Home » Keywords: » electric vehicles

Items Tagged with 'electric vehicles'

ARTICLES

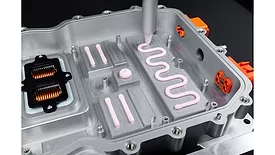

Demand Grows for Additives in EV Adhesives and Sealants as Consumers Go Electric

A recent study reports that in 2022, the global additives market for EV adhesives and sealants reached a value of $91.4 million.

February 23, 2024

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1706820052&width=275)