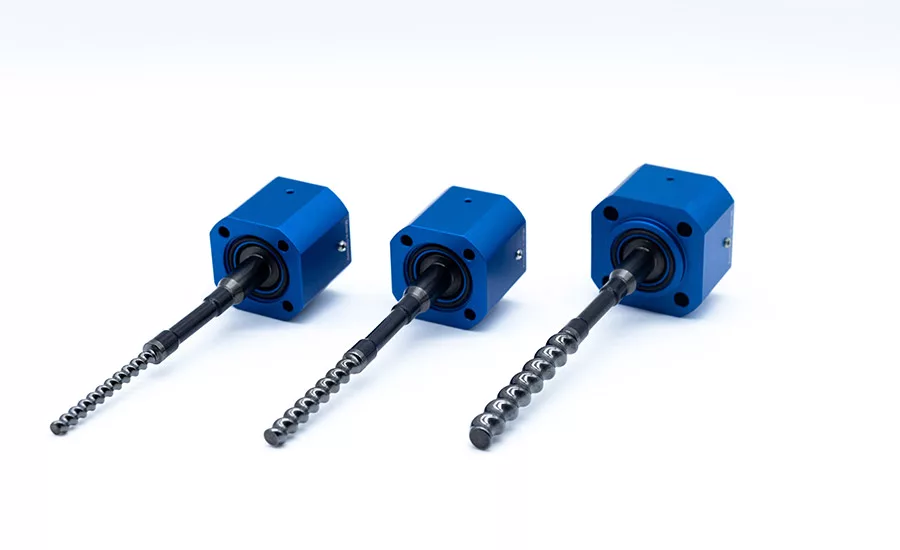

VISCOTEC: Diamond-Coated Dispensing Rotor

Rotors refined with a so-called “diamond coating” (DC) can reportedly double or triple the lifetime of the system until the rotor must be replaced.

preeflow by ViscoTec has developed a solution to significantly improve the service life of the dispensing system when processing highly abrasive materials, especially in small quantity ranges. The company reports that, following intensive development work and after a wide range of field and long-term tests, specially coated rotors proved to be the best technical and commercial solution.

Rotors refined with a so-called “diamond coating” (DC) can reportedly double or triple the lifetime of the system until the rotor must be replaced. In laboratory settings, working with a widely used and highly abrasive 2-component gap filler, the service life could even be improved significantly beyond that. This offers numerous advantages, including:

- Improvement of process reliability through a volumetric dispensing system

- Cost reduction due to reduced spare part requirements

- Reduced setup and downtimes

- Safer and easier handling compared to ceramic rotors

- Drop-in replacement; no additional technical adjustments required

Solids-laden fluids, or filled materials with highly abrasive properties, are currently gaining in importance and will do so in the future. These are mostly thermally or electrically conductive materials in the 1- and 2-component range. Particularly frequent are applications with thermal gap fillers or thermal conductive pastes, which are becoming increasingly important due to the continuing boom in the area of electronics and circuit board production, from small wearables to smartphones and tablets to electric vehicles.

The abrasive properties of such materials are particularly challenging for the dispensing equipment and can lead to severe and premature wear. By selecting the most suitable setup and parameters, the service life can be optimized with standard equipment, but the rotor and stator wear faster than usual and need to be replaced.

The rotors with diamond coating are now available for eco-PENs and eco-DUOs in sizes 330, 450, and 600. Additional details are available at www.preeflow.com and www.viscotec.de.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!