Testing the Rheology of Adhesive Materials

Manufacturers of adhesive materials conduct various physical property tests to develop performance specs for their products.

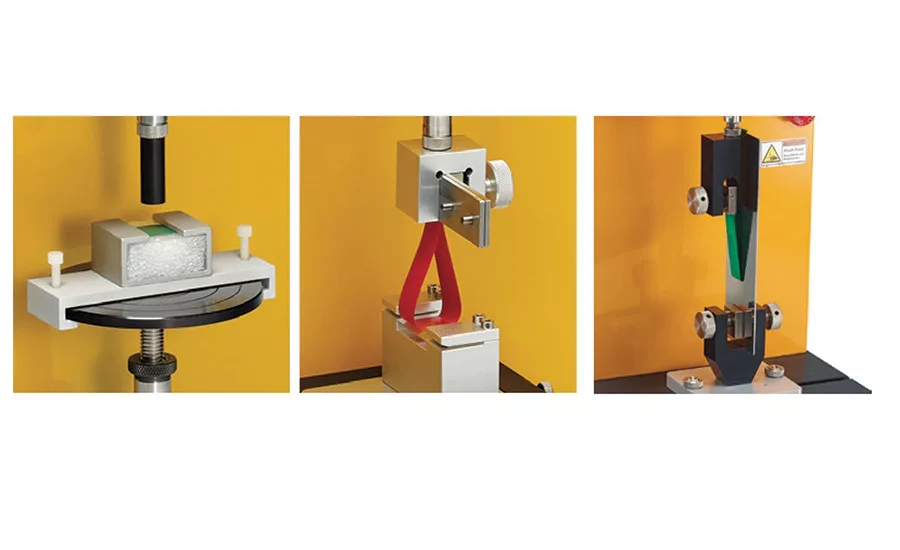

From left: adhesive tack tester, loop tack tester, and 180° peel fixture.

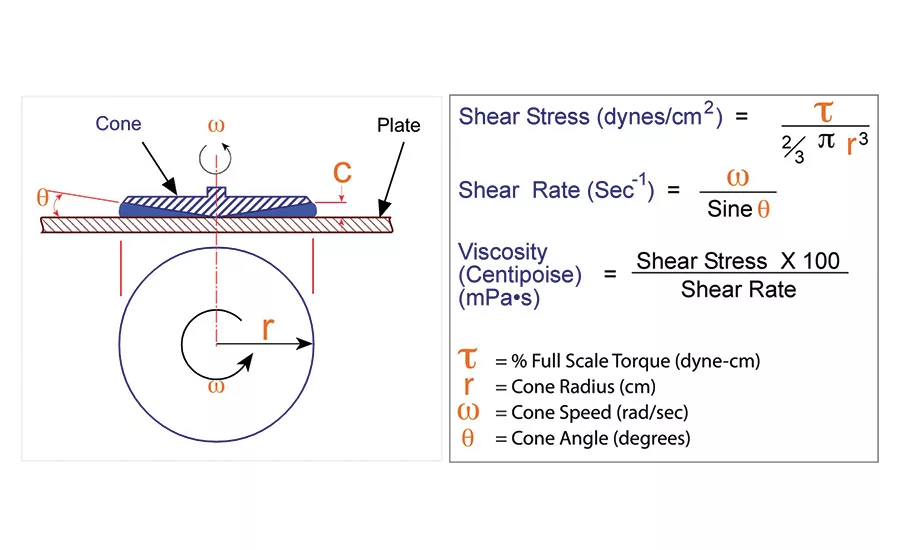

Figure 1. Sample material sandwiched between plate and cone spindle.

Figure 2. Yield stress determination testing of four adhesives.

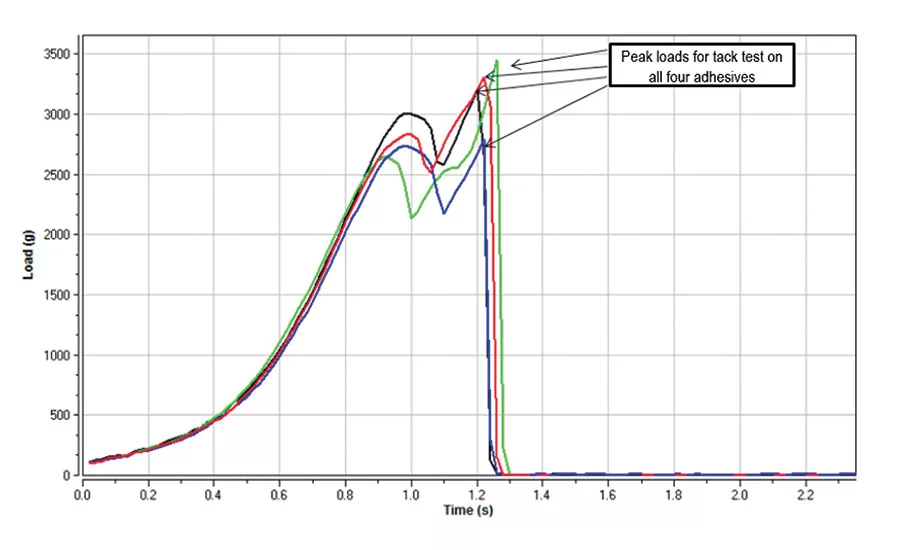

Figure 3. Tension test data quantifies bonding force of adhesive materials.

Vane spindle options.

Ease of application when removing the product from a container and initial bonding force after placement are two critical adhesive behavioral properties. Viscosity and yield stress are measurable properties that quantify the former; tack and cure time the latter. Manufacturers of adhesive materials conduct various physical property tests to develop performance specs for their products, and Quality Control runs some of these tests on each batch to certify whether performance will meet customer expectation.

Viscosity Testing

One practical tool for evaluating viscosity and yield stress is the controlled stress rheometer with cone spindle, which has a temperature-controlled sample plate that conditions the adhesive before testing. The cone plate model normally requires a small sample size, usually 2 mL or less, to run tests. If the material viscosity is exceptionally high, it may be necessary to use a plate spindle (flat surface relative to horizontal compared to slightly angled surface for cone spindle). This approach requires more material, depending on the set distance between the sample plate and spindle. Sample size may range from 2 to 10 mL. Adhesives that have filler materials will generally necessitate a larger gap size to allow free migration of particles during the rotation of the spindle (see Figure 1, p. 22).

If a sufficient quantity of test material is available, then a soft solids tester rheometer with vane spindle may be an appropriate choice. Vane spindles come in a variety of sizes, with blades that range from 5-40 mm in width and 10-80 mm in height. Large spindles are used for testing lower viscosity adhesives (below 50 K cP), while small spindles are effective for measuring high viscosity (100 K cP and higher).

Another consideration is the container that holds the adhesive material. When evaluating tubes of adhesive, for example, standard practice is to cut the tube in half and insert a spindle that has blade diameter half the dimension of the tube.

The rheometer shears the adhesive material by running a controlled torque ramp when using a cone spindle and a controlled speed ramp when using a vane spindle. The application of increasing force gradually allows the cone spindle to begin rotation when the yield stress in the material is exceeded. This quantifies the force that a user would exert to expel the adhesive from a tube. The scientific unit of measurement is Pascals, which is essentially a force per unit area related to the shearing action by the adhesive acting on the surface of the cone spindle. The soft solids tester rotates the vane spindle at a relatively low rpm, perhaps 0.5 or 1.0, which means that the material is actually moving at the start of the test. The torque sensed by the vane as it pushes on the material increases steadily until a maximum value is reached. This peak value is by definition the yield stress.

Figure 2 shows graphical data for four different adhesive materials measured by the soft solids tester with a vane spindle. Stress in Pascals is plotted on the Y-axis, strain in non-dimensional units is on the X-axis. The initial upward slope of each curve going from left to right, also referred to as “modulus,” is quantified numerically and indicates the “stiffness” of the adhesive material, or its initial resistance to movement.

Sample D is less stiff than the others, comparatively speaking. The maximum stress value for each sample is the yield stress. Sample A has the highest yield stress. The advantage of using graphical analysis for yield stress testing is the ability to superimpose limit values on the data that clearly show pass/fail performance.

Evaluation of Bonding Properties

Evaluation of bonding properties is best accomplished with a universal tester, which is an instrument that can pull materials apart using tensile force. A texture analyzer is a type of universal tester that operates at relatively low force levels; it can effectively measure tack and curing when working with small cross-sections of bonded items. Many types of fixtures have been designed for use with texture analyzers to measure adhesive force.

The easiest fixture to set up and operate with the texture analyzer is the adhesive tack tester. The substrate coated with adhesive material is secured in a fixture that holds it firmly in place. A cylindrical test probe moves in a downward direction, makes contact with the substrate material, and applies a defined load for a fixed time interval. Applied forces can range from a few hundred grams to several thousand grams; the choice of load will depend on the bonding action that is being simulated. When the probe retracts from the substrate, the user defines the speed for probe withdrawal. The instrument measures the amount of force needed to separate the probe from the substrate.

The rate of speed at which this occurs will have a direct effect on the peak force value. Some experimentation is needed to determine the appropriate speed. If the speed is too fast, the instrument may overload because the capacity of the measurement load cell has been exceeded. It is important that sufficient characterization is performed by R&D before the method is transferred to QC.

Once an acceptable procedure has been established, the test can be repeated for different hold time intervals to evaluate the change in bonding strength with increasing cure time. The overall objective is to develop a representative method for what actually happens to the materials in practice. It is therefore important to carefully simulate the real-life conditions as much as possible.

When evaluating the four adhesive materials shown in Figure 2, the adhesive tack tester used a withdrawal rate of

0.1 mm/sec for the cylindrical probe after applying a downward force of 500 g for 30 sec. The curing action during that time allowed the bonding force between probe and substrate surface to increase rapidly. The measured loads during probe removal were significantly greater than the initial 500 g force, ranging from 2,700 to almost 3,500 g. This quick test gives an effective indication of the curing action for each adhesive material.

R&D will very likely perform more extensive tests with longer bonding time intervals to evaluate the ultimate strength of each adhesive when fully cured. By contrast, QC needs a relatively quick test that confirms the adhesive is behaving correctly so that product can be packaged and shipped.

Both the controlled stress rheometer and texture analyzer are frequently seen in test labs for adhesive material manufacturers and in QC labs for companies that assemble materials into final products (e.g., window and door manufacturers). This type of testing equipment can eliminate rejected batches of adhesive material as a result of performance not meeting specification. The sure way to know that the adhesive is doing the job is to measure its flow properties, namely yield stress and viscosity, as well as its bonding strength with a tack test. ASI

For more information, phone (800) 628-8139 or (508) 946-6200, or visit www.brookfieldengineering.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!