Releasing the Potential of Sustainable Products

Recycling silicone release liners provides environmental and economic advantages as companies endeavour to reach sustainability goals.

image supplied by Techlan

A roll of release paper.

Waste rolls.

Illustration of the circular economy.

The cleaning process.

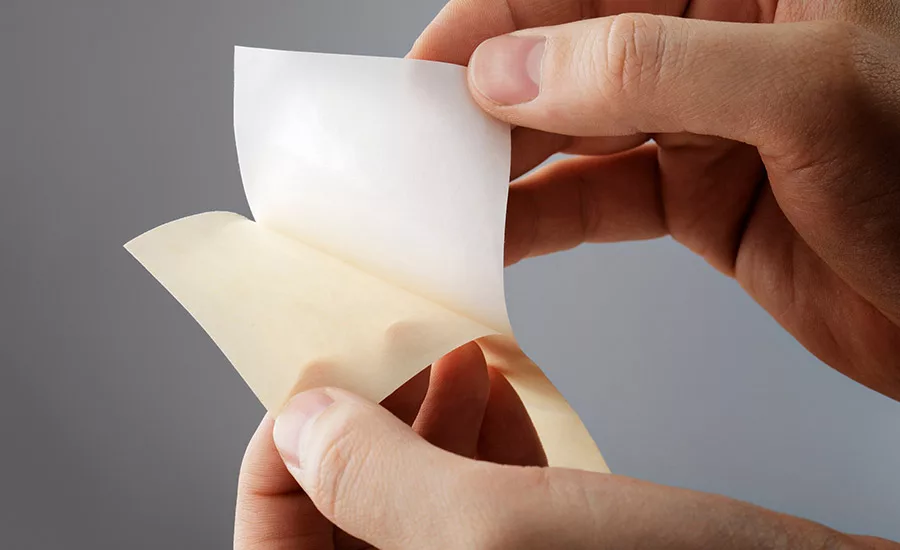

Silicone release liner

As industries strive to reduce their environmental impact and embrace eco-friendly alternatives in their products and supply chains, the significance of silicone release liners often goes unnoticed. Release liners are essential components in the adhesives and sealants industry, facilitating the manufacturing, transportation, and application of adhesive and sealant products while ensuring their quality and effectiveness. They are widely used in various manufacturing processes, hold immense potential for recycling and reusing, making them valuable in our quest for a sustainable future. This article sheds light on the importance of recycling silicone release liners, emphasizing their environmental impact, economic advantages, and role in fostering a circular economy.

Silicone release liners are made from materials such as paper or film and coated with a layer of silicone. They act as protective barriers for adhesive and sealant product applications within a variety of sectors ranging from adhesive tapes, butyl, foams through to sealants and assembly tapes. They are crucial to ensure that the adhesive remains tacky and effective until it is applied, as well as simplifying handling and application, particularly in large-scale manufacturing processes. However, their widespread use also poses a significant environmental challenge when it comes to their disposal.

The release liner industry has evolved and adapted over the years in response to changing market demands, environmental concerns, and technological advancements. It continues to evolve, driven by a combination of environmental concerns, new technology, and regulatory changes. These developments aim to make release liners more sustainable, efficient, and suitable for a wide range of applications.

There are a number of stages within the release liner supply chain, however the release liner manufacturing process remains a high energy and raw material consuming process. Paper production requires significant energy inputs, contributing to carbon emissions. The paper and pulp industry is among the top five most energy-intensive industries globally and is positioned as the fourth-largest industrial energy user. It accounts for 6% of global industrial energy consumption. In 2022, the pulp and paper industry generated just below 2% of all emissions.1,2

When silicone release liners are not recycled, they often end up in landfill, exacerbating the global waste crisis. These liners are typically non-biodegradable and their disposal in landfills contributes to the emission of greenhouse gases, further fueling climate change. The recycling of silicone release liners not only diverts them from the waste stream but also reduces the demand for raw materials, energy consumption, and the emissions associated with their production.

The recycling of release liners offers a unique opportunity to conserve energy and resources. By reprocessing them, valuable materials like paper and film can be recovered and utilized in the manufacturing of new products. Recycling reduces the reliance on virgin materials, thereby diminishing the energy-intensive processes involved in their extraction and production. Additionally, recycling release paper helps conserve trees, reduce water usage, and minimize the environmental impact of the paper industry.

Techlan Ltd, an industry leader in silicone release liner recycling, has emerged as a pioneer in this field. The company has developed an advanced recycling process that effectively diverts rolls of release liner from landfill and manufactures them into high-quality, 100% recycled release liners. Through cutting-edge technology and expertise aligned with the principles of a circular economy, it has revolutionized the recycling of silicone release liners. Its Re-Liner product is a substitute for prime-grade release liner, with no compromises on quality or cost.

The company has created a circular economy model keeping materials for reuse within the supply chain. Liners, that were previously used once and sent to landfill, are now processed by Techlan to create Re-Liner – a high-quality recycled release liner for resupply.

Circular Economy Models

There are two circular economy models for the recycling of release liners. The first model is open loop, where used material from one sector is processed into Re-Liner for resupply and reuse as a high-quality material for another sector.

The second model, a closed-loop model, offers even greater benefits to customers. After a first use, liners are sent to Techlan for processing and then returned to the customer as Re-Liner for reuse. Remarkably, Techlan can repeat this cycle up to 11 times using the same liner without compromising its quality. It means that every tonne of Re-Liner replaces up to 11 tonnes of prime-grade release liner.

This significantly reduces reliance on prime-grade material and so minimizes waste and the environmental impact associated with its production and disposal. It illustrates how recycling can also make good business sense by reducing the cost of raw materials.

The company prioritizes efficiency and quality assurance in its recycling operations. Through meticulous sorting and cleaning processes, Techlan ensures that the recycled materials meet stringent industry standards. The recovered materials undergo a thorough cleaning process to eliminate adhesive residues and contaminants, resulting in high-quality recycled materials suitable for various applications. By maintaining the integrity of the recycled liners, Techlan enhances the value and versatility of the materials in the marketplace.

Governments, organizations, and companies around the world are setting net-zero emissions targets as part of their climate action plans. Achieving net-zero emissions is considered a critical step in limiting global warming and mitigating the impacts of climate change. Many sectors are already examining their supply chains to look at using carbon reducing products to achieve net zero.

Re-Liner can completely replace existing prime-grade release liners without compromising on quality and creates a measurable carbon saving of 670 kg / 1,000 kg consumed. As businesses strive to enhance their sustainability, adopting Re-Liner becomes a pivotal strategy to reduce their carbon footprint.

Effective recycling of silicone release liners requires collaboration and industry leadership, and Techlan actively engages with manufacturers, suppliers, and other stakeholders to establish partnerships and promote sustainable practices. By sharing their expertise and knowledge, the company encourages the adoption of recycling initiatives throughout the industry. This proactive approach fosters a culture of sustainability, drives innovation, and inspires others to embrace responsible waste management practices.

By diverting waste from landfill, conserving energy and resources, and mitigating emissions, companies can make significant contributions to environmental preservation. Embracing recycled release liners not only benefits the planet but also enhances reputation, engages stakeholders, and aligns with consumer preferences. By harnessing carbon-reducing products, companies can pave the way towards a greener future while driving positive change in their respective industries.

For more information on Techlan, visit www.techlanltd.co.uk.

Footnotes:

- “Tracking Pulp and Paper” iea paper, https://www.iea.org/energy-system/industry/paper

- Lipiäinen, S; Kuparinen, K; Sermyagina, E; Vakkilainen,E. Pulp and paper industry in energy transition: Towards energy-efficient and low carbon operation in Finland and Sweden. Sustainable Production and Consumption 2022, 29, 421-431

References:

Smith, J. (2018). The Environmental Benefits of Recycling Silicone Release Liners. Journal of Sustainable Manufacturing, 25(2), 45-57

Green, A. B. (2021). Recycling Technologies for Silicone Release Liners: A Comprehensive Review. Waste Management & Research, 38(4), 215-230

Techlan Ltd. (2023). Sustainability Report: Recycling Initiatives. Retrieved from J Clean Prod, 277 (2020), Article 124018

International Energy Agency, Energy Systems, Industries, Paper

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!