Embracing Circularity: Making Bio-based Adhesives with Olive Pits

The incorporation of olive stone powders into epoxy, polyurethane, and other polymeric systems can dramatically improve a material’s environmental footprint.

aerogondo / iStock / Getty Images Plus

A lignocellulosic material, olive stones are crushed in the mill when creating olive oil.

Olive stone powders and particles in various grain size ranges.

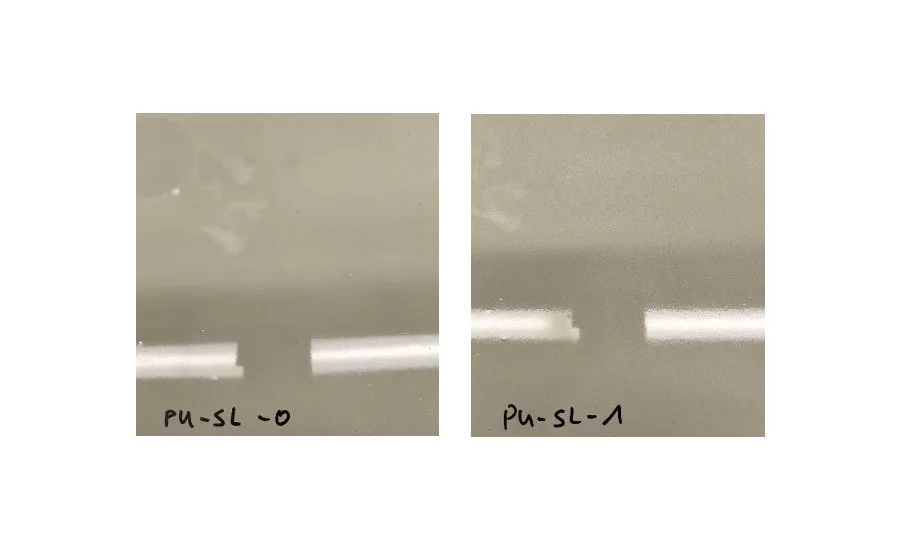

Comparative overview of filler systems in an aliphatic polyurethane (PU) system: Left side: a ready-to-use formulation filled with 10% quartz sand, micron range 0.1-0.3mm. Right side: a ready-to-use formulation filled with 10% Olea FP, micron range 0.1-0.315mm.

The adhesives and related industries have seen a noticeable shift towards natural materials. While most formulations have conventionally been made from non-recyclable, fossil-based polymer systems, plant-based solutions have recently become a market success. These include, besides plant-based binder chemistries, functional fillers, reinforcing fibers, and texture particles.

BioPowder, a young company founded in 2017, came to the market with a purpose: to support material scientists in reducing their environmental footprint while enhancing functional properties. The team, coming from a biomass background, has developed techniques to process by-products from the food industry into powders and particles. One raw material has gained prominence thanks to its unique functional properties: olive stones. Crushed in the oil mill as part of the olive and later removed of shell and pulp residues, this lignocellulosic material combines low density with strength, stability, and hardness. Micronization, i.e. milling and sieving into defined micro-meter ranges, creates powders and particles for multiple applications. In polymer systems, BioPowder’s performance powders can add value as reinforcing agents, adhesion enhancers, functional fillers, curing accelerators, and decorative particles.

As a company with upcycling as the main product concept, BioPowder promotes circular principles. Reduce-reuse-recycle: operating along these lines requires a holistic approach from the raw material up to the final applications of the natural particles.

BioPowder is part of an ecosystem of olive and fruit processing value chains. Besides transforming the by-products (fruit pits, seeds, and shells) and giving them a second life, the company creates innovative markets for compostable micro-particles, always with the goal of supporting adhesive and sealant manufacturers on their journey towards more sustainability. Sustainability, a word that appears over-used these days, should be filled with meaning and a clear action plan. Otherwise, it will remain a label with little impact.

Current sustainability initiatives in the materials industry focus mainly on recycling: there is consensus about manufacturers’ responsibility to provide valid end-of-life solutions, and recycled content has become a number one strategy to reduce a product’s environmental impact. The team behind BioPowder believes that holistic sustainability should start at the material design stage. Tackling climate change and the ever-growing amounts of waste should also involve conscious resource consumption, re-use/re-purposing, and extended product lifespans.

BioPowder partners with researchers and manufacturers to reach a two-fold goal: 1) reduced carbon and environmental footprints, and 2) identify functional benefits of end products for diverse industrial applications. In other words, the company offer well-rounded support for manufacturers’ journey to making greenwashing-free products that work.

Reduced Footprint

Commonly used tools to perform a product’s lifecycle analysis (LCA) often focus on emission-based data, such as the carbon footprint, which is deemed crucial in the context of greenhouse gas emissions and their role in climate change. However, to fully quantify a product’s environmental impact, it is crucial to look at it as part of a wider context. This is what the ecological footprint measures. In other words, it reflects the amount of natural resources an organization uses in relation to the availability of such resources, hence, its impact on the depletion of natural ecosystems.

BioPowder’s waste-to-value processes are free from chemicals, resource efficient, and local. As a result, carbon emissions values are kept to a minimum. Considering the origin of olive stones, it becomes clear that they are in fact a source of bio-carbon. Research by the International Olive Council suggests that olive trees absorb around 10kg of CO2 per kg of harvested olives. With these facts in mind, the olive-processing ecosystem including oil and by-products is a carbon-negative one.

Consequently, the incorporation of olive stone powders into epoxy, polyurethane, and other polymeric systems can dramatically improve a material’s environmental footprint. Besides supplying compostable particles, BioPowder is expanding its R&D capabilities to support end-product development, i.e. testing in bio-based binder systems, particle surface functionalization, and coloring.

Unique properties and functional benefits of olive stone particles:

1. Reinforcing properties: Olive stone particles, with a hardness of approx. 3.5 (Mohs), enhance the impact and abrasion resistance of a polymeric compound, leading to a longer lifespan of performance materials. Examples include reinforced natural and synthetic rubber, polyurethane coatings, silicone-based sealants, and filled PVC.

2. Weight-reduction: Particularly beneficial for components in industries where every gram counts. Sealant systems in automotive, medical, or aerospace applications are just a few prominent examples. Polymers, both bio-based and conventional, are often filled with mineral powders to achieve hardness and stability. Replacing these heavyweight fillers with olive stone particles can lead to a lower material requirement and an overall weight reduction of the final compound.

3. Decorative and anti-skid effects: Customizable particle sizes are easy to apply in various (adhesive) coating systems. Filled masterbatches can be created with new decorative effects and an elevated bio-content.

4. Hydrophobicity and barrier properties: In addition to fully natural powders, BioPowder offers a range of surface-treated particles that enhance compatibility with different polymer chemistries. This functionalization improves hydrophobicity, reduces oil absorption, and adds to the overall longevity of bio-based performance polymers.

Application Lab

With a high degree of customization, both in terms of particle shape, micron ranges, and surface functionalization of the particles, the upcycled material solutions can be tailored to a variety of polymeric formulations. Besides being a one-stop shop for solid powder additives, BioPowder can now solve customers’ R&D challenges. Oftentimes, adopting a bio-based material design strategy requires numerous formulation upgrades, mostly with uncertain outcomes, long testing times, and considerable expenses. With its Application Lab and through partnerships with pilot customers, specialized institutes, and sound market experience, the company can perform dedicated R&D, provide guide formulations for real market scenarios, and offer outside-the-box advice with proven evidence.

Using its multidisciplinary know-how, the company can create ready-to-use solutions at the intersection of various industries. In particular, adhesives are closely linked to coatings due to their chemical and functional similarities. Therefore, BioPowder’s analytical approach reflects the market requirements and focuses on identifying unique benefits such as reduced curing times.

Last but not least, the company’s circular approach goes hand-in-hand with a growing offer of bio-based resin systems. The adhesives market has seen a shift towards more eco-friendly formulations such as water-based polymer dispersions to eliminate organic solvents, or bio- polyols for VOC-free polyurethanes. Those systems have demonstrated excellent compatibility with plant-based, reactive filler systems — an aspect that can further ease sustainable material design.

Driving Circularity

BioPowder's approach represents a noteworthy shift in the materials industry towards sustainability. The company’s use of olive stone particles derived from food-industry by-products showcases a commitment to upcycling and circular principles. By addressing the environmental impact at the material design stage, BioPowder advocates for a holistic sustainability perspective, going beyond the current focus on recycling. Collaborating with composite makers, the company’s efforts aim to genuinely reduce carbon footprints while offering functional benefits to end products.

In a landscape where the term sustainability is often overused, BioPowder's endeavors to stand out as a practical contribution towards minimizing waste and creating environmentally conscious materials with real-world applications.

For more information, visit www.bio-powder.com.

Images within article courtesy of BioPowder.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!