and contaminated surfaces, resulting in strong adhesive bonding. However, due to government regulations and consumer demand for environmentally compliant, green products, the company has introduced Troysol ZLAC to fill the gap. ZLAC is a zero-volatile organic compound (VOC), hazardous air pollutants (HAPs)-free, alkyl phenol ethoxylate (APE)-free version of the traditional LAC product. ZLAC offers the same optimum substrate wetting performance as traditional LAC, but also enables the formulation of low-VOC aqueous adhesives products.

Troy Corp.’s multifunctional Troysol™ LAC provides excellent wetting of low-energy and contaminated surfaces, resulting in strong adhesive bonding. However, due to government regulations and consumer demand for environmentally compliant, green products, the company has introduced Troysol ZLAC to fill the gap. ZLAC is a zero-volatile organic compound (VOC), hazardous air pollutants (HAPs)-free, alkyl phenol ethoxylate (APE)-free version of the traditional LAC product. ZLAC offers the same optimum substrate wetting performance as traditional LAC, but also enables the formulation of low-VOC aqueous adhesives products.

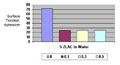

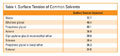

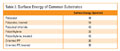

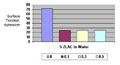

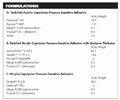

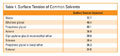

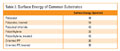

Troysol ZLAC was first evaluated for its ability to reduce surface tension, which is essential to enable complete wetting over low-energy substrates. Figure 1 shows how ZLAC was able to reduce the surface tension of water with use levels as low as 0.1%. Table 1 lists the surface tension values of typical solvents used in adhesives formulations. Conventional adhesive technology is based on solvents with low surface tensions. Conversely, aqueous adhesives require wetting additives to reduce the surface tension. The use of wetting additives enhances the coverage of substrates with low surface energy (see Table 2).

An adhesive with a high surface tension in the liquid phase will have poor wetting over low-energy substrates, resulting in craters and/or severe crawling. Troysol ZLAC, however, effectively reduces the surface tension of water to 25 dynes/cm, enabling aqueous adhesives to spread over low-energy substrates. Figure 2 shows a wetting test over a siliconized film. The formulation containing ZLAC provides complete coverage, while another formulation containing ethoxylated acetylenic diol, a commonly used wetting additive, showed severe crawling at equal concentrations.

An adhesive with a high surface tension in the liquid phase will have poor wetting over low-energy substrates, resulting in craters and/or severe crawling. Troysol ZLAC, however, effectively reduces the surface tension of water to 25 dynes/cm, enabling aqueous adhesives to spread over low-energy substrates. Figure 2 shows a wetting test over a siliconized film. The formulation containing ZLAC provides complete coverage, while another formulation containing ethoxylated acetylenic diol, a commonly used wetting additive, showed severe crawling at equal concentrations.

The following procedure was used for peel strength evaluation (180

The following procedure was used for peel strength evaluation (180

The use of zero-VOC Troysol ZLAC wetting additive has shown excellent substrate wetting efficacy equivalent to that of Troysol LAC when used in PSAs applied over low-energy substrates. ZLAC can help formulators achieve defect-free films with excellent surface appearance and optimum adhesion performance, without VOC contribution.

For more information, visit www.troycorp.com.

Robert Miller, Dale Lyman and Sheila Belding of Troy Corp. contributed to this article.

Editor’s note: Flexbond® is a trademark of Ashland Inc.; Aquatac® is a trademark of Arizona Chemical; Synthebond® is a trademark of Hexion; Tacolyn® is a trademark of Eastman; Acrysol® is a trademark of The Dow Chemical Co.; Acronol® and Collacral® are trademarks of BASF Corp; and Troysol™, Mergal® and Troykyd® are trademarks of Troy Technology.

Figure 1. Troysol ZLAC Enables Complete Wetting over Low-Energy Substrates

Figure 2. Troysol ZLAC Effectively Reduces the Surface Tension of Water

Enhancing Performance

Complete substrate wetting must occur in order to obtain a strong adhesive bond. Effective wetting additives reduce the surface tension of the adhesive, enabling complete coverage of the substrate. Effective wetting additives are especially important for low-energy surfaces, which would otherwise resist coverage. In addition, if a substrate is contaminated, low-energy contaminant particles repel the adhesive, resulting in surface defects and a weakened bond. When an effective wetting additive is present, adhesives will wet any contaminants and/or low-energy substrates, thus creating a strong, unimpeded bond.

Reducing Surface Tension

High surface tension makes water inherently poor at wetting most substrates. A good example of this high surface tension is when a metal pin floats on the surface of water.Troysol ZLAC was first evaluated for its ability to reduce surface tension, which is essential to enable complete wetting over low-energy substrates. Figure 1 shows how ZLAC was able to reduce the surface tension of water with use levels as low as 0.1%. Table 1 lists the surface tension values of typical solvents used in adhesives formulations. Conventional adhesive technology is based on solvents with low surface tensions. Conversely, aqueous adhesives require wetting additives to reduce the surface tension. The use of wetting additives enhances the coverage of substrates with low surface energy (see Table 2).

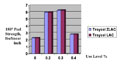

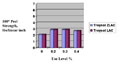

Figure 3. 180° Peel Strength of PSA Formulation A

Peel Strength Test

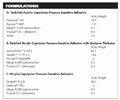

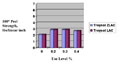

Peel strength tests are valuable for determining the strength of the adhesive bond between two materials. In order to evaluate the adhesive strength imparted by the wetting performance of Troysol ZLAC and LAC, peel strength tests were performed using three typical pressure-sensitive adhesive (PSA) formulations (see Formulations sidebar).

Figure 4. 180° Peel Strength of PSA Formulation B

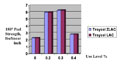

Figure 5. 180° Peel Strength of PSA Formulations A, B and C

Results and Conclusions

Test data show that substrate wetting imparted by Troysol ZLAC increases the peel strength in PSAs, and is the equivalent of the optimized performance offered by the traditional LAC product (see Figures 3 and 4). Both additives enhanced substrate wetting and increased peel strength, thereby imparting greater adhesive bonding and better film integrity. In addition, concentrations as low as 0.05-0.1% ZLAC provided a substantial increase in adhesion for formulations A, B and C (see Figure 5).The use of zero-VOC Troysol ZLAC wetting additive has shown excellent substrate wetting efficacy equivalent to that of Troysol LAC when used in PSAs applied over low-energy substrates. ZLAC can help formulators achieve defect-free films with excellent surface appearance and optimum adhesion performance, without VOC contribution.

For more information, visit www.troycorp.com.

Robert Miller, Dale Lyman and Sheila Belding of Troy Corp. contributed to this article.

Editor’s note: Flexbond® is a trademark of Ashland Inc.; Aquatac® is a trademark of Arizona Chemical; Synthebond® is a trademark of Hexion; Tacolyn® is a trademark of Eastman; Acrysol® is a trademark of The Dow Chemical Co.; Acronol® and Collacral® are trademarks of BASF Corp; and Troysol™, Mergal® and Troykyd® are trademarks of Troy Technology.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!