Optimizing Hydrogenated Styrenic Block Copolymers for Adhesives and Sealants

Highly compatible with additives, specialty hydrogenated styrenic block copolymers enable product and process optimization for adhesives, sealants, and coatings formulators.

Hydrogenated styrenic block copolymers (HSBCs) are suitable for elastomeric adhesive applications. They are used in hot-melt adhesives (HMAs) and solvent-based adhesives, as well as in plastics modification for consumer and industrial applications. These block copolymers have good physical properties and are compatible with additives such as tackifiers and processing oils.

Since HSBCs have good resistance to degradation under UV light exposure, they have good color stability and can withstand exposure to harsh outdoor environments. HSBCs also have low odor, good physical properties, and balanced adhesion performance on various substrate surfaces (e.g., glass, wood, metals, and nonwovens).

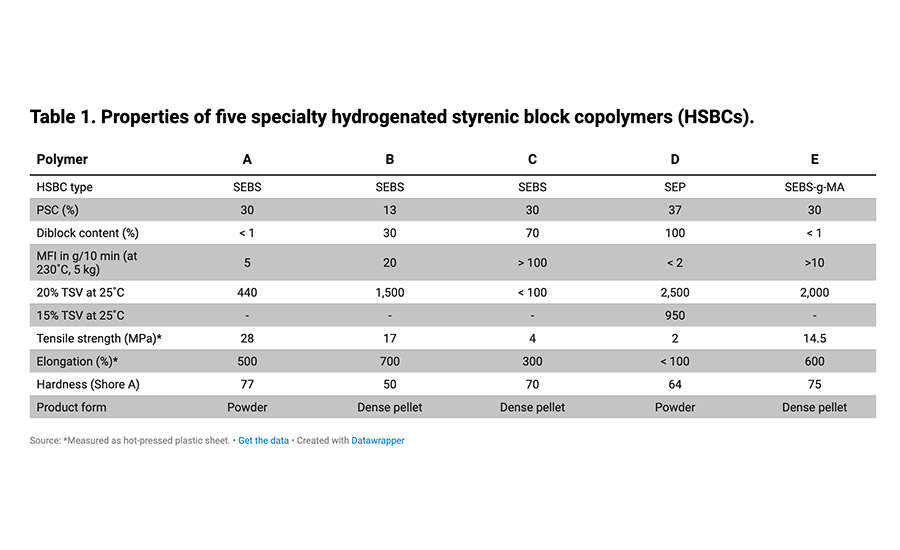

Specialty HSBC grades have good compatibility with additives. They are easily combined with other materials and can be used in many applications. Table 1 details key properties of several HSBC grades.

HSBC A is a low-molecular-weight linear triblock copolymer with an intermediate level of styrene content (30%). The polymer provides balanced mechanical properties and good compatibility with polyolefins such as PP, PE, and EVA. Commonly used in hygiene applications, it is also widely used in coating and sealant applications due to its high strength.

HSBC B has a lower styrene content of 13% and a 30% diblock content, making it softer and more elastic than conventional HSBC grades. HSBC B is a high-flow polymer for adhesives, coatings, sealants, and polymer impact modification.

HSBC C has a much higher diblock content (70%) and provides excellent flow in adhesive, sealant, and coating applications. It also has better adhesive performance, particularly its wetting property. It can be used for hygiene diaper applications that require high-speed production and lower processing temperatures.

HSBC D is a 100% pure diblock SEP structure designed to provide cohesion performance, special thixotropic characteristics to increase sag resistance, and enhanced shear-thinning function to many products such as fiber optical cable filling compounds, cosmetic thickeners, sealants, coatings, and energy damping.

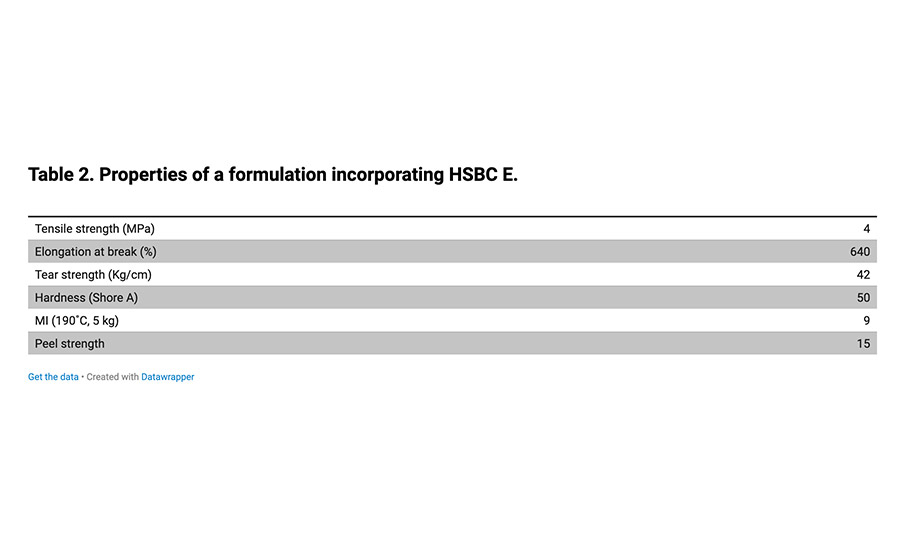

HSBC E is a maleic anhydride-grafted SEBS with increased polarity for over-molding compounds and impact modifiers. The effective 1.5% MA grafting ratio results in excellent adhesion to metal or polar substrates, as well as good compatibility with engineering plastics to improve low-temperature impact strength.

HSBCs for Oil Gel Applications

Styrenic block copolymers (SBCs) have a two-phase structure composed of hard endblocks and softer rubber midblocks. The rubber blocks of HSBCs are highly compatible with mineral oils. When a triblock HSBC is added to oils at sufficient quantities, the triblock structure causes the oils to solidify. This results in flexible, strong, solid oil gels with adhesive properties and tackiness. The midblock segments provide elasticity. The diblock EB polymer results in balanced cohesive and adhesive properties.

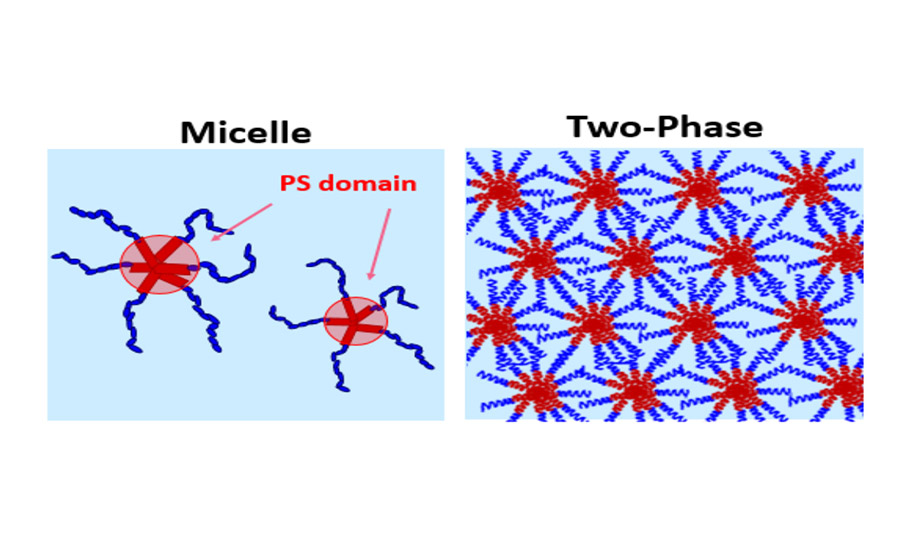

HSBCs with ethylene/propylene (EP) structures, such as HSBC D, are used at low concentration levels as thickeners for paraffinic oils to impart shear-thinning behavior. It can also be added at higher levels to create thixotropic greases. In this case, the polystyrene endblock segments with extended rubber arms form micelle-like domains to create the thixotropic properties (see Figure 1).

Figure 1. Polystyrene endblock segments with extended rubber arms form micelle-like domains to create thixotropic properties in thixotropic greases.

Figure 1. Polystyrene endblock segments with extended rubber arms form micelle-like domains to create thixotropic properties in thixotropic greases.

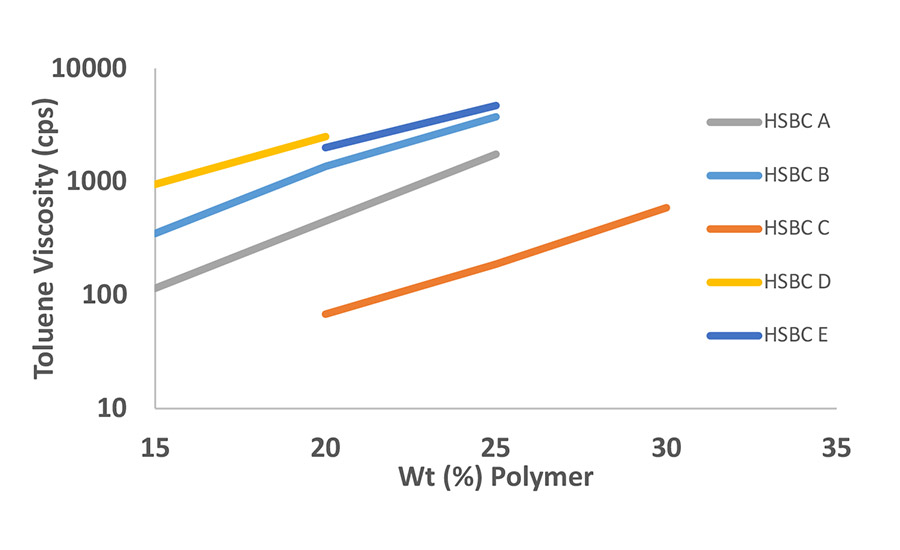

Toluene Solution Viscosity

Toluene solution viscosities at room temperature were measured for these polymers (see Figure 2). Compared to other grades, HSBC C has the lowest molecular weight and highest diblock content, making it the lowest in solution viscosity. The viscosity of HSBC A, which has no diblock, is about 10 times higher. HSBC B has even higher viscosity due to its higher molecular weight. Although HSBC D has a 100% pure diblock structure, the higher molecular weight counteracts the effect of the diblock content on viscosity.

Maleic anhydride-grafted HSBC E is formed using HSBC A as its base. After grafting, the viscosity of HSBC E noticeably increases due to increased polarity. The solution viscosity can be reduced with the addition of polar solvents such as isopropyl alcohol.

It is also important to note that maleic anhydride reacts with water to form an acid, which increases the toluene solution viscosity. Control of HSBC E’s moisture content before use will provide better processing and performance consistency.

Figure 2. Toluene solution viscosities at room temperature.

Figure 2. Toluene solution viscosities at room temperature.

Hot-Melt Adhesive Evaluation

Sustainability has become a major focus for many manufacturing companies. Low-molecular-weight HSBC grades can minimize processing heat and reduce energy costs. HSBC A is an SEBS triblock polymer with low molecular weight. Due to the pure triblock design of HSBC A, it has good elastic stretch and recovery, high softening point, and enhanced physical properties.

High-flow HSBC C further reduces viscosity and synergizes well with other polymers and additives, which enables easier processing by lowering shear and torque requirements. HSBC B, which has 13% polystyrene content and 30% diblock, has lower hardness and better flow than HSBC A.

As shown in Figure 3, HMA formulations made with different ratios of polymers were evaluated for pressure-sensitive adhesive performance. The data indicate that HMA made with HSBC C and some HSBC A has the highest softening point. HMA made by HSBC C with some HSBC B has high softening point, shear adhesion failure temperature (SAFT), and higher cohesive strength.

Figure 3. Results of hot-melt adhesive evaluations for formulations containing ratios of HSBCs A, B, and C

Figure 3. Results of hot-melt adhesive evaluations for formulations containing ratios of HSBCs A, B, and C

Sealant Application

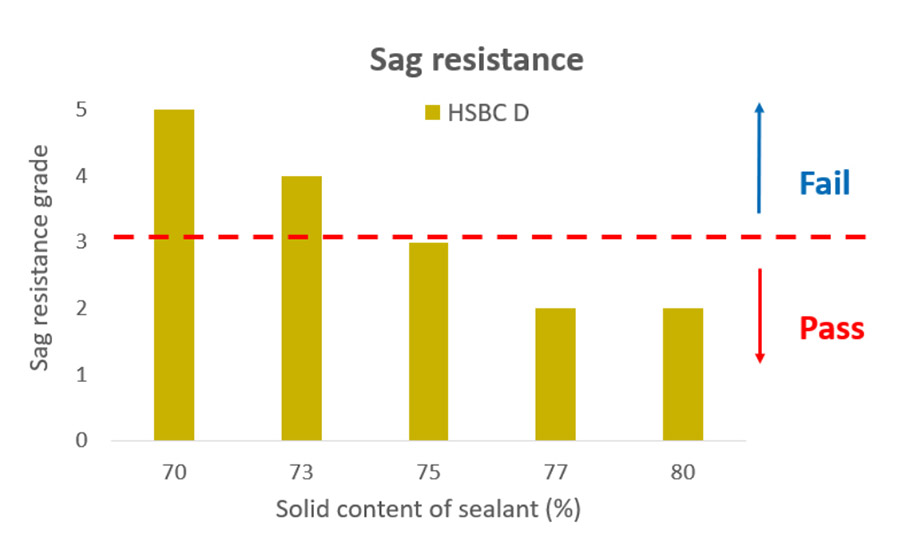

HSBC polymers such as HSBC A, B, and C are used in solvent-based sealant applications to generate strength and elastic recovery. However, most polymers have shear thinning behavior and flows under stress. HSBC D has a unique thixotropic characteristic to prevent the sealant from sagging.

In a series of experiments, a container was filled with a mixture of HSBC A and HSBC D with tackifier in toluene. The container was attached to a fixture vertically, and the sealant’s vertical flow distance was measured after 4 hrs at room temperature.

Figure 4. Impact of solid content on sag resistance.

Figure 4. Impact of solid content on sag resistance.

Sealants made with SEP have good sag resistance at higher total solid content. Compared to HSBC D, the addition of high-flow HSBC C can reduce sealant viscosity and allow smooth flow of sealants during application. HSBC C combined with HSBC A can also be used in solvent-based adhesives or rough-surface wood panel adhesives.

Non-Polar Substrate Adhesive and Plastics Modification

HSBC E can be used to enhance the adhesion of over-molding compounds on non-polar substrates. HSBC E provides good physical properties in TPU over-molding. It can also be used to modify engineering plastics to improve low temperature impact strength. The polarity helps to compatibilize polar and non-polar materials for polymer alloys, recycled products, and wood plastic composites.

It can also be used in adhesive, sealant, and coating formulations. Solvent-based adhesives are often used in multi-layer structures such as PE foam/metals/PP nonwovens. HSBC E can be used in such cases as a tie layer between plastics and metals to provide good adhesive strength and reasonable operation open time.

It can also be used in adhesive, sealant, and coating formulations. Solvent-based adhesives are often used in multi-layer structures such as PE foam/metals/PP nonwovens. HSBC E can be used in such cases as a tie layer between plastics and metals to provide good adhesive strength and reasonable operation open time.

Optimized Formulation

Advanced manufacturing technologies are required to produce high-performance SBC polymers with high precision. Several low/middle-molecular-weight HSBC products were studied for special adhesive, sealant, coating, and oil-gel formulations, as well as plastics modification. These products are highly compatible with polyolefins and allow product and process optimization for formulators. New polymers that provide solutions in sustainability and efficiency will be developed in the near future.

For more information, visit www.lcygroup.com.

Note: Opening image courtesy of janiecbros via E+ on Getty Images. All other images are courtesy of LCY.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=96&t=1633665740&width=96)