3-D Vision Enables Challenging Adhesive Inspection Applications

A new generation of 3-D vision systems is being used to automate the inspection of adhesive applications that cannot be addressed with conventional 2-D vision systems.

A new generation of 3-D vision systems is being used to automate the inspection of adhesive applications that cannot be addressed with conventional 2-D vision systems. The key advantage of 3-D vision in adhesive applications is the ability to determine the width, position, height and volume of the adhesive that has been applied.

Ensuring Windshield Quality

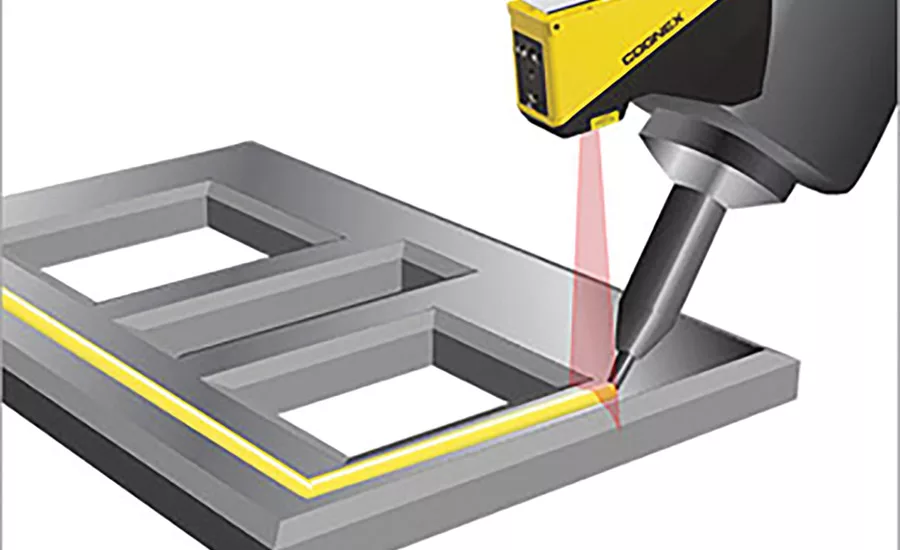

The newest 3-D vision systems use a combination of a laser that projects a line and an image sensor, both contained in a single industrial housing. The object to be measured is moved through the projected laser line, and the image sensor captures the displacement of that laser line to extract a 3-D point cloud of data used to measure 3-D features.

A typical application of 3-D vision is in applications where adhesive is applied to hold two components together or seal a joint against the elements. The position and amount of adhesive is often critical in these applications. For example, when silicone adhesive is applied to a cast housing for an automotive control module, the adhesive volume and position must be controlled to maintain a proper seal. It is often possible to determine the footprint of the adhesive using 2-D machine vision or a human inspector, but these techniques cannot accurately determine the volume of the glue. In addition, it can be a struggle to determine the glue’s features when the adhesive and the part or background are black on black. A 3-D vision system overcomes these challenges by determining the position and volume of the adhesive, making it easy to verify that the correct amount has been applied and that it is in the right position to seal the part.

In automotive manufacturing, 3-D vision is being used to improve adhesive application for automotive windshield assembly. Automotive manufacturers use robots to pick up a glass windshield, apply an adhesive bead to the windshield’s edge, and transfer the glass to an offload station where an operator installs it on the vehicle. Typically, a mechanical centralizer locates the glass at points around its edge, and the robot moves to a known location to access the glass. Since the windshield does not always sit in the same position, mechanical centralizers have difficulty adapting to different glass sizes when new vehicle models are introduced.

Machine vision provides a scalable solution for windshield glue bead installation. During the windshield application, the manufacturer uses a vision system* over the part and a 3-D laser displacement sensor mounted on the robot applying the adhesive. The user trains the vision system to recognize a unique feature on each windshield. The vision system then provides location information to the robot and associates the part with the glass model number.

Once training of each windshield model is complete, the user then establishes communication with the robot. The robot manipulates the windshield and presents the edge of the glass to a fixed nozzle, which applies a continuous bead of sealant. The 3-D laser displacement sensor can inspect the sealant in two ways. The first is at the application-specific level, when the sensor is mounted on the robot, or nozzle, inspecting the adhesive bead to make sure it is properly applied and within the right amount. The second approach is to mount the sensor to a fixed location and take advantage of the sensor’s measurement range to scan the part as a whole while also determining the bead’s volume and location. Once complete, the robot transfers the glass to an offload station where the operator picks up the windshield and adds it to the vehicle. The vision system and 3-D displacement sensors provide scalability for new glass models to be added quickly, which significantly reduces production line downtime and part changeover compared to the mechanical location method.

Critical to the successful deployment of a 3-D vision application is having the right hardware, vision tools, development environment, and communication to the factory floor; all of these components also should be assembled and tested as a complete solution. Typical 3-D vision tools include a plane fitting to establish a base and 3-D volume tool to determine the volume or a cross-sectional area tool to determine the position, width, and height of the bead.

Process Improvements

A growing trend in automotive adhesive applications is to perform increasing numbers of 3-D analyses of objects, because it provides data and information that cannot be obtained from 2-D alone. The new generation of 3-D vision systems can automatically inspect adhesive applications that are not well-suited to 2-D machine vision and manual inspection. These newer systems can generate a calibrated, topological representation of the part that can be used to measure 3-D features such as length, width, height or volume relative to any surface and yield results in real-world units (millimeters or inches). The data provided by in-line measurement is another major advantage that often enables quality managers and engineers to rapidly improve the process of applying adhesives in automotive manufacturing.

For more information, phone (877) 264-6391, fax (508) 650-3344, email pr@cognex.com or visit www.cognex.com.

*Cognex In-Sight®

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!