Case Study

3D Printing Evolves to Deliver Value Beyond Business

3D printing technology has led to meaningful change across industries, but we’re only starting to see how it can help create change in communities.

.webp?t=1653417027)

Additive manufacturing/3D printing has grown into a $14 billion industry since its inception, according to McKinsey, and the market’s annual growth rate is 22%.1 Many can agree on the potential 3D printing has when it comes to innovation and being able to create prototypes and items with minimal material use, but its value is extending beyond that original purpose.

For example, in Austin, Texas, a technology company is using 3D printing to address the housing crisis.2 In addition, at the University of Virginia, 3D printing is being used to generate better tumor models to support cancer research. 3D printing technology has led to meaningful change across industries, but we’re only starting to see how it can help create change in communities.

Best Foot Forward

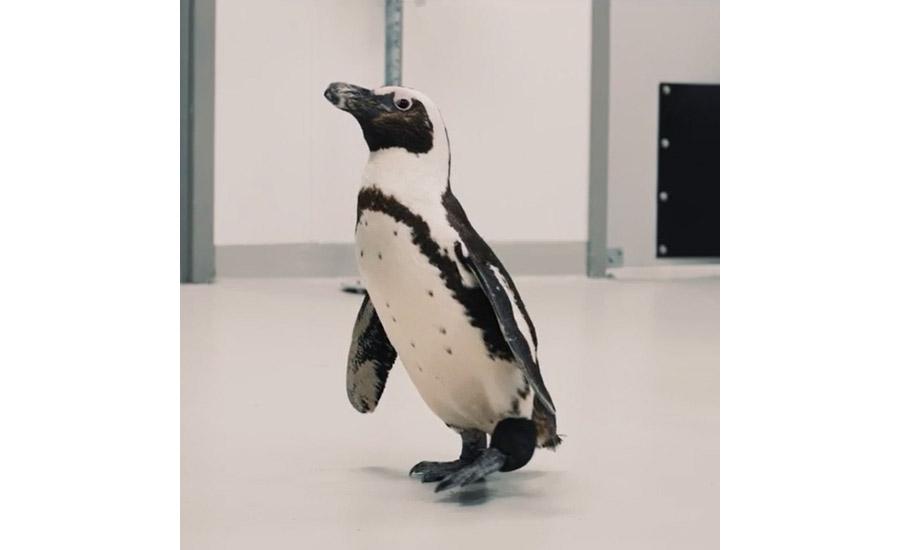

Purps, an endangered African penguin living in a colony at the Mystic Aquarium in Mystic, Ct., injured her ankle and needed support to enhance her mobility and improve her quality of life. ACT 3D Equipment and Services, a partner of Henkel’s LOCTITE brand, had provided an original boot that required frequent replacement.

“The original boot was successful in improving Purps’ gait, but we found that it needed to be replaced often due to wear and tear,” said Emily Turcan, Act 3D applications engineer. “We knew the boot needed to be reprinted in a more durable material such that it could withstand the environmental aspects of Purps’ everyday life.”

Act 3D reached out to Henkel’s LOCTITE team for support and, together with local middle school students and other community partners, created an enhanced boot for Purps so she could continue to live an active life. The team used the LOCTITE brand’s elastomeric resin, which includes high-performance mechanical properties that contribute to the durability, tear strength, and long-term stability of Purps’ boot.

Purps the penguin sports her elastomeric resin-based, 3D-printed boot.

Advancing Telehealth Capabilities

Interest in telehealth has significantly increased due to the COVID-19 pandemic, with McKinsey estimating 3x more investment in virtual care and digital health in 2020.3 This substantial growth led the Henkel team to partner with WeMed, a French start-up that wanted to quickly respond to the accelerating demand.

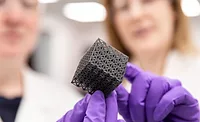

WeMed designed a connected SKOP stethoscope to support teleconsulting and remote monitoring. The stethoscope uses a biomimetic design based on the human ear to maximize performance. Due to the specific geometry of the SKOP design, however, it can only be efficiently executed through additive manufacturing.

The SKOP stethoscope’s complex geometry relies on 3D printing.

In collaboration with WeMed, Third, and Nexa3D, Henkel provided a customized material in less than a month, enabling a faster time to market. With Nexa3D printers, Third’s manufacturing expertise, and LOCTITE’s customized material, the team was able to successfully bring a more cost-effective and efficient stethoscope to full-scale production and meet the needs of thousands of patients. The stethoscope has been tested and embraced as a device of choice by cardiologists, pulmonologists, general practitioners, emergency physicians, and nurses.

Sustainable Developments

3D printing is also part of Henkel’s sustainability efforts, the overall goal of which is to triple the value created through business activities in relation to the company’s environmental footprint by 2030. Through a partnership with TerraCycle to help reduce waste, Henkel became the first organization worldwide to offer a recycling solution for anaerobic and light-cure adhesive packaging.

Henkel provides customers that have 3D printing operations with a recycling box where used containers of UV-curable 3D resins and cyanoacrylate-based adhesives are placed and later recycled by TerraCycle. This year, the program was able to collect enough recycled packaging to begin exploring opportunities to upcycle the waste and create something new.

For more information, visit www.henkel-northamerica.com. Henkel’s partners in these projects can be found online at https://3dp-materials.com, https://en.wemed.fr, https://nexa3d.com, and www.terracycle.com/en-us/.

Note: Images courtesy of Henkel.

References

- J. Bromberger, J. Ilg, and A.M. Miranda, “The mainstreaming of additive manufacturing,” McKinsey & Co., March 15, 2022, https://www.mckinsey.com/business-functions/operations/our-insights/the-mainstreaming-of-additive-manufacturing.

- R. Hertzberg, “How 3D-printed homes can help fix the housing crisis in America,” The Hill, July 16, 2021, https://thehill.com/changing-america/video/563493-how-3d-printed-homes-can-help-fix-the-housing-crisis-in-america.

- O. Bestsennyy, G. Gilbert, A. Harris, and J. Rost, “Telehealth: A quarter-trillion-dollar post-COVID-19 reality?,” McKinsey & Co., July 9, 2021, https://www.mckinsey.com/industries/healthcare-systems-and-services/our-insights/telehealth-a-quarter-trillion-dollar-post-covid-19-reality.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!