The Future of Formulating Adhesives, Sealants, and Coatings

While formulating in the future won’t look drastically different from today, it will work much better.

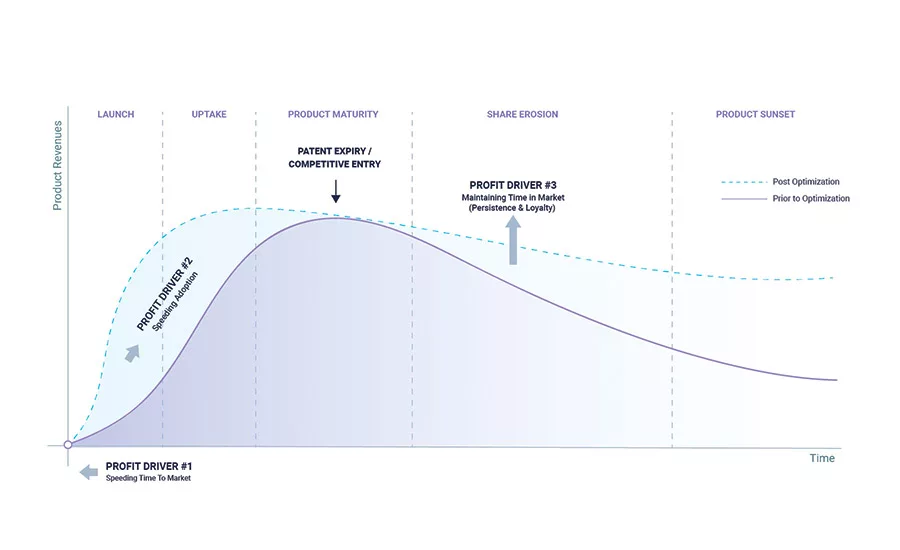

Figure 1. Three main profit drivers for product development.

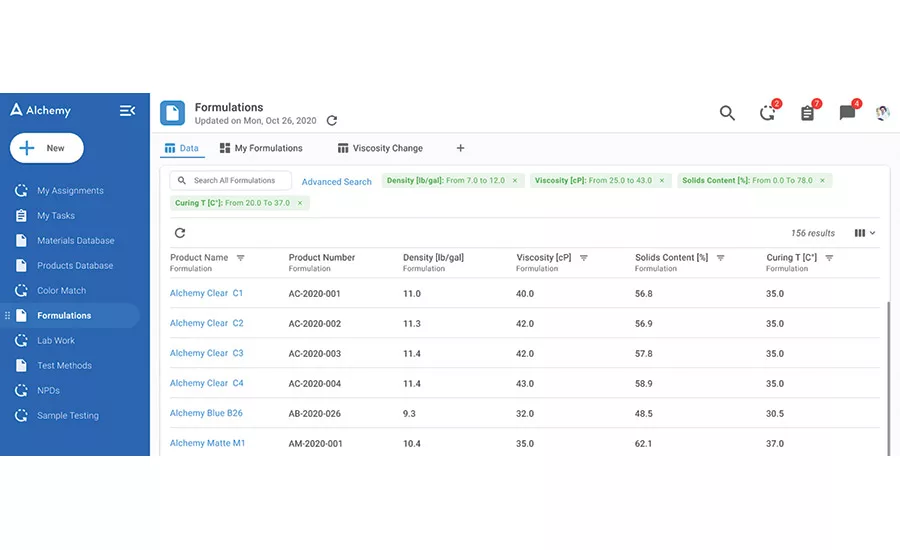

Figure 2. Finding and leveraging detailed project information at the property level of formulations is possible with proper tooling.

Chemical and materials companies have three mandates that, if done well, can ensure great business results for decades to come (see Figure 1). They must:

- Launch novel products faster than their competitors

- Drive rapid product adoption in the market

- Maintain customer loyalty to those products over time to offset the sunk cost of creating and servicing them

Sounds easy enough, right? If only it were as simple as the wave of a magic wand. Chemical and materials industry leaders are facing a challenge unknown to previous generations—and no, it isn’t digitalization (well, not directly at least). If not digitalization, the de facto nightmare/panacea for the industry, what could this issue be?

The challenge: Customer demand is shifting faster than ever before. In today’s always-on world, brands are one sensational YouTube ad served on your smartphone away from you ditching their goods and moving to the competition.

This ever-shifting landscape of customer demand has serious, often irreversible impacts on the materials world. While the average consumer may not have the slightest clue about the effects their preferences for an extra-strong iPhone screen, electrically powered Tesla, or mineral-infused Smart Water have on the materials value chain, chemical and materials company executives lose sleep pondering ways to keep pace with—or dare I say outpace—these seismic shifts in consumer preference.

Traditional Lab Practices

Let’s ponder why it is so hard for labs to answer questions like:

- Where are all completed projects from the past six months with a peak normal force between -10.30 N and -7.97 N?

- What experimental materials have we developed in the past two years with melting points between 120-160˚C?

- If we exclude our Ziegler-Natta polymerization route products, how many experimental materials have we commercialized this year?

- How many APAO-containing formulations received affirmative feedback from customers?

These questions are hard to answer because they are cross-functional, often transnational, and, almost always, have bits and pieces of the answer distributed across many places within the organization. The most common locations include the formulator’s beloved Excel file, management’s go-to LAN folder, and the C-suite’s treasured ERP reporting.

Little software industry ingenuity has targeted the lab to date, but chemistry is no longer a game played only with pipettes and Erlenmeyer flasks. Lab staff and their leadership deserve 21st century tools. The role of the chemist in recent decades has evolved into an interdisciplinary function that relies just as heavily on the use of computers and software as bending molecules at the bench.

This trend will continue in the future, making significant computer skills a prerequisite for such roles in the not-so-distant future. However, Microsoft Excel is not designed for chemists, LAN folder structures are not designed for lab projects, and email is not designed for sharing real-time updates.

Insightful Digital Tools

The future of formulating doesn’t look that drastically different from the formulating of today. What will differ more than anything on a go-forward basis is that data debt will have a greater negative impact on a firm’s ability to go to market effectively.

By contrast, chemists—and the organizations they support—will be able to leverage an ever-growing array of insights developed in their labs at the click of a button, so they don’t start from scratch. Chemists will continue to have the Excel-like flexibility they love, only without the annoying and time-consuming data wrangling they hate. Side-by-side comparisons and modifications of multiple formulations will still happen, but the results will be archived in a way that is searchable, reusable, and presentable. While lab techs will still be served work instructions, they will have those how-tos delivered alongside material and formulation properties that help them gain compounding leverage from their work over time.

At the same time, firms in this space will continue to groom talent who are, for better or worse, more familiar with and more appreciative of digital tools. Combining these two forces will create a world in which readily available legacy data insight can drive measurable top-line revenue growth and bottom-line cost savings.

Truth be told, this isn’t science fiction. Early adopter firms across the globe, from Texas to Australia, are reaping these benefits today. Some launch products faster, others marry technical inputs with business data to create holistic views of their business, and still others simply manage their day-to-day operations more efficiently. This multi-functionality may be the most unique insight about what the future holds for formulation-focused organizations: Software can augment your unique way of working cross-functionally to measurably speed the commercialization of chemistry.

For more information, email marketing@alchemy.cloud or visit www.alchemy.cloud.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!