EPIC RESINS: Additive Manufacturing Capabilities

The versatile 3D printing units can be used in numerous applications.

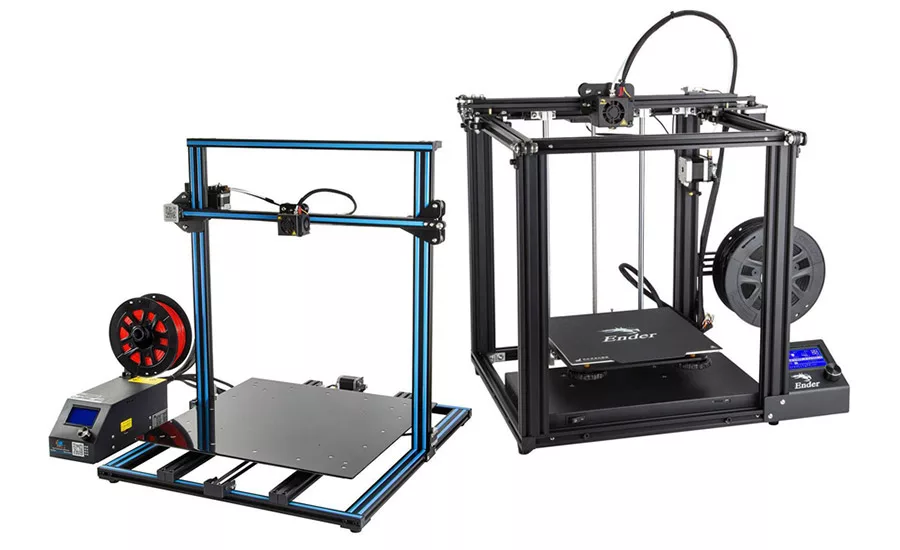

Epic Resins recently announced the addition of two 3D printers to its laboratory. According to the company, these units will be used to help customers innovate faster and more efficiently by taking time out of the testing or development stage.

The addition of the Creality CR-10 S5 and Creality Ender 5 Plus 3D printers will reportedly enable Epic Resins to help customers save time and money by leveraging the benefit of quickly producing custom enclosures and mold forms in Epic Resins’ laboratory. This added resource also allows Epic Resins to accurately custom print molds, jigs, forms, and other tools in-house to exact specifications.

The versatile 3D printing units can be used in numerous applications, including complicated casting needs, enclosures for a variety of industries, difficult molds, custom jigs, and fast turnaround testing. Epic Resins reports that the 3D printers will benefit its customer partners by:

- Removing the cost and time involved with shipping materials

- Rapidly prototyping objects and adjusting until tight dimensional tolerances are met

- Partnering in the development process by printing test pieces to match their design

- Adding the ability to create testing pieces for new product development

Learn more at www.epicresins.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!