UV LED Curing for Adhesives, Sealants, and Coatings

UV LED curing technology offers lower operating costs than traditional technologies, as well as long lifetime, enhanced system capabilities, and environmental benefits.

The combination of high-energy UV LED sources with the appropriate adhesive enables increased productivity while also providing the ability to cure heat-sensitive materials.

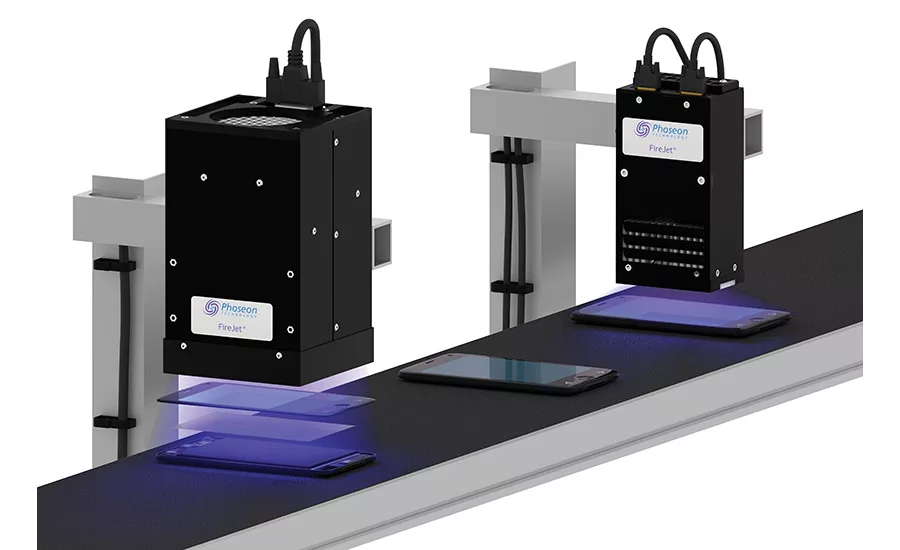

Figure 1. UV LED curing process.

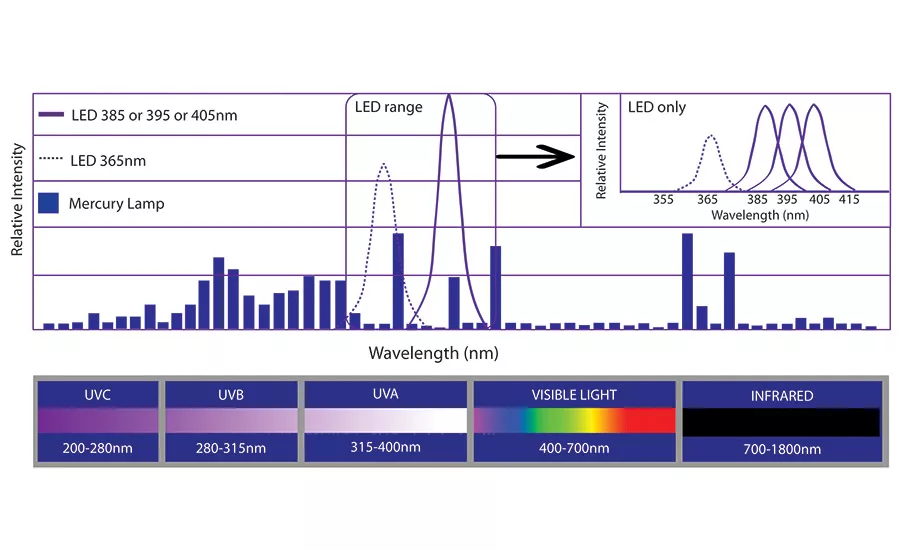

Figure 2. Comparison of the output of a various UV LED light sources with a typical mercury arc lamp.

Ultraviolet (UV) light-emitting diode (LED) curing technology has been adopted for adhesive bonding, sealant, and coating processes in factory assembly lines throughout the world. Adhesive chemistries that have been adapted to the UV function to enhance curing, handling, and user control include: acrylate/urethanes, cyanoacrylates, silicones, anaerobics, pressure-sensitive adhesives, film adhesives, and epoxies.

UV LED curing technology offers lower operating costs, long lifetime, enhanced system capabilities due to being a solid-state device, and environmental benefits associated with safer workplace environments. In addition, UV LED provides a low-temperature light source for small components that may be sensitive to heat.

Understanding UV Curing

UV curing is a photopolymerization process that uses UV energy to change a liquid to a solid. Upon absorption of the UV energy, the photoinitiator (PI) produces free radicals that initiate crosslinking with binders (monomers and oligomers) in a polymerization reaction to cure or solidify the coating or adhesive, usually in a few seconds (see Figure 1).

Industrial sources of UV energy have long included medium-pressure mercury arc and microwave-powered lamps, as well as the more recent LEDs. All three technologies are used to crosslink inks, coatings, and adhesives in a wide range of manufacturing processes. Both arc and microwave curing technologies rely on the vaporization of mercury within a sealed quartz tube containing an inert gas mixture. Mercury lamps require toxic mercury disposal and produce ozone gas that needs to be extracted by ventilation.

UV LEDs are solid-state semiconductors. UV LED generates UV energy by applying an electric current to a semiconductor device called a diode, causing it to emit UV energy. The specific materials in the diode determine the wavelengths of the output, which is typically in a very narrow band ± 10 nm. Figure 2 compares the output of various UV LED light sources with a typical mercury arc lamp. UV LED light sources are provided in single wavelength configurations, typically centered on a specific wavelength, ± 5 nm. This near-monochromatic distribution requires new chemical formulations to ensure proper curing of adhesives and coatings.

To achieve efficient and effective UV curing of an adhesive or coating, the formulator seeks to match the UV lamp spectral output with the absorption characteristics of the photoinitiators used in the formulation. Since current-generation UV LED emission wavelengths are strongest at 365 and 395 nm, photoinitiators and other formulation components should be selected to allow efficient excitation of the photoinitiators at those wavelengths.

Benefits

UV LED curing embraces many of the advantages of traditional UV curing for manufacturing processes, offering advanced capabilities beyond traditional mercury UV curing. First, UV LEDs do not generate any infrared output that is translated into heat. This is extremely important on manufacturing lines where the introduction of heat changes the chemical properties of the adhesive or coating. In these cases, heat can lead to material warping, lack of adhesion, and eventually scrap. UV LEDs are a “cool” light source; the only heat involved is due to UV energy being generated.

The second major improvement is process stability. Manufacturing companies need consistent, stable output. Traditional UV bulbs degrade over time, which means their UV output was not keep stable. UV LED provides stable UV output consistently over time, leading to better process control and stability.

Applications

UV LED curing technology is ideally suited for electronic assembly applications. The combination of high-energy UV LED sources with the appropriate adhesive enables increased productivity while also providing the ability to cure heat-sensitive materials. Many electronics manufacturers utilize UV LED curing in the production of products such as touchscreens, mobile phones, micro-speakers, and hard disk drives.

Adhesives used in medical applications such as syringes, catheters, IV delivery systems, endoscopes, and hearing aids often benefit from UV curing technology because it offers better uniformity, low heat, instant on/off capability, and long lifetime. UV LED curing solutions are also suited to ammunitions production for waterproofing, adhesive bonding, sealing, and coating. The UV LED curing of external ammunition sealants can make bullet pull strength more consistent, thereby improving performance and accuracy. Example ammunitions-related applications include: external ammunition sealing (i.e., waterproofing); igniter, fuse, and detonator UV sealing; specialty UV coatings and primers; blank ammunition sealing; shot shell crimp sealing; and tip color coding.

UV LED is also a curing solution for automotive coating applications because it provides near-instant curing of functional and decorative coatings. The lightweight materials used in today’s automobiles benefit from the low temperatures enabled by UV LED technology. The automotive industry utilizes UV LED curing solutions for forward lighting, tail lenses, interior and exterior trim components, and body panels.

Adhesive curing is utilized in industrial-grade bonding for a variety of materials. Industrial processes require products that can work in tough, sometimes harsh manufacturing environments. Industrial UV LED curing capabilities include solar panels, wood/plastic coatings, thin films, bottle processing, aviation, automobiles, and many others.

LED Lifetime and Reliability

If architected correctly, LED light sources can have exceptionally long lives. LED technology minimizes the heat load to the work surface, allowing for capability with heat-sensitive applications. The long lifetime, instant on/off control, and consistent UV output can improve process variation and control. Similar to the lighting industry, LED curing technology has been proven to be extremely reliable.

Even though LED technology is reliable, it is important to keep in mind that LED light sources are not created equally. Suppliers have significant architectural and implementation decisions that impact their products’ performance. The ideal end result will be a LED curing system with optimized LEDs, arrays, optics, and cooling for a specific application. Knowing how to characterize the performance allows the user to identify the best overall system to meet their needs.

While traditional mercury lamps may last up to 3,000 hours, properly managed LEDs will last over 50,000 hours. If the light sources are not cooled properly, however, they will have a much shorter lifetime and will be less reliable. Before choosing an LED supplier, ask for data on the lifetime of their lamps to make sure they are proven to be reliable.

Improving Manufacturing Processes

UV LED curing offers manufacturers higher yield rates and productivity due to a consistent and stable process with less damage to heat-sensitive components. In addition, UV LEDs are highly efficient, offering significant energy cost savings. They require very little space, making them easy to integrate into small spaces. Since UV LEDs produce no ozone emissions or hazardous waste concerns, they are an environmentally friendly and safe UV curing technology.

Adhesive and coating suppliers have formulations available for use with UV LED curing that are easy to handle and apply in the precision, high-speed processes that are so common in manufacturing. When looking to improve yield rates through higher productivity and reduced scrap, manufacturers should consider UV LED curing technology.

For additional information, visit www.phoseon.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!