SHIN-ETSU SILICONES OF AMERICA, INC.: Conformal Coating for Printed Circuit Boards

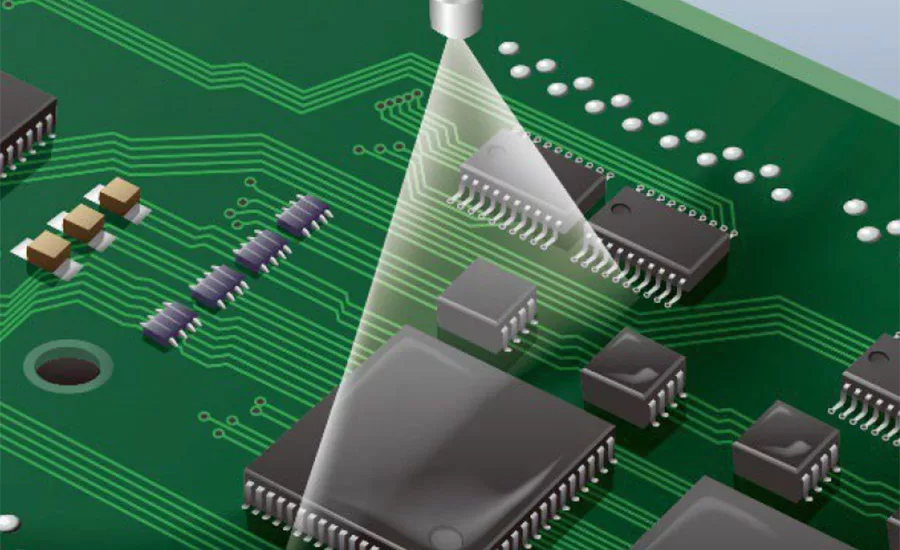

MR-COAT products are suitable for spraying, dipping, brushing, and flow coating of PCB/PWB applications. (Image courtesy of Shin-Etsu Silicones of America, Inc.)

Shin-Etsu Silicones of America, Inc. (SESA), a U.S. subsidiary of Japan-based Shin-Etsu Chemical Co. Ltd., has launched its MR-COAT-01F and 02F conformal coating series. According to the company, the line features high hardness coupled with extremely high elongation for better abrasion resistance and less stress on printed circuit board (PCB) components.

Today’s PCB systems and printed wiring board (PWB) applications experience extreme stress on their wire bonds and circuitry components that can significantly reduce their usage life. The MR-COAT products are hard resin-based, one-component systems that do not use toluene as a solvent, making them suitable for protective coating for rigid and flexible PCB and PWB system applications.

SES reports that the series offers significantly higher elongation than standard resin-based conformal coatings. Non-corrosive for general metals, they are suitable for spraying, dipping, brushing, and flow coating of PCB/PWB applications such as electronics, PCBs, and LED signs/lights.

Property benefits of both materials can reportedly be optimally matched for the best coating method required for the process while eliminating assembly steps and providing a much leaner process for production. Both products in the low-viscosity series are transparent, offer excellent electrical properties, are good for moisture-proof and waterproof coating on PCBs, and are a condensation cure (room temperature/alcohol type).

MR-COAT-01F features a viscosity of 70. This lower viscosity material is softer (55 Shore A), making it ideal when using a dipping tank process, and is also easier to spray. Notably, it features an elongation at break of 280 and a dielectric breakdown strength of 25 KV/mm.

MR-COAT-02F features a viscosity of 350. This higher viscosity material is harder (71 Shore A) but has a higher elongation than the softer 01F material. It features an elongation at break of 510 and a dielectric breakdown strength of 27 KV/mm.

SESA’s MR-COAT series both are tack free in approximately 5 min or less, so coated parts can be safely handled without the use of an oven or other extra curing process. This allows users to move on swiftly to other essential just-in-time processes.

“Shin-Etsu’s MR-COAT silicone conformal coating series provides end-users a resin-based system that has more abrasion resistance than elastomer systems, without the use as toluene as a solvent,” said Paul Alexander, national business manager-RTV/TIM. “The abrasion resistance is high for this coating which is vital for abrasive applications such as electric welding machines that get hosed down via power washers on trucks which can damage PCBs. Ultimately, MR-COAT will protect against these types of harsh exposure.”

Additional details are available at www.shinetsusilicones.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!