The New Frontier of Green Construction: Creating a More Sustainable World through Mass Timber and Adhesives

Mass timber has become an increasingly popular alternative to minimize construction’s environmental impact, offering a renewable resource with a notably smaller carbon footprint.

Brock Commons, a student residence hall at the University of British Columbia in Vancouver, Canada, is constructed of mass timber panels by Strucurlam using Henkel adhesives. Use one of prefabricated mass timber panels helped to increase the construction speed of the 53-m-tall structure.

Each year, the debris produced during construction—and in particular, building demolition—represents more than 90% of the total construction and demolition debris generated and sent to landfills in the U.S. That equates to approximately 145 million tons of debris.1

Naturally, producing that much waste has a clear and sizeable impact on the environment. In recent years, to minimize construction’s environmental impact, mass timber (a structural load-bearing element made from solid lumber glued to form columns, beams, and large format panels) has become an increasingly popular alternative, offering a renewable resource with a notably smaller carbon footprint.

Benefits of Mass Timber

Unlike concrete and steel, which are mined from the ground and never replaced, mass timber is produced from a renewable resource and can be used to construct virtually anything, including high rises, multi-family homes, office buildings, factories, and warehouses. In addition, it’s lighter than concrete or steel, so less carbon is emitted in transit. Indeed, mass timber sequesters one ton of CO2 per cubic meter, vs. steel that produces 15 tons per cubic meter or reinforced concrete that produces approximately 2.5 tons.

What’s more, mass timber improves building performance, is earthquake resistant, and is engineered to be fire safe. There’s even an emotional benefit: According to industry studies, people feel calmer and more productive in wooden buildings than they do in concrete or steel structures.2

Over the past few years, through the heightened use of mass timber, the industry has made great strides in embracing the new frontier of green construction. As it continues to evolve, new materials, including certain adhesives that are already available, are being explored in tandem—both for their sustainability benefits, as well as their ability to improve productivity and the longevity and strength of mass timber structures.

Cross-laminated timber beams are constructed by adhering layers of solid-sawn lumber with adhesive. This improves the structural integrity and rigidity of the beam or panel.

Increasing Acceptance

Bonded mass timber is increasingly gaining acceptance in construction, as more and more projects adopt the use of these materials. In 2019, for example, Walmart and Structurlam, a leading mass timber manufacturer in North America, announced they were partnering on a new production site that will produce mass timber to build Walmart’s new headquarters in Arkansas. The Walmart facility will utilize an estimated 1.7 million cu ft of regionally sourced lumber, making it the largest mass timber campus project in the U.S. to date.

Walmart and Structurlam are just the beginning; architects around the world have already begun constructing mass timber buildings, schools, and homes of their own using this sustainable practice. For example, “Mjøstårnet,” an 18-story timber building located in Brumunddal, Norway, remains sustainable and reliable thanks to the tower’s mass timber makeup.3

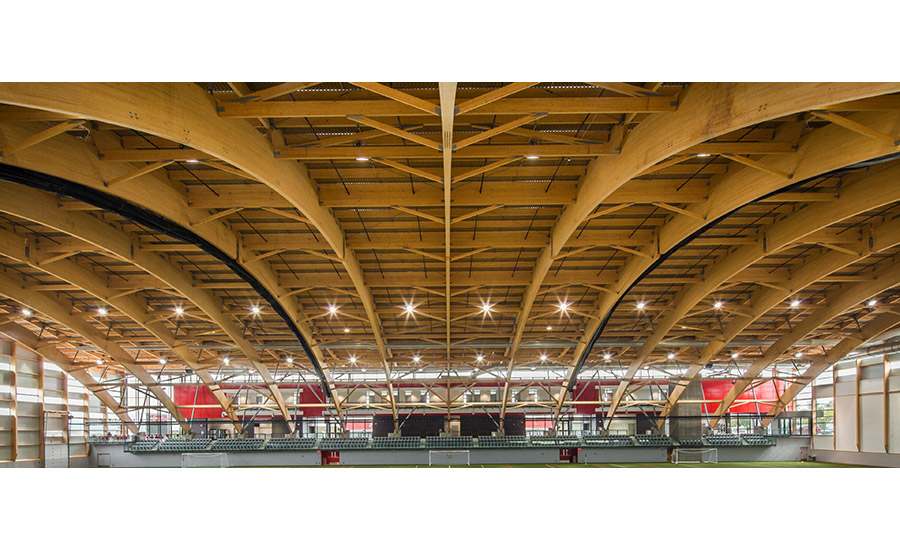

Stade Telus, a 97,000-sq-ft sports facility at Laval University in Quebec City, Canada, was constructed with Nordic Structures’ mass timber applications, which incorporate Henkel’s adhesive. These material choices resulted in approximately 1,500 fewer tons of CO2 being emitted during construction.

In the end, the industry’s uptick in mass timber use is a pivotal step in its pursuit of sustainability. Indeed, a recent study by The Marshall Effect found that if mass timber construction continues to grow as it has, the building industry can expect to have a negative carbon dioxide impact by 2034, with mass timber projects offsetting concrete and steel.4 With this in mind, it will be critical for architects around the world to continue to use mass timber and adopt the materials for their construction projects, when possible.

For more information, visit www.henkel-northamerica.com.

Note: Images courtesy of Henkel.

References

- Advancing Sustainable Materials Management: Facts and Figures Report [Fact Sheet], U.S. Environmental Protection Agency, 2018, www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management.

- Lowe, Graham, “Wood, Well-being and Performance: The Human and Organizational Benefits of Wood Buildings,” Forestry Innovation Investment, 2020, www.naturallywood.com/resource/wood-well-being-and-performance-the-human-and-organizational-benefits-of-wood-buildings/.

- Block, India, “Mjøstårnet in Norway becomes world's tallest timber tower,” Dezeen, March 19, 2019, www.dezeen.com/2019/03/19/mjostarne-worlds-tallest-timber-tower-voll-arkitekter-norway/.

- “North American Mass Timber State of the Industry Report,” The Marshall Effect, 2020, www.smartlam.com/wp-content/uploads/2020/08/The-Marshall-Effect-SmartLam-NA.pdf.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!