Polyurethane Foam Encapsulant Protects and Lightens EVs

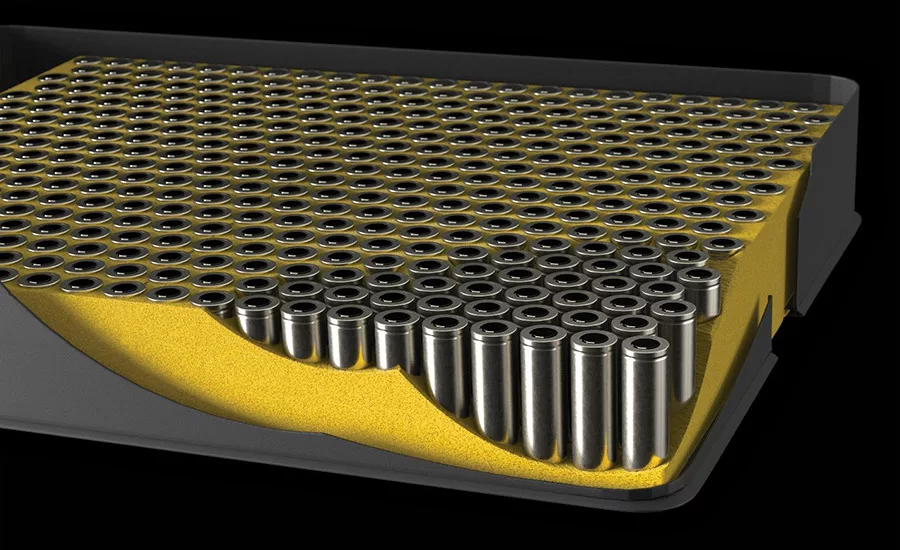

A two-component, ultra-low density, flame-retardant polyurethane foam is designed for potting and encapsulating lithium-ion battery cells in EV battery modules.

image courtesy of H.B. Fuller.

H.B. Fuller realized that if it formulated a product that was lightweight, low cost, and had NVH properties, it would fit the needs of today’s electric vehicle (EV) battery manufacturers. Creating an encapsulant that was fire retardant was also of upmost importance to H.B. Fuller to protect the battery from potential fire propagation. With all of this in mind, the company developed a product in 2016 that was years ahead of its time and loaded with future potential.

Created to provide NVH properties and damp vibration in EV battery pack modules, EV Protect 4006 is a two-component, ultra-low density, flame-retardant polyurethane foam, designed for potting and encapsulating lithium-ion battery cells in EV battery modules. This innovative material is easily integrated into battery module designs by filling voids, expanding five-fold, encapsulating all battery cells, and insulating the individual cells from each other.

In the unfortunate event of an accident, the encapsulant technology protects the adjacent cells from absorbing heat and reduces the chance of a major fire. If a cell(s) shorts, EV Protect 4006 absorbs the energy from the initial explosion(s) to prevent additional physical damage to the module and remaining cells. When the encapsulant interfaces with heat and flame, the material forms a strong charred layer, which prevents heat transfer to adjacent cells, protecting them from damage or failure. The prevention of fire and heat from transferring throughout the battery module is key to reducing thermal propagation. The product is a proven, lightweight, battery pack encapsulation solution that will ensure your battery design is safe and protected.

Additionally, with its ultra-lightweight characteristics, the encapsulant enables extended vehicle range and reduces overall carbon emission impact.

Dispensing is accomplished using a high-speed dynamic mixer head directly into the battery module. The low-viscosity liquid is easily able to flow and self-level at the bottom of the enclosure. Once leveled, the material will foam and rise to approximately five times volumetric expansion. After rising, the foam will crosslink and cure, creating a semi-structural interconnected foam that encapsulates all components within the module. In the event of a thermal event, the foam will absorb, isolate, and insulate the cells to mitigate thermal propagation.

The encapsulant offers the following benefits: reduction in thermal propagation, low viscosity and self-leveling, ultra-lightweight, vibration and impact resistance, outstanding insulation properties, no outgassing of hydrogen gas during curing, meets UL94V0 certification — flame protection/flame retardant, up to five-times expansion rate, cost effective with low-volume usage, fast processability, and non-corrosive.

Learn more at hbfuller.com/ev.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!