Home » Keywords: » additive manufacturing

Items Tagged with 'additive manufacturing'

ARTICLES

Case Study

3D Printing Evolves to Deliver Value Beyond Business

3D printing technology has led to meaningful change across industries, but we’re only starting to see how it can help create change in communities.

May 13, 2022

PPG Produces 3D-Printed Ramp Seals for Lockheed Martin C-130J Super Hercules

The ramp seals are PPG’s first commercial sale of 3D-printed components.

December 2, 2021

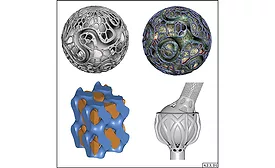

SCOTT BADER: Additive Manufacturing Resins

The new resins are available to both individual consumers and businesses.

November 24, 2021

RadTech and NIST Form Photopolymer Additive Manufacturing Alliance

The alliance will convene a three-part virtual workshop that builds on the Photopolymer Additive Manufacturing Roadmap developed by NIST and RadTech in 2019.

October 15, 2021

Top 5 News that Sticks

DL Chemical’s Acquisition of Kraton Leads the News

Last week, readers were most drawn to the planned acquisition of Kraton by DL Chemical.

October 4, 2021

EPIC RESINS: Additive Manufacturing Capabilities

The versatile 3D printing units can be used in numerous applications.

September 30, 2021

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1653417027&width=275)