Nouryon to Use Digital Technology from Semiotic Labs to Boost Plant Reliability

The technology has been successfully implemented at Nouryon’s chlorine plant at Ibbenbüren, Germany, and will now be rolled out to seven other sites in Europe.

Nouryon has signed a framework agreement to implement self-learning technology developed by Semiotic Labs that helps predict when to maintain and replace pumps and other rotating equipment. Semiotic Labs was one of the winners of Nouryon’s 2018 Imagine Chemistry open innovation challenge. The technology has been successfully implemented at Nouryon’s chlorine plant at Ibbenbüren, Germany, and will now be rolled out to seven other sites in Europe.

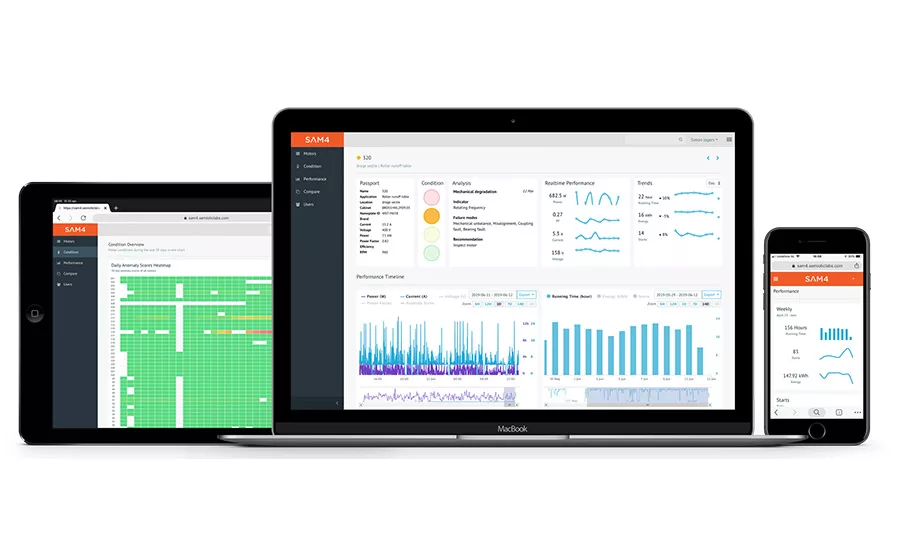

The technology uses electrical waveforms that can reportedly accurately predict 90% of upcoming maintenance needs in rotating equipment such as pumps, compressors, and conveyors up to five months in advance. This provides companies with the time to repair or replace critical equipment during planned stops, preventing unexpected interruptions to production and improving reliability of supply and process safety.

“Working with start-ups like Semiotic Labs allows us to tap into novel technologies that can provide significant benefits,” said Marco Waas, Nouryon’s director of R&D and Technology Industrial Chemicals. “Our customers rely on us for a reliable supply of essential raw materials and this predictive maintenance solution can greatly help improve the performance of our plants, while decreasing cost.”

Nouryon and Semiotic Labs will also look at ways to generate more value from waveform analysis by developing features that will enable significant reductions in CO2 emissions. The first large-scale implementations are planned for early 2020.

For more information, visit www.nouryon.com and www.semioticlabs.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!