Manufacturing and Assembly: Automate, Create Value and Deliver Bottom-Line Results

Given the uncertainty of the economy creating extreme push outs and pull ins with customer orders, companies that can successfully deal with uncertain and changing conditions will thrive.

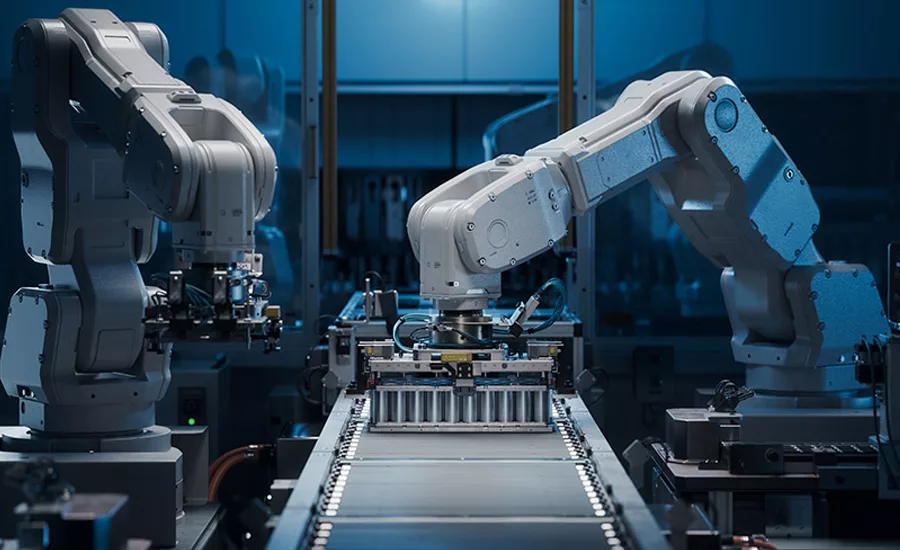

SweetBunFactory/iStock/Getty Images Plus

During these volatile, uncertain, complex, and ambiguous (VUCA) times, successful manufacturers are finding ways to automate, create value, and deliver bottom-line results. From extreme geopolitical and supply chain risk to ever increasing customer expectations, manufacturers are experiencing an unprecedented need to set a new course to create sustainable bottom-line results. Continuous improvement is no longer enough.

Automate and Digitize

Given the uncertainty of the economy creating extreme push outs and pull ins with customer orders, only those companies that can successfully deal with uncertain and changing conditions can thrive. Better utilizing ERP, quoting, and CRM systems to automate planning and scheduling processes enables quicker pivots to satisfy changing customer conditions with greater stability for operations. Upgrading processes to increase predictability and efficiency improve customer value and profitability. Similarly, automating operational processes such as using robotic welders can provide greater flexibility as customer requirements change while mitigating costs

For example, an industrial equipment manufacturer receives multiple order changes and sales order drop-ins every week for an engineer-to-order (ETO) product. Given the product complexity, requiring fabrication and assembly operations, quick changes require close coordination with Engineering, Operations, Project Management, and Customer Service. Thus, by upgrading the production planning processes and use of ERP functionality, they automated communications with exception messages, flags, and projected ship dates to align all parties on the same page.

Upgrade the End-to-End Process

Although upgrading the use of ERP and advanced technologies is critical in today's environment, it will not lead to success without being accompanied with the appropriate process upgrades. For example, although the industrial equipment manufacturer upgraded its functionality relatively early on, results did not occur because the process had to be unscrambled, simplified, and upgraded. As process improvements were rolled out with extensive training, education, and engagement, additional functionality upgrade opportunities arose in the iterative and collaborative process. The additional upgrades improved the efficiency for the planners.

The process improvements included a more efficient deep dive into customer requirements, a streamlined evaluation of operations sequencing options, and a more detailed, automated view of staffing and crewing configurations. By concentrating on these enhancements, they increased production output overall while ensuring the right items were available at the right time to satisfy customer requests at the lowest freight.

In addition, they rolled out a SIOP (Sales Inventory Operations Planning) process to align their production schedules with manufacturing capacity and sales requirements. This resulted in several "Connect" meetings with Engineering to prioritize workloads, Operations to proactively staff and train, Sales to deep dive into quotes, and with Purchasing to ensure material availability. These upgrades and collaboration meetings stabilized the schedule, provided visibility to capacity bottlenecks to reallocate and/or expand capacity, and drove increased productivity and profitability.

Automation Equipment for Added Flexibility

The manufacturer also installed robotic welding equipment at strategic facilities throughout its network. This allowed it to scale up/down rapidly with changing customer conditions during volatile and uncertain times, thereby increasing customer value with rapid responses. It also improved its cost structure as it didn’t have to bring on workers, provide training, and didn’t experience additional scrap during learning curves.

Delivering Bottom Line Business Results

Automation of mundane and repetitive tasks increases productivity, reduces cost, and improves quality and consistency. Upgrading processes in conjunction with the better utilization of ERP and supply chain technologies will simplify the complex and automate the details so that your team can spend most of their time on exceptions and adding value instead of crunching numbers. These priorities will improve customer value and deliver profitable growth.

For more information, contact the author at landerson@lma-consultinggroup.com or visit www.lma-consultinggroup.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1653417027&width=200)