Mixed, Not Stirred: Achieving Bubble-Free Adhesives and Sealants

When mixing adhesives and sealants, it is important to work as homogeneously as possible and without bubbles to ensure optimum adhesion and a full seal.

Hauschild SpeedMixer® in a robotic system from Labman Automation UK.

Hauschild Engineering reports that its SpeedMixer® has the ability to mix multi-material compounds in just a few minutes and without any air bubbles. Materials created with this mixer are used in almost all industries, including rubbers, paints, plastics, batteries, and—last but not least—adhesives and sealants. Inadequate mixing is particularly critical with adhesives and sealants, because air does not stick or seal.

The use of adhesives and sealants is increasingly replacing conventional joining techniques. When mixing, it is important to work as homogeneously as possible and without bubbles to ensure optimum adhesion and a full seal.

Air bubbles form when stirring tools are used. The tools must also be cleaned extensively after each batch to prevent contamination. In addition, the mixing process often takes a long time and thus ties up unnecessary capacities. Professional centrifugal mixers deliver air-bubble-free, homogeneous, reproducible results completely without stirring tools.

Use of Centrifugal Forces

The key to success is dual asymmetric centrifuge (DAC) technology. The special feature of this mixing principle is the double rotation of the mixing cup. The combination of centrifugal forces acting in different planes enables an extremely efficient mixing process, which is characterized by a homogeneous result without the use of stirring tools.

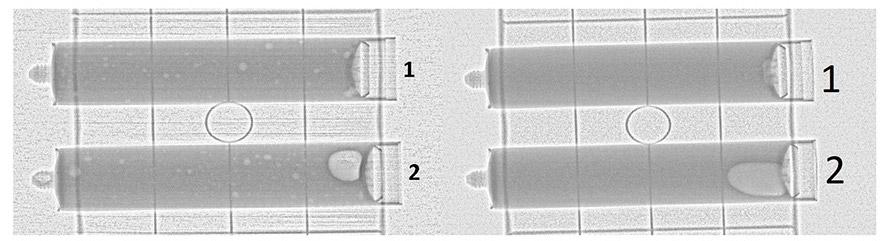

Figure 1. Silicone adhesive before (left) and after the mixing process. (Image courtesy of Lohnpack GmbH, www.lohnpack.info.)

Almost 100% degassing is carried out during the mixing process. Even the smallest micro-bubbles are removed, and there is no need for an additional degassing cycle.

For complete degassing, the Hauschild SpeedMixer® is available with vacuum technology. Programmable cycles ensure identical, reproducible mixing of each batch and lead to a considerable acceleration of the development process.

The Hauschild SpeedMixer® mixes without stirring tools in disposable cups, which eliminates the need for cleaning and the additional use of chemicals. The dimensions of the mixing cups and mixing buckets range from a few grams to 10 kg and a few milliliters to 16 liters of nominal capacity, depending on the size of the batch.

The applications of this centrifugal mixer are as diverse as the product world. It is possible to mix different liquids and pastes, pastes with powders, powders with powders, and other combinations of liquids and powders. Materials with different chemical and physical properties can also be mixed to form new sealants and adhesives, rubbers, plastics, and other products.

Data Exchange and Robotics

If the laboratory mixing device is to be integrated into an automated process, Hauschild Engineering designs suitable robotic devices in close customer dialog. Accessories such as mixing bowls, holders, cartridges, or the LeverPress filling system are also supplied according to customer specifications and applications.

Hauschild SpeedMixer® in a robotic system from Labman Automation UK.

Process automation is supported in various ways. The new SMART DAC generation offers the possibility of integrating various sensors such as temperature and humidity, smoke, fire detection, and dissolved gases, optimizing safety when mixing hazardous materials.

Full Integration

The mixers are programmable; up to 500 programs/recipes can be executed automatically, and up to 12 steps/programs and multi-program sequence functions can be selected. Acceleration and deceleration of the mixing vessel is also separately programmable for each step. Work in larger laboratories with many employees is supported by the multi-user function with different access rights.

Work in larger laboratories with many employees is supported by the multi-user function with different access rights.

For further processing of the mixing material in robotic systems, it is also important that the mixing container comes to a standstill at exactly the same point at the end of the mixing process (e.g., so that a robot gripper arm can remove it). According to Hauschild, the robotic version vacuum of the SpeedMixer® SMART DAC is the first of its kind worldwide that reliably achieves this.

For more information, visit www.hauschild-speedmixer.com.

Photos courtesy of Hauschild Engineering, unless otherwise noted.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!