Thermally Conductive Gap Filler Withstands High Thermal Stresses

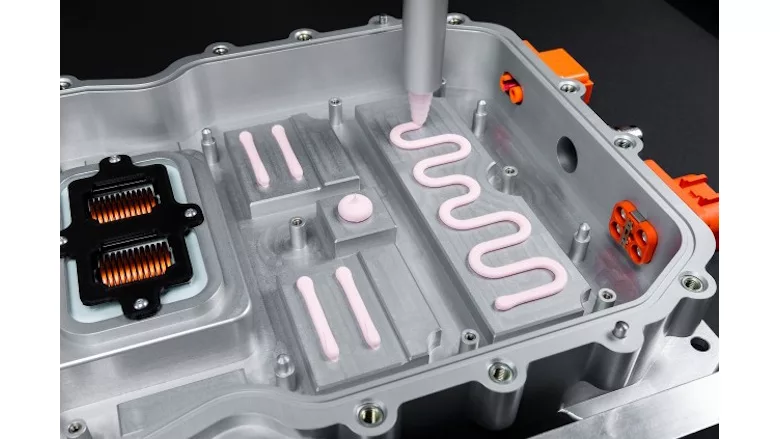

SEMICOSIL 9649 TC ensures that the heat generated when operating the vehicle is efficiently dissipated to the cooling elements.

SEMICOSIL® 9649 TC from WACKER was developed for power electronics applications in electric and hybrid vehicles. The silicone-based compound consists of a 2K system that cures at room temperature through an addition reaction to form an adaptable and repairable elastomer. It is an electrically insulating product with a thermal conductivity of approximately 4 W/mK.

Thermal resistance tests have shown that the product is particularly robust. For instance, SEMICOSIL 9649 TC can consistently withstand temperatures of up to 150 °C without any significant change in its thermal conductivity or other material properties. The product can also easily deal with thermal shocks that involve rapid temperature changes ranging from -40 °C to+150 °C. Thermal resistance measurements show that a bond made with SEMICOSIL 9649 TC between power electronics components and cooling systems remains intact even under such conditions. The thermal conductivity of the gap filler thus remains virtually unchanged even under dynamic thermal stressing.

SEMICOSIL 9649 TC is a non-sag material before cure. Its viscosity decreases with increased shearing, for example during mixing and metering. Its shear-thinning property is adjusted so that the compound can easily be fed by machine and applied as a bead. Processors can thus achieve a high metering rate and very high dosing accuracy.

In practice, a dispenser is used to apply the gap filler to the heat sink whereupon the power electronics circuit board is then pressed. During compression, a continuous film forms that conforms snugly to the surfaces of the two joining parts. In this way, surface irregularities and tolerances can be evened out perfectly. The film hardens between the joining parts to form a thermally conductive layer, which, thanks to its soft and flexible consistency, also absorbs vibrations and impacts. The product meets all relevant automotive industry quality standards and specifications.

Additional information is available at www.wacker.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!