How Edge Sealants Can Improve Performance in Crystalline Modules

Emerging trends in photovoltaic (PV) module development have exposed a need for higher levels of moisture protection throughout the PV marketplace—where edge sealant technology can make an impact.

Large-scale solar power investors are increasingly looking for new levels of quality assurance to help them be confident their investments will pay off. Bankability is a critical metric. It demonstrates market confidence in your products and is increasingly a measure by which purchasers of PV modules are basing their decisions. Modules that deliver longevity, reliability, and durability can prove to investors and customers that it’s worth placing their trust in a company and its products.

In this article, we’ll explore how and why moisture protection technologies — specifically, desiccated polyisobutylene/butyl (PIB) edge sealants — can help create greater reliability than modules without such protection. While it is typically assumed that crystalline silicon (c-Si) panels are not sensitive to moisture ingress over the long term, testing performed by Quanex’s technical teams shows that this common wisdom is not necessarily true. Our methods have demonstrated edge sealants’ ability to provide high levels of moisture protection beyond current design methods in c-Si panels, helping to reduce moisture-related power degradation and achieve more power output over a longer lifetime.

Why Emerging Solar Technologies Can Benefit from Moisture Protection

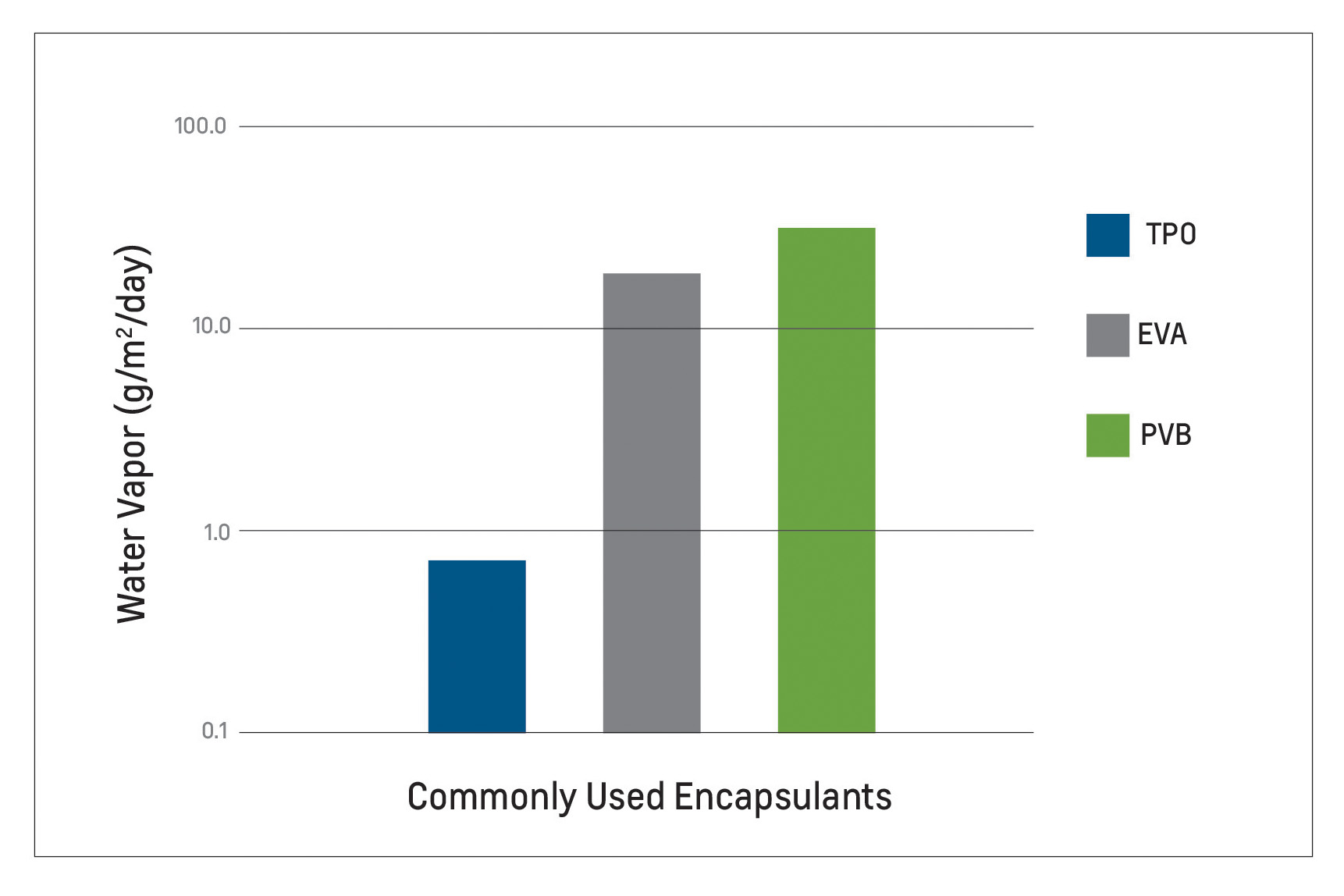

Several emerging encapsulant technologies have shown promise at improving overall performance in c-Si modules compared with more traditional ethylene vinyl acetate (EVA) encapsulants. Consider that EVA has the potential to form acid that can sap panels of their power due to the corrosiveness of the acid as a result of moisture intrusion over time. This drawback has not stopped EVA from becoming a popular encapsulant of choice, but some manufacturers have sought alternatives. Thermoplastic polyolefin (TPO) is one of those alternatives, which has demonstrated higher potential to resist moisture ingress versus EVA (see Figure 1).

*Click the image for greater detail

Figure 1: Quanex laboratory results using MOCON PERMATRAN-W equipment, Method ASTM F1249, normalized 1.52 mm film at 37.8 °C, 100% RH. Various material suppliers.

Polyvinyl butyral (PVB) encapsulants are another alternative to EVA. Both TPO and PVB may have benefits compared to EVA, however, these alternative encapsulants can be considerably more expensive and more difficult to handle during the assembly process. Additionally, corrosion of silver interconnects from moisture can still occur.

Other new alternative cell constructions, such as perovskite materials (PSC) and heterojunction (HTJ) technologies, have shown potential for higher module efficiency. But these technologies have shown even greater moisture sensitivity — therefore requiring enhanced levels of moisture protection.

Taken collectively, these conditions point to a true market need for higher levels of moisture protection throughout the PV marketplace. Proven, available technology exists that has long helped protect thin-film PV modules against moisture intrusion.

Demonstrating How Edge Sealants Deliver Protection

Research conducted by Quanex has demonstrated edge sealants’ ability to provide high levels of moisture protection in c-Si modules, helping to reduce moisture-related power degradation and achieve more power output over a longer time horizon. By utilizing edge sealants in this way, module manufacturers can continue the use of field-proven EVA c-Si modules without the expense and handling issues of non-EVA encapsulants, while maintaining higher levels of energy output over a long and useful life. Furthermore, our work indicates that edge sealants can help boost the longevity of all types of modules.

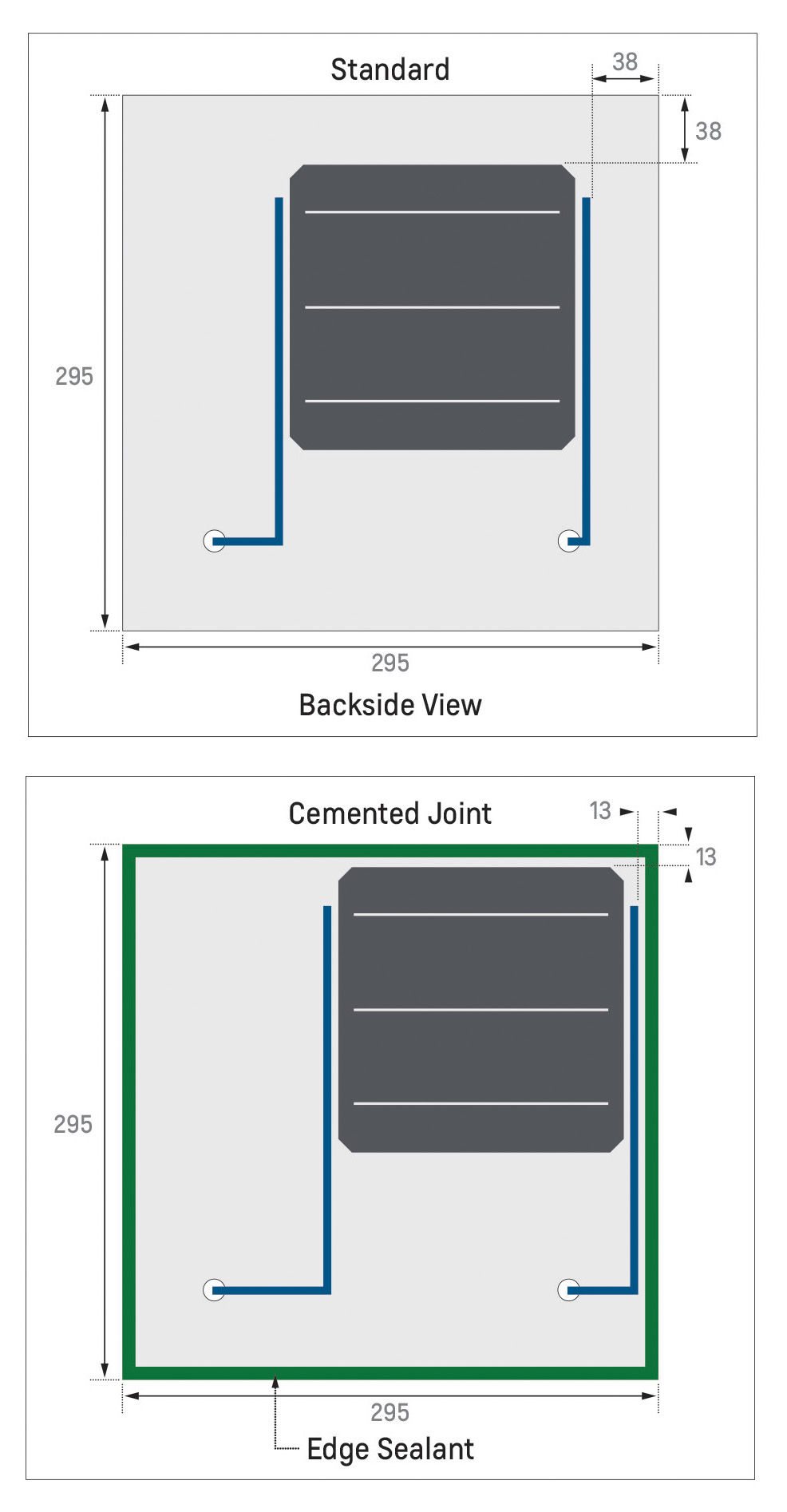

To demonstrate the protective benefits of edge sealants, we sought to compare typical c-Si modules using EVA encapsulants with test units using EVA and our SolarGain Edge Sealant, capable of acting as a cemented joint, as permissible by the International Electrotechnical Commission (IEC) specification 61730-1, section 5.6.4. (See Figure 2). This specification allows the use of solid insulation to isolate the electricity in a PV module. Depending on the design, the edge sealant can qualify as solid insulation or a “cemented joint” while providing enhanced levels of moisture protection for EVA encapsulants. By taking this approach, the internal live parts of the module are permitted to be significantly closer to the edge of glass than without solid insulation. Our team reduced the cell placement from 38 mm, typical in 60- and 72-cell 1500V modules, to 13 mm from the edge of the glass. This included a tape width of 10 mm, meeting distance through insulation (DTI) requirements.

*Click the image for greater detail

Figure 2: Our test unit featuring the cemented joint edge sealant design (bottom) mimics the corner cell of a full-size 1500V module to meet distance through insulation (DTI) requirements.

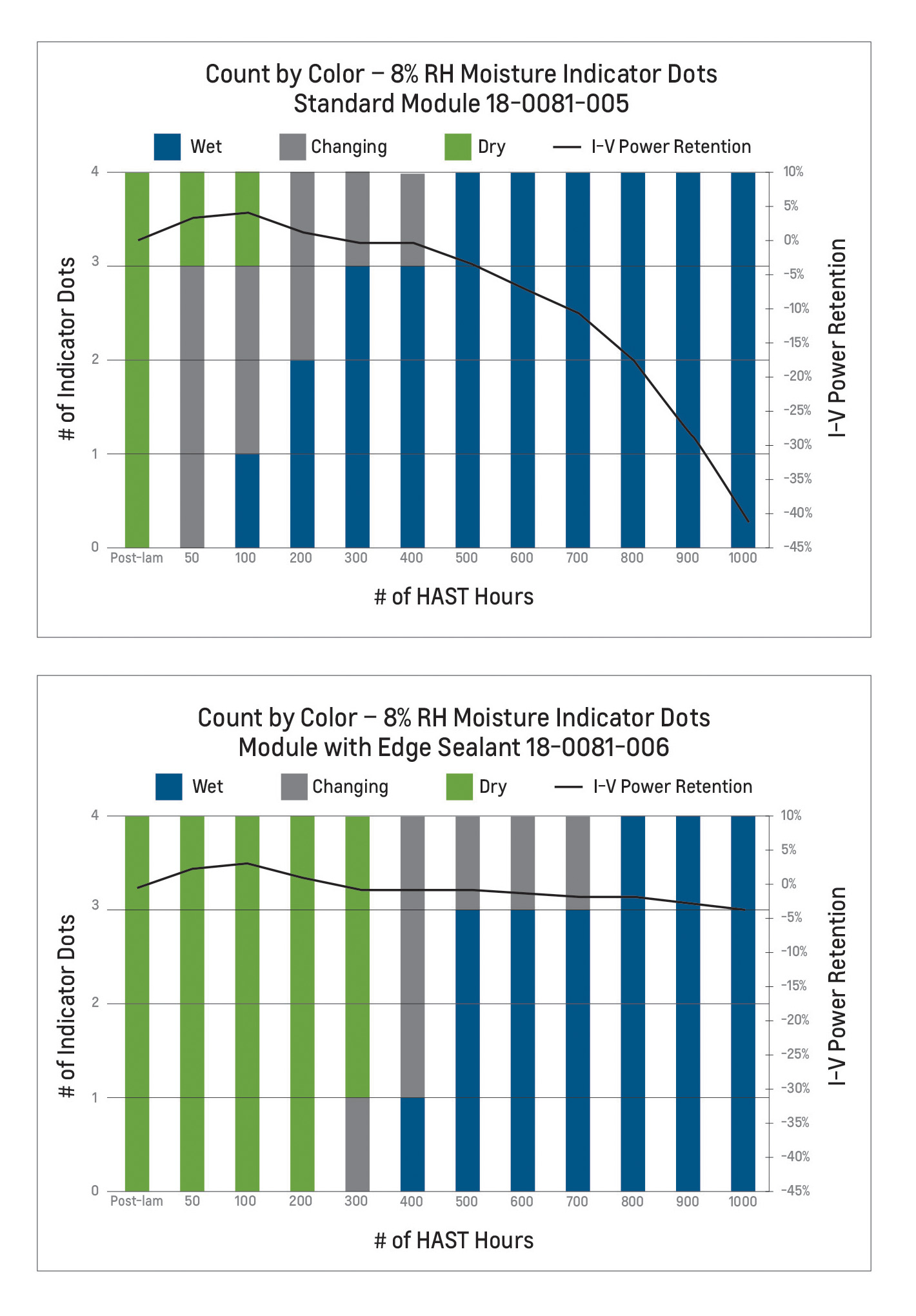

Both test units (a typical c-Si module and Quanex’s cemented joint unit) were outfitted with cobalt chloride indicator paper to visually show moisture ingress under testing conditions. Generally, testing procedures with excessive moisture are considered unrealistic to field exposures — but by using the cobalt indicators for tracking time to detect a low, but measurable moisture content, we were able to document the time for moisture to enter the active area and begin the degradation process. Power loss begins soon after the indicators change color at a low moisture level.

We exposed each to Highly Accelerated Stress Testing (HAST) at 120 °C and 100% relative humidity (RH) using a Hirayama HAST PC-422R7 chamber. Our teams tracked the ingress of moisture in the EVA using cobalt chloride indicator paper that changes color at 8% RH. Finally, we measured IV curves and took electroluminescence (EL) imagery to document our findings. The moisture density (g/m3) to which the modules were exposed is five times higher than in Damp Heat. Modules were subjected to 1,000 HAST hours.

Test Results

Our test results were clear: Using desiccated sealant should double the time before the initiation of moisture-induced degradation modes.

Moisture ingress as indicated by each unit’s cobalt chloride indicator (Figure 3) showed that conventional test units demonstrated infiltration by moisture as early as 100 HAST hours of exposure. These units were completely saturated by 500 hours. Comparatively, units constructed with edge sealants remained mostly dry through 400 hours and did not become saturated until roughly 800 hours of exposure.

*Click the image for greater detail

Figure 3: Conventional modules (top) indicated moisture ingress far sooner during HAST testing than modules using edge sealants (bottom).

Importantly, the results demonstrated that modules with edge sealant produced significantly more power over 1,000 hours of accelerated exposure compared to modules without edge sealant. Modules with edge sealant also maintained a much steadier fill factor throughout exposure.

It is worth noting that modules with and without edge sealant demonstrated similar shading at 500 hours in EL. However, between 500 and 1,000 hours, EL testing showed that conventional modules experienced significant darkening and exhibited behavior similar to 30-year-old outdoor modules in terms of EL appearance, power loss, and fill factor. We believe that the application of an edge sealant is likely to delay this type of degradation and potentially produce more power at 30 years than conventional c-Si module construction. As indicated by the test results, if the desiccated edge sealant can help delay moisture vapor as a stress factor for EVA modules, the timing and mechanism for module failures will likely also be delayed.

Finally, changing the placement of the cell due to our cemented joint configuration allowed us to reduce module area by over 4%, resulting in higher aperture efficiency; cost offset by reduction in area of glass placement; and lower overall module weight.

In all, our testing proved that applying an edge sealant in conventional C-Si modules has the potential to:

- Delay moisture ingress

- Help prevent loss of power over a module’s lifetime by significantly delaying moisture-related degradation mechanisms

- Maintain excellent environmental performance in high-heat conditions

- Allow for design to maximize cell area, increasing aperture efficiency

Panels with edge sealant could potentially extend their useful life by an additional 10 to 15 years without any other changes to existing design. We believe that further study will bear out that desiccated edge sealants can contribute toward longer and more reliable module performance in c-Si modules regardless of cell-design or encapsulant type used. Additionally, we expect that the incorporation of edge sealant will be necessary to perovskite cell modules more viable.

SolarGain® Edge Sealant from Quanex, as used throughout the testing procedures described in this article, is one such solution available to solar module manufacturers today. It is a polyisobutylene butyl rubber adhesive with integrated desiccant used as an edge sealant for PV modules, and has proven performance in thin-film PV module applications for the past 20 years. And as has been borne out by our research and testing, Solar Gain Edge Sealant can additionally help c-Si modules form greater protection for cells, connections, and transparent conductive oxide coatings from corrosion and degradation, resulting in slower module power decline over time.

Adopting such innovative measures to ensure long-term performance of PV modules may help improve bankability in the eyes of investors and customers. Edge sealants are one such solution, and it is worth thorough consideration.

Learn more at www.quanex.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!