WACKER Starts Hybrid Polymers Production at Nünchritz Site

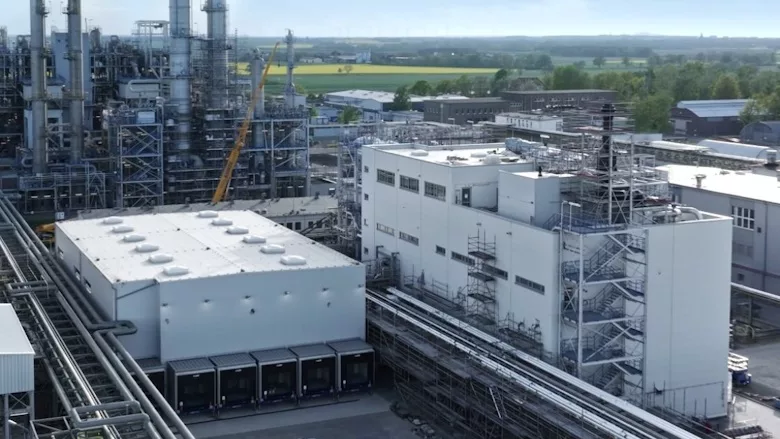

New production facility for hybrid polymers: WACKER has started producing hybrid polymers at its Nünchritz site in Saxony, Germany. Photo courtesy of WACKER.

WACKER has started production of hybrid polymers at its site in Nünchritz, Germany. WACKER reports that the new production facility is currently undergoing ramp-up. Hybrid polymers serve as binders for high-quality adhesives and sealants and are popular because they are easy to use. Such binders are increasingly being employed by manufacturers of construction and assembly adhesives, parquet-flooring adhesives, or liquid waterproofing membranes for roofs and balconies. The alpha-silane-terminated hybrid polymers from WACKER enable the formulation of tin-free, consumer-friendly products. The new investment created 50 new jobs at the site.

The new high-speed facility will replace the existing production plant at the company’s Burghausen, Germany, site and will substantially boost production capacity for hybrid polymers. “With annual growth rates of well over five percent in some cases, the market for hybrid polymers is extremely attractive for us,” explained Managing Board member Christian Kirsten. WACKER is already a leading manufacturer of silane-terminated polymers. Kirsten added, “Expanding our production puts us in a position to support the growth of our customers. The facility thus aligns with our strategy of increasingly focusing on tailor-made specialties that offer great innovation potential, high vertical integration and high customer benefit.”

The ultra-modern production line at the Nünchritz site features a range of technical innovations. The highly integrated combination of key working steps within the building keeps distances short and makes for an efficient, continuous production processes. “The new facility’s production capacity will increase our output many times over,” said Tom Koini, head of the Silicones business division. It can also be expanded to accommodate future growth, he added. “If the market continues to grow as dynamically as before, we will be able to significantly boost our production capacity once again.”

Hybrid polymers rank among the business division’s most important growth fields. Offered under the name GENIOSIL® STP-E, the products serve as silane crosslinking binders for formulating high-performance adhesives and sealants for industrial and construction applications and, more recently, for liquid waterproofing membranes.

Since hybrid polymers based on WACKER’s proprietary alpha-silane technology can also be used to produce tin-free products, they are environmentally and consumer-friendly. “Aspects like these, alongside performance, are becoming more and more important in the formulation of adhesives and sealants. They are what makes our hybrid polymers so attractive to customers,” said Koini. “The alpha-silane technology allows us to develop customized binders for a wide variety of adhesive types. Demand for such products will continue to see strong growth in the coming years.”

Learn more about WACKER and its products at www.wacker.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!