Taking a Resin Dispensing Process from Prototyping to Commercialization

Flexibility is needed in every step of a new adhesive or sealant product’s life cycle—from conceptualization to commercialization.

The current state of manufacturing is complicated to say the least, with supply chain issues involving raw materials and electrical components hitting several markets hard. Even with wide-ranging effort, there is a chance this will last at least to the end of 2022.

These issues push all levels of the manufacturing process to demand higher flexibility in every step of the life cycle of a new product—from conceptualization to commercialization—in order to achieve results. This flexibility can often bring the risk of cutting corners whenever possible, including but not limited to waiving the validation of the design for manufacturing or the rapid prototyping of sample products.

Generally speaking, the hand dispensing of resins in prototypes is not a complicated process. When possible, it is best to provide a degree of freedom and control for the technician, real-time correction of dispensing patterns, planned prototypes, and ample time (vs. a series production cycle time). It is also important to keep in mind that the properties of the dispensing materials may change as the product moves from the batch prototyping process to a continuously operating commercial process. Optimizing these factors will aid in the development of a transparent commercialization process, with straightforward resin dispensing and industrial dispensing equipment selection, all completed in an expedited timeframe.

Application Examples

Let us consider three different applications: dispensing of 2K thermal interface materials (TIM), potting with polyurethane (PU), and the application of a 1K room-temperature vulcanizing (RTV) adhesive.

- Prototype dispensing of 2K TIM—The operator loads a dispensing device or gun with the component or components, loads the mixing tube, and dispenses the paste in the required areas. The material is dispensed at an angle, over components, under components, between tight spaces, or on the side of critical points with no issues. The units are finished, and the mixer is discarded. The cartridges are then stored for further use.

- Prototype dispensing of PU—The operator mixes the two low-viscosity components by hand, pours some material in the housing, tilts the part in every direction to obtain better coverage, loads and snaps a populated printed circuit board (PCB) with vent holes, tops off with the rest of the material, and then snaps on the housing cover. This is an extreme example, but it represents real-life experience.

- Prototype dispensing of 1K RTV—The operator loads a single-component cartridge of material into a caulk gun, cuts the tip, applies the material on an angle, seals the components, applies material to a perimeter groove, seals a cover on top, wipes the tip after finishing, and saves the cartridge for future use.

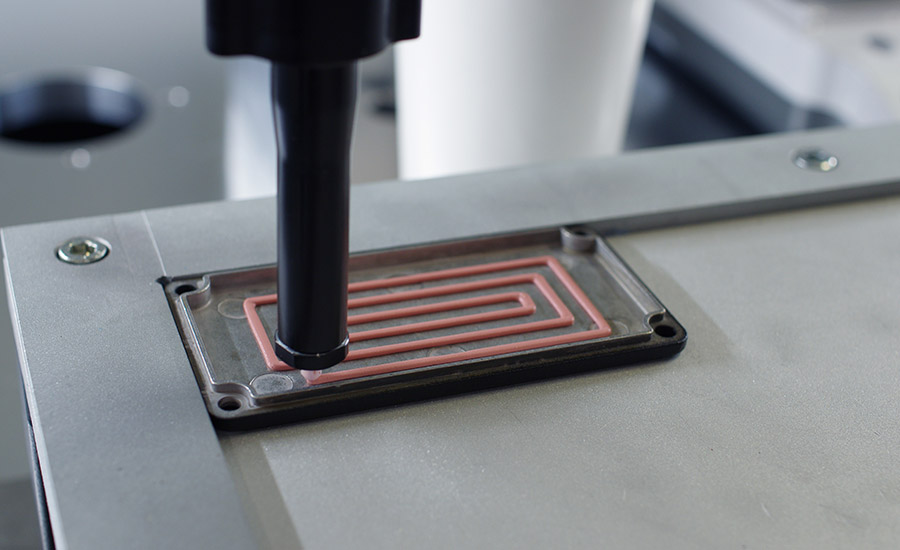

Dispensing a thermal interface material (TIM).

When prototyping, the goal is often to finish the parts as soon as possible because of the battery of tests that need to be performed afterward by both the manufacturer and the end customer. These tests, which regularly take weeks to finish, are the validation to confirm that each of the mechanical, electrical, and functional purposes of the part are up to the requirements of the end customer. Thus, little attention is paid to the actual extraction of the process parameters and methods for each individual manufacturing application, which is essential for the commercialization of the product.

The validation of the product is the final purpose of the prototypes, and stressing the design process can be challenging. However, as previously mentioned, flexibility is now key for successful product launches in a timely manner. As a result, product manufacturers should rely now more than ever on materials and equipment supplier experts. Taking advantage of suppliers’ expertise can reduce valuable weeks in the gap that exists between design and production, and data can be extracted in parallel when the prototyping is being carried out.

Taking into account the examples detailed previously, some of the main questions that equipment suppliers would initially ask when moving forward with commercialization would include: What material is to be dispensed? How much material is to be dispensed? What is the flow rate of the material? In which container will the material be presented? Does the product need to be preheated? What are the dispensing patterns?

Many factors need to be evaluated during the commercialization process.

These are only initial questions that unfortunately are not enough for a manufacturing equipment proposal to be actually generated, much less the definition of the type of pumps, mixing technology, material preparation system, and manufacturing concept. However, if the prototyping could be conducted together with the material and equipment suppliers, the build of the prototypes would not only provide enough data to develop the proposal but also will have been constructed with the appropriate scalable technology to better show the end product and remove the uncertainty of the method and equipment used to build the prototypes.

When prototyping is carried out in a dispensing technology center, key features are defined and controls are configured according to the product and material specification. The proposal can include such defined controls as pressure monitoring, dispensing needle checks and cleaning, container filling, mixing rotation speed control, continuous dispensing speeds, flow rates, container level monitoring, weight and ratio control, pot life monitoring with automatic purging, temperature regulation, and more.

Beware “Standard” Solutions

Each application is unique in its nature. Even when a “standard” solution may be an attractive choice, it might not be the best option, given that each individual new product demands an analysis for manufacturability.

Even when a type and brand of material is applied to different products, it is possible to transfer only some parameters to the new application without much reconfiguration (particularly those that refer to the mixing, dispensing, and maintaining of the material’s integrity). Process trials should be carried out in a technology center to confirm that such parameters are still functional and no changes have occurred in the material’s chemistry.

Process trials can help confirm that various parameters are still functional and no changes have occurred in the material’s chemistry.

As an example, one company had a particularly difficult situation regarding the contrast between the dispensed material and the housing. The company was experiencing a lot of inconsistencies in the dispensing of an adhesive. The continuity of the adhesive bead was often broken, and the vision system was unable to identify these inconsistencies because of the contrast issues.

Even though the company had determined the necessary parameters for the application, a process trial was conducted. During the trial, one of the engineers in the technology center did a light test to try to improve the visibility of the dispensed material. The engineer mistakenly took out a black light, however, making the resin glow with a green hue. It turns out that this luminescence is reliable due to the chemical reaction between the two components. As a result, a potential 3D profiling device to detect the material turned into a more simple and less-expensive vision system.

As a final note, it is important to remember that the manufacturing market is ever changing. As new technologies emerge, manufacturing facilities and material and equipment suppliers must establish partnerships from the earliest stages of a new product launch in order to maintain the competitiveness that the various technologies have to offer.

For more information, contact the author at alex.ortega@bdtronic.com or visit www.bdtronic.com.

Photos courtesy of bdtronic.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!