Super Easy: Self-Adhesive Die-Cut Parts

Adhesive joining techniques are increasingly serving as innovation drivers, offering low weight, flexibility, and expanded design freedoms.

courtesy of Schreiner Group

The adhesive bonding tool kit.

The folding frame solution.

Applications include displays in washing machines and displays in cars.

Applications include displays in washing machines and displays in cars.

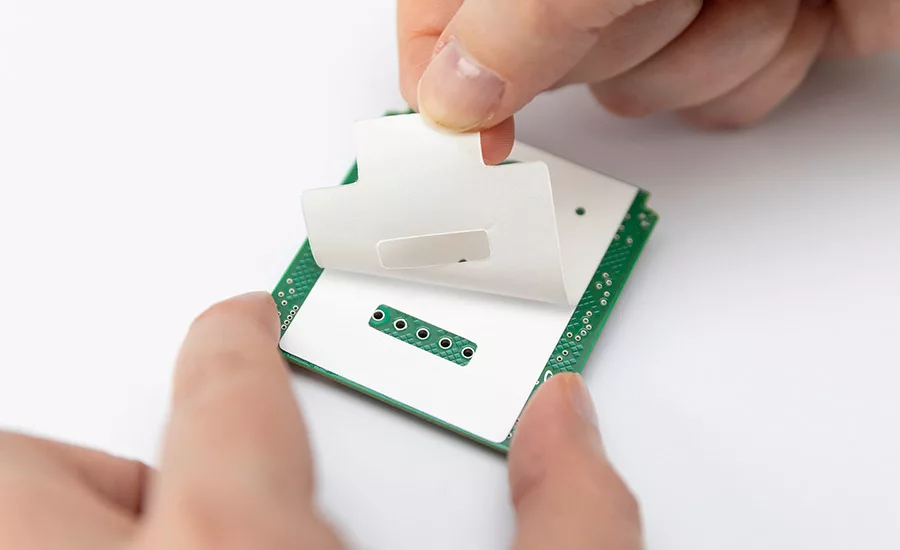

Die-cut parts enabling adhesive bonding of a PCB (printed circuit board).

A fully automatic assembly machine at work for double-sided adhesive tapes.

They join and seal components, or equalize heights: double-sided self-adhesive die-cut parts are true multi-talents, increasingly replacing screws as a heavyweight among traditional fastening methods. That’s because they have a weighty advantage: the pressure-sensitive adhesives (PSAs) they use are functional featherweights offering a wide variety of design, processing, and savings options, including cost, material, and cycle time. Their uses are as customizable and versatile as adhesive parts themselves. Here’s a sneak peek at how they work in the field.

For starters, let’s note that the good old screw hasn’t outlived its usefulness. But in industrial settings, where “lighter and smaller” is the name of the game and every ounce counts, adhesive joining techniques are increasingly serving as innovation drivers.

The opportunities created by high-tech adhesive bonding can best be compared to a well-stocked kit. Even though the kit’s various solutions all share a primary purpose — the joining of two materials — some may also address several needs simultaneously, such as protection, damping, or height compensation, depending on the application.

Fix It, Baby!

The benefits of self-adhesive bonding are obvious: besides their low inherent weight, these adhesive solutions offer unprecedented levels of flexibility compared to mechanical joining methods. A wide variety of materials can be combined, and the geometry of the die-cut parts allows expanded design freedoms.

Time and cost savings are another key factor. Case in point: by incorporating individual glue dots, die-cut versions used as installation aids — for example, in welding and soldering processes — assist in positioning and precisely affixing components in place. Glue-dot bonding ensures that enough soldering paste can migrate between the components, leading to a reliable, permanent bond.

There’s another important advantage as well. While welding and drilling significantly alter the surfaces of elements being joined together, adhesive bonding does not cause any damage to them.

Regardless of where they’re used, adhesive die-cut parts provide stability. However, this may occasionally prove to be a disadvantage, since once they stick, they stick. The bonds are hard, sometimes even impossible, to separate, which obviously increases the complexity and costs of exchanging adhesion-bonded parts.

Folding and Gluing

The Folding Frame System (see Image 2) is another alternative for joining components together by means of a circumferential frame, enabling maximum precision and tightness against external influences. The application system looks somewhat like a transparent waffle maker but, in combination with the folding frame, it beats conventional joining solutions in more ways than one. For starters, it eliminates the typical disadvantages of liquid adhesives: long curing periods that increase cycle times, and adhesive flow characteristics that typically prevent bonding with 100% precision and cleanliness.

The folding-and-gluing version using foam-based adhesive tapes and a matching application system is fast, easy, and eco-friendly; compared to a frame cut from an entire piece of material, in-process material consumption can be reduced significantly because the material to be bonded is produced lying side by side, saving space. In addition, the adhesive tapes stay connected to each other on the corners throughout the process — a major advantage that ensures subsequent tightness. Leak-proof, precisely positioned, and reproducible, these characteristics make such bonding solutions perfectly suited for attaching displays, among other applications.

Reliable Retention on Any Substrate

Die-cut parts enabling adhesive bonding of printed circuit boards (PCBs) in housings are another possible use, as illustrated in the image below. Produced as adhesive tape — for example, with an intermediate layer using film — the two adhesive sides can be adapted to the respective substrate: a thicker, stronger adhesive for the rough PCB and a thinner adhesive for the smooth housing. The intermediate film layer serves an additional purpose: it ensures electrical insulation of the PCB and the housing, preventing dielectric breakdown that might cause electronics to fail. The geometry of the die-cut part can be ideally adapted to the characteristics of bonded components. For instance, holes in the die-cut part can serve as lead-throughs for plugs, or small holes can ensure air exchange from one side to the other.

The die-cut part can be provided either with a continuous cover, or a die-cut cover with a tab, depending on the type of plans for processing and assembly. The continuous cover is suitable for processes in which the PCB is immediately glued into the housing. The cut-to-size cover with a tab enables subsequent adhesive bonding of the die-cut part to the PCB and housing.

Legible, Visible, Durable

When it comes to adhesive bonding of logos and emblems, attention is focused on other features. Manufacturers would like their brand names applied to products in an easily legible and visible way — and for it to remain there as long as possible. A sector that’s currently experiencing a significant boom exemplifies such applications: the e-bikes market. The sleek bikes are not only exposed to a wide range of weather conditions, but the electric motor typically sits on the crank drive — exactly the place impacted by dirt splash from the front wheel, where the oily chain is routed, and where the rider may accidentally scrape the motor housing. That means the area is a real “hardcore parkour” for self-adhesive die-cut parts. It goes without saying that the electric motor’s logo must not be impaired and remain perfectly in place. Looking the worse for wear is simply not an option.

To prevent that from happening, highly durable die-cut parts can reliably fix logos in place on the motor housing, and remain legible for several years despite exposure to adverse effects. These small parts can pack quite a punch.

Done!

Whether flat die cutting, rotary die cutting, plotting, or laser cutting, each method has its specific advantages and disadvantages. For large volumes, rotary die cutting is frequently used, while plotting is ideal for samples or very small volumes. Flat die cutting is the method of choice for processing very thick and firm materials, or very thick grades of foam. Laser cutting is perfectly suited for flexible materials, and the cuts can be performed with extremely high precision. However, laser cutting must always be considered on a case-by-case basis that considers the specific materials used, smoke development, and the related particulate formation.

In the application stage, it’s imperative to ensure that the technology and machines are carefully coordinated with the respective use case. Ideally, the functional parts and processing system are supplied by a one-stop shop. Rolls, sheets, or stacks are the commonly used methods for preparing and delivering the final product. The liberating design freedoms that self-adhesive products offer also extends to customizable forms of delivery.

Sticky Powerhouses

Self-adhesive die-cut parts join, protect, equalize, and insulate, and “incidentally” optimize manufacturing processes, among other benefits. The nearly unlimited freedom of design they offer — from miniature sizes to complex geometries — makes it possible to tap new creative potential and uses. That potential is far from fully exploited across a wide array of industries.

Learn more about Schreiner Group at www.schreiner-group.com/en/.

Article images provided by Schreiner Group.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!