Using Novel Emulsion-Based Pressure-Sensitive Adhesives in High-Performance Applications

New pressure-sensitive adhesives have been developed that can rival existing solvent acrylic and radiation-curable technologies used in high-performance tape and label applications.

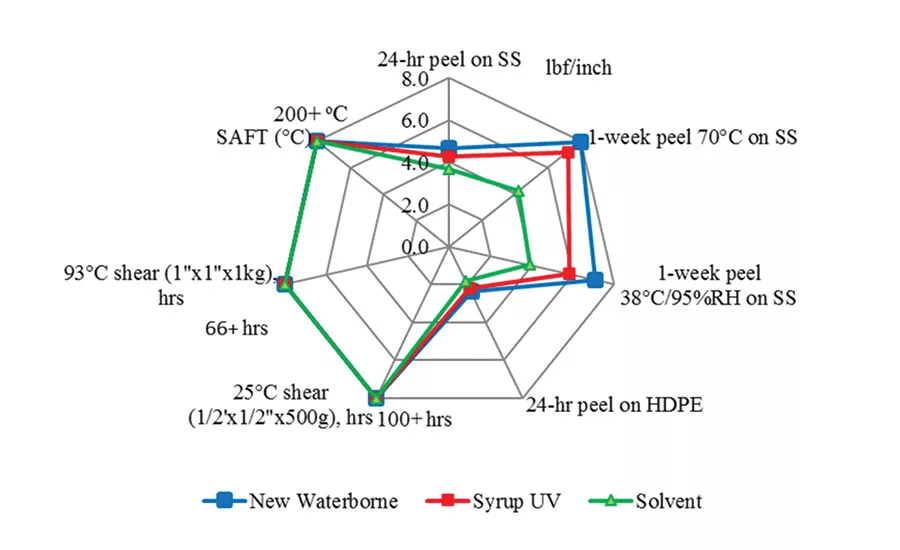

Figure 1. Comparison of the new emulsion PSA vs. syrup UV and solvent PSA.

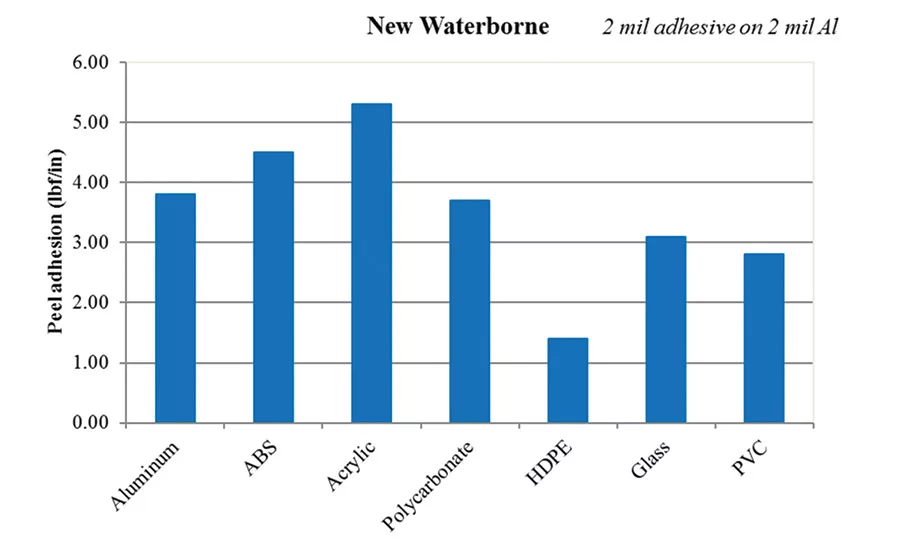

Figure 2. Peel adhesion comparison on various substrates (90˚ peel with 72-hr dwell).

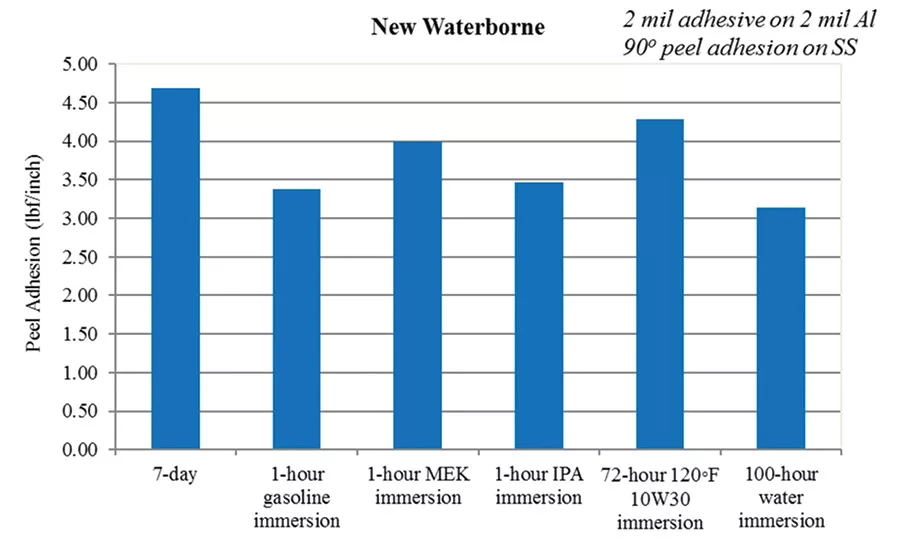

Figure 3. Comparison of fluid immersion test (90˚ peel with 7-day dwell).

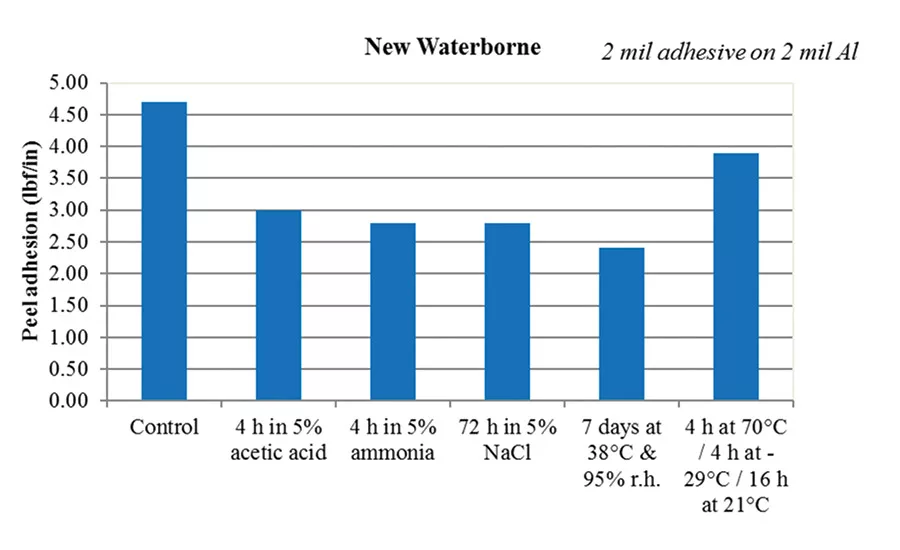

Figure 4. Chemical resistance and temperature cycling (90˚ peel with 7-day dwell).

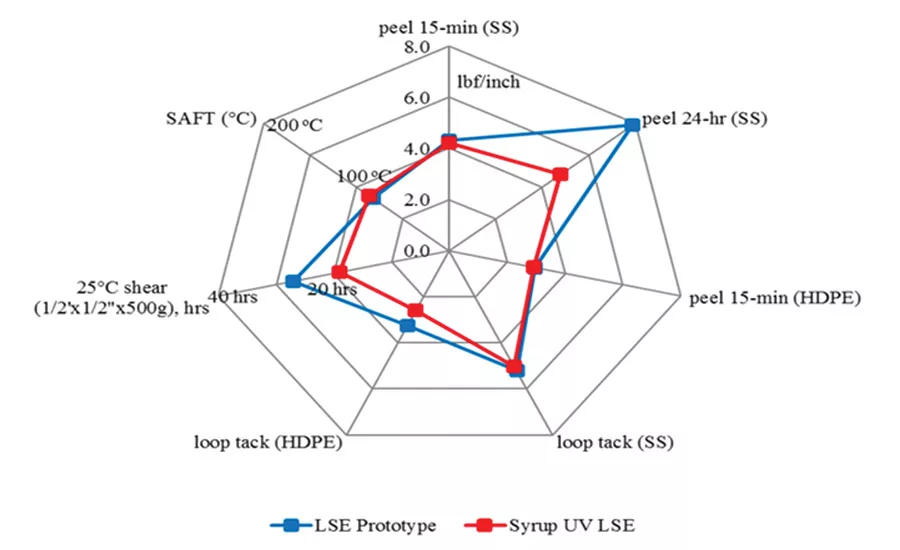

Figure 5. Comparison of the new LSE prototype PSA vs. syrup UV LSE PSA.

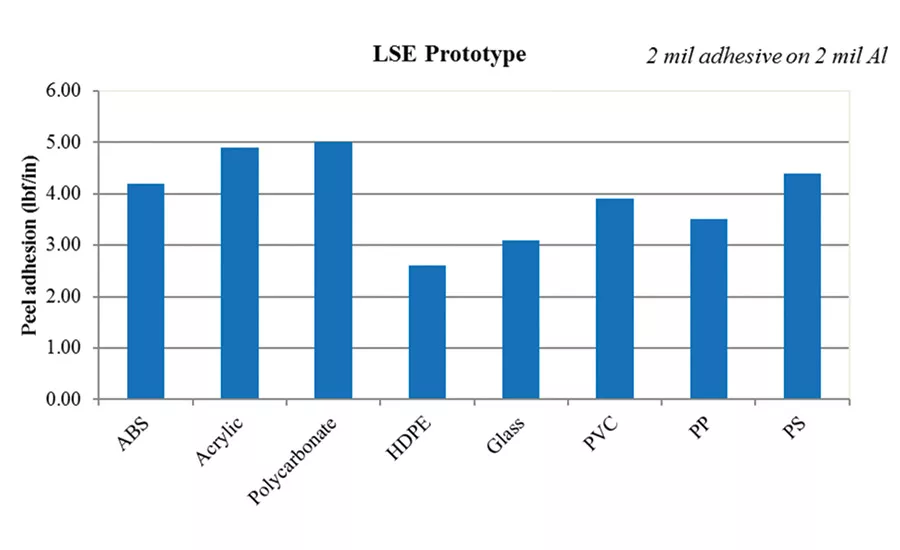

Figure 6. Peel adhesion on various substrates (90˚ peel with 72-hr dwell).

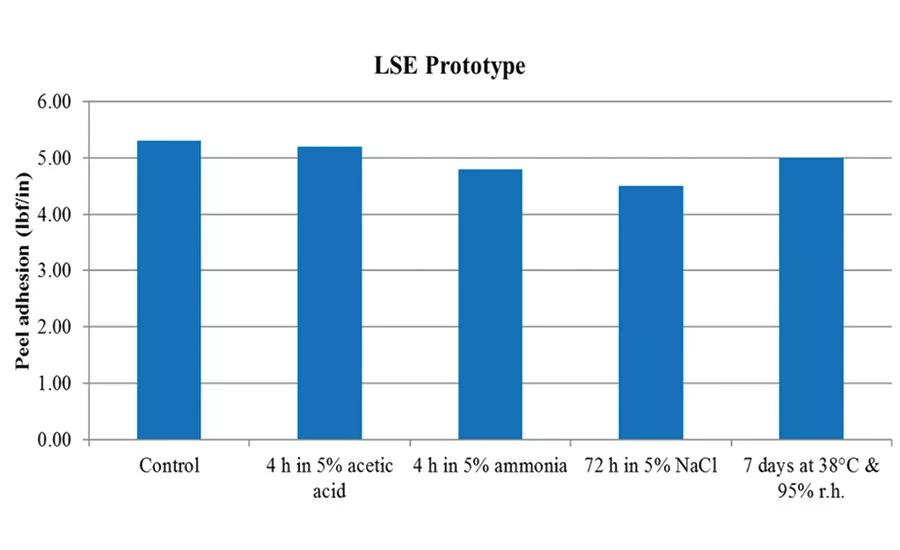

Figure 7. Peel adhesion of fluid immersion test (90˚ peel with 7-day dwell).

Figure 8. Chemical resistance and temperature cycling (90˚ peel with 7-day dwell).

Pressure-sensitive adhesives (PSAs) have become more popular in demanding tape and label applications. Many high-performance PSA applications are dominated by solvent acrylic PSAs and radiation-curable PSAs because they can achieve much higher cohesive strength and heat resistance than other technologies, including typical emulsion PSAs. Due to these performance limitations, waterborne emulsion PSAs are used in less demanding applications.

Waterborne acrylic PSAs provide many advantages such as high solids, lower cost, low hazard, and environmental benefits. With these advantages, industry has been pushing the limits of emulsion technologies to close the performance gaps between emulsion and other high-performance technologies.

A new waterborne technology with excellent adhesion and high-temperature properties has been developed that can rival existing solvent acrylic and radiation-curable technologies that are currently used in high-performance applications. The high temperature resistance is measured by shear adhesion failure temperature (SAFT; PSTC-17 test method), which has been the biggest limitation of waterborne PSAs vs. radiation-curable and solvent acrylic PSAs.

Adhesive Properties

Different types of crosslinkers and functional monomers can have various impacts on peel adhesion and high-temperature performance. With waterborne emulsion PSA being a heterogeneous system, the crosslinking can be intra-particle, inter-particle, or both after evaporation of water and the polymer particles start to coalesce. Unless care is taken in designing the crosslinking chemistry of the emulsion polymer, a non-uniform network can form, leading to unpredictable or inconsistent performance.

The new prototype waterborne emulsion PSA was developed having superior adhesion and high SAFT properties. It was benchmarked with a high-performance, radiation-curable acrylic PSA (syrup UV) and a solvent acrylic PSA.

Waterborne Emulsion PSA

Semi-batch emulsion polymerization was used for the base polymer for the emulsion PSA study. The base contains 2-ethylhexyl acrylate, butyl acrylate, methyl methacrylate, styrene, and acrylic acid with a calculated glass transition temperature (Tg) of -40˚C. The test samples were prepared by coating on a 2-mil PET film, air dried for 30 min, and then dried at 110˚C for an additional 3 min. The dried adhesive coat weight was 50 grams/m2.

The adhesive films were cut into ½- and 1-in. strips for peel adhesion, cohesion, and SAFT tests. As shown in Figure 1, the new prototype emulsion PSA has comparable adhesion performance and SAFT vs. the radiation-curable acrylic PSA (syrup UV) and solvent PSA.

With many tape applications requiring bonds to various substrates, the new emulsion PSA was tested on selected substrates. These tests were done with 2-mil aluminum foil backing and tested with 90˚ peel after a 72-hr dwell on the substrates. The new waterborne adhesive provided excellent adhesion to various substrates.

The new emulsion PSA was also tested for immersion in common fluids, including water, gasoline, methyl ethyl ketone (MEK), isopropyl alcohol (IPA), and 10W30 motor oil (see Figure 3). This test was done on a 2-mil aluminum foil backing and tested with 90˚ peel. The emulsion PSA showed great performance and peel retention after immersion and no recovery.

Figure 4 shows the chemical resistance and temperature cycling of the new emulsion PSA. These tests were done with a 7-day dwell on stainless steel plates.

Low-Surface-Energy Emulsion PSA

Many high-performance applications require bonding to low-surface-energy (LSE) substrates such as high-density polyethylene (HDPE) and polypropylene (PP). To achieve LSE bonding, a new emulsion PSA was tackified to develop a new LSE prototype emulsion PSA. The new LSE prototype has excellent adhesion to LSE substrates while retaining high shear and tack. It was benchmarked with a LSE tape using UV syrup technology, as shown in Figure 5.

The LSE prototype PSA achieved good adhesion to many different substrates (see Figure 6). Figures 6 and 7 show that the LSE prototype PSA has excellent peel adhesion retention after fluid immersion, chemical resistance, and temperature cycling tests.

Possible Applications

Many high-performance tapes require a balance of high adhesion and excellent cohesion. With high SAFT properties and excellent adhesion, the new emulsion acrylic PSA can be used for many applications where typical emulsion acrylic PSAs have not traditionally been used.

Foam bonding applications can be a challenge, even with solvent and UV syrup PSA products. With corona treatment of foams, the new waterborne PSA and LSE prototype show foam tear with a wide range of polyurethane and polyethylene foams of various densities. Even with no corona treatment, softer grade polyurethane foam tests showed foam tear. This provides a viable alternative to solvent and UV syrup PSAs in this application.

Formulation of waterborne products can be customized to run on different coaters and can be manufactured with much higher solids than typical solvent-based adhesives. Since emulsion adhesives do not typically contain flammable solvents, these adhesives also provide the advantage of not having to monitor lower explosion limits (LEL) during the drying process. In addition, solvent oxidation or elimination processes are not necessary. Together, these will allow the new emulsion adhesives to be coated faster and more safely than typical solvent-based PSAs.

For internal automotive applications, high volatile organic compound (VOC) content in the finished product can cause fogging problems and therefore cannot be used. Some preliminary data for VOC content and fogging tests using the dried film of the new emulsion adhesive show that this adhesive has similar VOC and fogging numbers to best-in-class products used in these applications.

Future Development

Additional technology developments in lowering VOCs and outgassing of the emulsion adhesives will open up new applications in aviation, electronics, and other automotive markets. With economic advantages and versatile formulation opportunities, as well as environmental advantages, additional high-performance applications opportunities using new emulsion technologies can be explored.

For more information, contact the author at (864) 253-8283 or yong.park@synthomer.com, or visit www.synthomer.com.

Author’s Acknowledgements: The author would like to recognize the input of Jong Guo, Brian Maxwell, and Graeme Roan, as well as experimental work done by Robert Dill, Allaxis Gist, and Jason Tucker.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!