Exploring Sausage Packages for Commercial and DIY Mastics

Many mastic users are either unaware that the sausage package option is available or they find it is not available in the brand they prefer.

Figure 1. Mini sausages do not take in air as they dispense product, keeping the mastic fresh and stopping it from drying out.

Figure 2. The applicator is integral to the opening design in mini sausages, obviating the need for plastic tools.

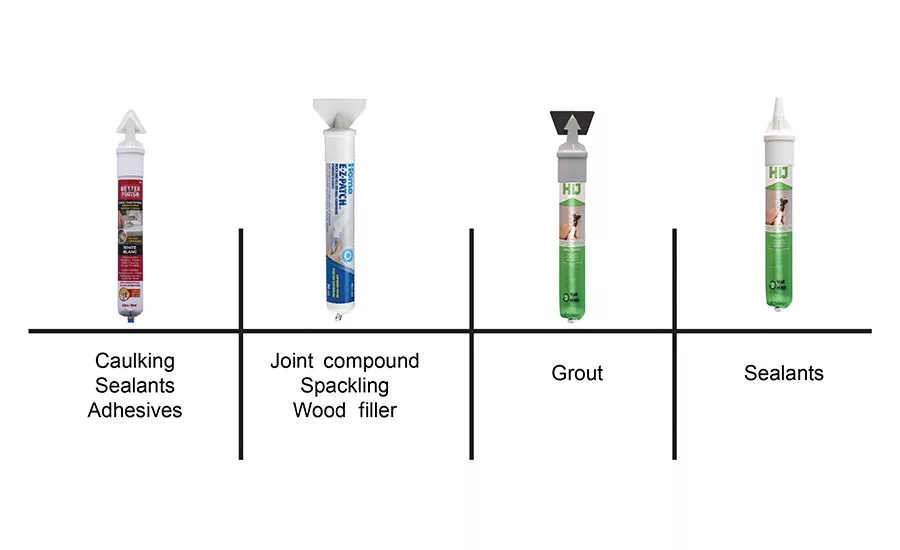

Currently, mastic is available to commercial and DIY consumers primarily in squeeze tubes and 10-oz cartridges. Although the sausage packaging format exists as an alternative, in a 20-oz size and a smaller “mini” option (2-3.5 oz), its availability is limited—as a stroll down the sealant aisle of Home Depot or Lowes will confirm. This lack of availability is due to low demand, and demand is lagging because users are either unaware that the sausage option is available or they find it is not available in the brand they prefer.

This negative feedback loop has produced an unfortunate stalemate in the industry, slowing further development, marketing, and education for the sausage option. The stalemate could be broken if the mastic supply chain recognized the advantages of supporting sausages as opposed to single-use plastic 10-oz cartridges and squeeze tubes.

Sustainability Advantages

The first major argument for the sausage is its eco-friendliness. Single-use plastic is a serious issue for our environment that is pushing governments in the direction of banning many products in that category, including bags, straws, cutlery, and plates. In the sealant and adhesive industry, squeeze tubes and cartridges contribute to this problem. For example, single-use plastic cartridges take up the volume of 80 Titanic ships per year in landfill worldwide (2.5 billion cartridges).1

In view of this landfill footprint, it’s only a matter of time before these forms of packaging become a product category of interest for environmental regulation. Moreover, government initiatives are being discussed that would make the manufacturer responsible for end-of-life management. As the environment becomes a bigger and more urgent issue, consumers are also actively seeking and choosing ecologically responsible options of all kinds; an eco-friendly format for mastic packaging will be attractive if they know about it and can find it.

Alternatively, a 20-oz foil sausage eliminates 97% of the landfill waste generated by two single-use plastic 10-oz cartridges—and the remaining 3% is recyclable. Two 10-oz cartridges occupy 15 times the landfill space of a 20-oz sausage, even assuming that no sausage foil is recycled (see Table 1).

Additional Benefits

The sausage format also lowers costs, particularly when one considers the complete “cradle-to-grave” supply chain cycle. For the mastic manufacturer, the unit cost for 10-oz empty cartridges is 30% more than the cost of sausage foil for the equivalent amount of product, and the cost of shipping the cartridges is seven times higher.

At the job site, disposal costs for the user are eight times greater for used cartridges compared with sausages, and the landfill space for them is 15 times more costly. The savings are less pronounced for the smaller sausages (1-in. diameter, 2-3.5 oz), but still worth considering. If some or all of these savings are passed on to consumers, pricing can become an advantage to supplier and customer alike.

Sausages result in less waste of the adhesive or sealant product, which is also a draw for consumers. In the case of the smaller mastic tube format (squeeze tubes), the biggest complaint DIYers have is premature drying out, especially after initial opening. The parallel size in the sausage format (the “mini”) does not dry out after opening and will stay fresh for years, provided the plug is reinserted. The manufacturing process for the sausage is a closed air-free system that eliminates virtually all air from the fill.

In addition, since foil has no memory, it is not prone to allowing air into the vessel as the mastic is dispersed (see Figure 1). Single-use plastic squeeze tubes, on the other hand, have a memory; once squeezed, they bounce back to their original form, drawing in air to fill the void. This accelerates the hardening of the mastic, as air is the catalyst for the hardening reaction.

A Dutch study analyzing both single-use plastic squeeze tubes and 10-oz cartridges prepped for landfill sites showed that, on average, 65% of mastic remains in the tube or cartridge, hardened and of no further value. By way of contrast, the mini sausage format would not be in the landfill until the product is fully utilized, eliminating the additional landfill waste. This particular advantage of the mini sausage could, with little development, be easily transferred to the larger 20-oz sausage format.

A further advantage of the mini sausage is that the applicator is integral to the opening design, obviating the need for plastic tools (see Figure 2). In addition to providing a convenience for consumers, this also eliminates still more plastic use and associated landfill volume.

Sausage Adoption

On the face of all this, switching to sausages should be a very easy decision. However, many customers don’t realize the sausage is an option because it isn’t currently widely available. Compared to the few mastic sausages available, there is an overwhelming preponderance of the 10-oz single-use plastic cartridges. If the consumer—either the commercial contractor or the DIYer—were to demand more 20-oz mastic sausages, the industry would respond. The ball is in the manufacturers’ court, because the customer must first be aware of the option and experiment with using it.

Brand loyalty is very strong with consumers, and it takes a significant number of forks in the road to alter historic user choice. In the current mature mastic market, however, early adopters on the supply side will soon bear the fruits of increased market share. If an early-adopter consumer, accustomed to buying a particular brand, were to try the sausage option offered by a competing brand because of its ecological advantages, they might also find a better cost-performance ratio—particularly with the mini because of the reduced product wastage due to premature hardening. If they do, they will very likely switch to the new brand.

Gaining market share generally has its costs at the outset. In this case, the advantage of producing the new sausage format is that it’s not necessary to reduce margin in order to attract new consumers, because the costs associated with shipping and manufacturing are lower. In addition to ecological responsibility and superior performance, manufacturers can choose to offer a lower price without affecting margin. Meanwhile, companies also provide more options for their existing loyal user base; with ecological responsible market approaches, strong brands only strengthen further. Late adopters on the supplier side, on the other hand, might never get their lost customers back. Once a customer switches for a better solution, it is very difficult to bring that customer back to the original brand.

In short, being on the early part of the adoption curve and offering a superior, eco-friendly, and possibly lower-priced mastic solution for the commercial and DIY marketplace will be a competitive advantage. In Canada, Home Hardware retails its own version of the mini sausage, and Richards Tools distributes its own version to Canadian retailers and wholesalers. American supplier Hyde Tools, Inc. supplies mini sausages to the wholesale and retail markets in the U.S. and Australia. These companies have been pioneers in promoting and raising the profile of the sausage option.

A Viable Option

Many ecological sustainability initiatives throughout the industry have resulted in gains of 5% here or 2% there. Design updates such as thinner walls for tubes and cartridges, less packaging, and slightly better screw tops to reduce premature hardening are all good advancements, especially when manufacturers see a reasonable return on investment.

To put things in perspective, the sausage represents a 3,000% improvement. If we replace cartridges alone with sausages, we could shrink the associated landfill space of 80 Titanics to 2-2/3 Titanics. Add to that the reduction in manufacturing costs and product waste, as well as the attraction of all of these features to consumers, and it becomes clear that sausages offer a viable packaging option for mastic manufacturers.

For more information, contact the author at (519) 485-5731 or dmckenzie@ingersollproducts.com, or visit www.ingersollproducts.com.

Reference

- “Get Rid of Caulking Tubes,” Tweha, June 30, 2018, www.tweha.com/en/get-rid-of-caulking-tubes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!