Henkel Invests in MRO Startup Feelit

Adhesives and sealants improve the maintenance of production machinery and equipment around the globe.

Henkel Adhesive Technologies recently announced that it has strengthened its capabilities for maintenance, repair, and overhaul (MRO) solutions by investing in Feelit, a startup based in Haifa, Israel. Feelit has developed a sensor technology for predictive maintenance for various applications in manufacturing. With the investment, Henkel aims to further expand its MRO portfolio for its customer base in industrial markets.

“As part of our venturing activities we are looking for novel and scalable technologies complementing our existing portfolio in adhesives, sealants and functional coatings,” said Paolo Bavaj, head of Corporate Venturing for Adhesive Technologies. “We also focus on digital business models that help innovating our traditional businesses towards the increasing demands for novel and efficient industrial IoT solutions. The investment in Feelit perfectly fits to our business strategy and underlines the value of our long-standing engagement in Israel as a major global hub for materials and technology start-ups.”

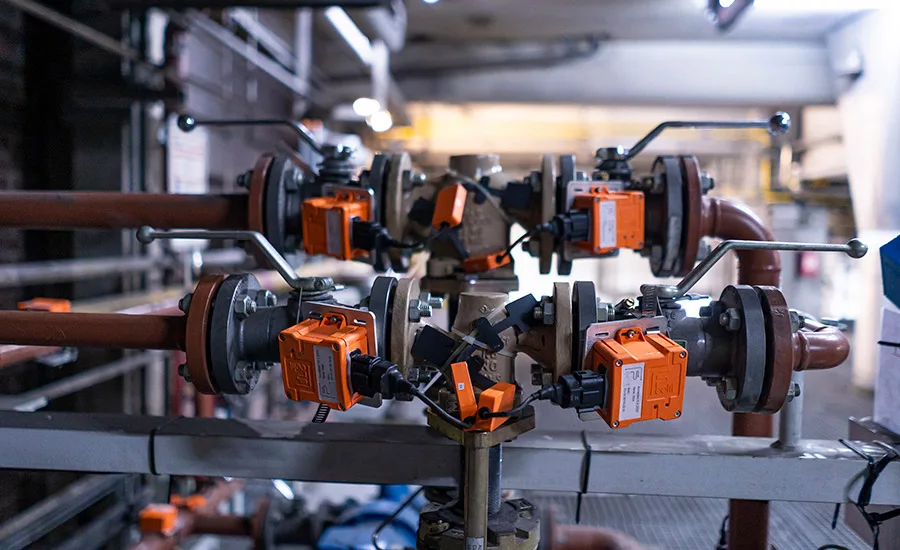

Henkel Adhesive Technologies provides MRO solutions in more than 800 different industry segments. Adhesives and sealants improve the maintenance of production machinery and equipment (e.g., in steel mills, car factories, mining equipment, or power turbines) around the globe. The products are designed to help manufacturers limit cost-intensive unplanned production line stops.

“As a global leader in the MRO markets we aim to implement Industry 4.0 solutions to expand our offering beyond materials,” said Michael Honné, head of MRO 4.0 at Henkel Adhesive Technologies. “The global market for predictive maintenance is expected to significantly grow over the next years as digital technologies have a huge potential to further reduce unplanned asset downtime and help preventing serious damages across multiple industries. Based on our leading market position and expertise of our Loctite portfolio we aim to leverage the technology of Feelit to develop innovative solutions providing additional value to our customers improving the day-to-day life of maintenance professionals.”

Founded in 2017, Feelit has reportedly developed a highly sensitive, flexible, printed nanomaterial sensor that is applicable on static and rotating machinery parts. This sensor can measure strain in ultra-high resolution, as well as other parameters such as temperature, vibration, and pressure. Based on an industrial IoT platform for real-time remote sensing of structural changes in mechanical assets, the system serves as an “electronic skin” that alerts on critical structural and operational anomalies in advance. With a 50-times higher sensitivity compared to current standard market applications, it allows condition monitoring and predictive maintenance of industrial assets like valves, pipes, and pumps, and prevents unplanned and cost-intense downtimes of machineries.

“We consider this a major leap in our ongoing financing and strategic efforts,” said Gady Konvalina, Feelit CEO. “Henkel is an exceptional strategic partner, and this collaboration is sure to yield significant opportunities for both companies. With Feelit’s growth potential and Henkel’s industry expertise and market reach, our unique nanotechnology will be able to benefit a broad relevant client base. The partnership has already begun opening up new opportunities in the oil and gas industry and working with Henkel’s MRO unit will help us to develop even more verticals and applications.”

For more information, visit www.henkel.com and http://feelit.tech.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!