Creating Healthier, More Efficient Building Envelopes with Spray Foam Technology

As greater energy efficiency is a top target of all manner of buildings, spray foam insulation technology is an effective way to make it happen.

Spray foam technology can help to improve thermal performance and minimize air leakage within the building envelope.

A building's energy efficiency is one of its most important characteristics, helping to cut energy costs, contribute to owner sustainability goals, enhance occupancy comfort, and more. And today, there are more ways to enhance building efficiency than ever before. Energy-efficient lighting, modern HVAC technology, and rooftop solar panels are just some of the strategies homeowners and organizations have undertaken.

But one of the most effective is also one of the simplest. The application of spray polyurethane foam insulation can enable a home or building to remain efficient and comfortable no matter the elements outside. In fact, spray foam insulation can help contribute to a more resilient and healthier building envelope in a variety of ways, delivering enhanced value, and helping your operations avoid downtime, lost production, expensive maintenance repairs, safety issues, and other concerns — especially when installed by qualified professionals.

This article will examine why spray foam represents an ideal insulation solution for a broad range of applications, the most effective target areas for spray foam insulation, and the benefits that can be achieved following installation.

Why Spray Foam?

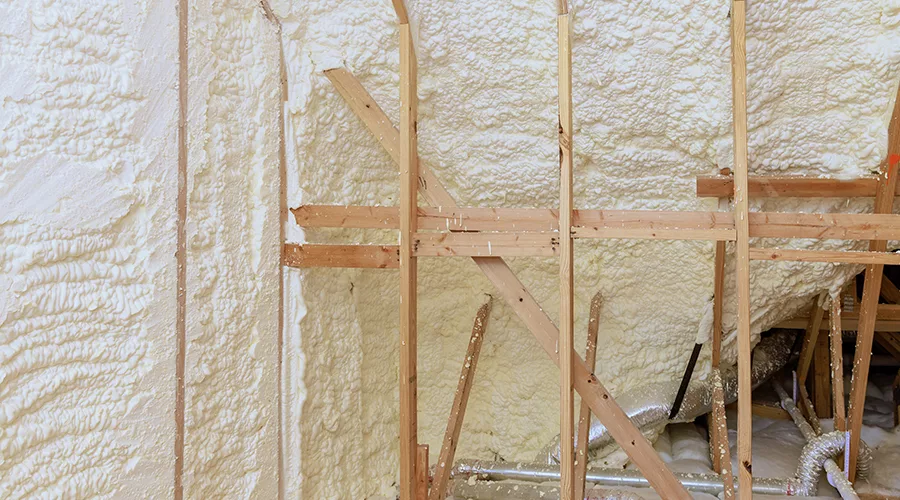

Spray polyurethane foam, broadly, is a high-performance insulation material created by mixing two liquid components that react and expand to form a rigid foam. It is sprayed directly onto walls, roofs, floors, and cavities, where it expands to fill gaps, cracks, and seams.

Compared to other insulation types like fiberglass or cellulose, spray polyurethane foam maintains one of the highest R-values per inch. This allows it to provide industry-leading thermal resistance, thus reducing heat loss and minimizing energy costs for heating and cooling, helping to enhance the overall efficiency of any building.

And that’s not all. Spray foam insulation also works as an air and moisture barrier in the right applications. Unlike traditional insulation materials, spray foam expands to fill gaps and cracks, effectively sealing air leaks, reducing drafts, and improving indoor air quality. Further, as a moisture barrier, spray foam can help prevent mold and mildew growth, which is crucial for maintaining a safe and healthy environment.

Other benefits of spray foam insulation include:

- Structural reinforcement. Spray foam insulation adheres to surfaces and hardens, adding rigidity to walls and roofs, which can improve the building's structural integrity.

- Noise reduction. The dense composition of spray foam insulation helps to absorb sound, reducing noise pollution from outside or between different areas within the building. This can be ideal for office buildings, apartments, and mixed-use properties where soundproofing is important.

- Longevity. Spray foam insulation is highly durable and does not sag, shrink, or deteriorate over time. If installed properly, it requires minimal maintenance, providing long-term performance and value.

New sealant formulations are designed to minimize VOC emissions and use eco-friendly materials, contributing to lower carbon footprints in construction projects, further contributing to an enhanced sustainability profile. For example, next-generation low-global-warming-potential blowing agent technology enables today's spray foams to deliver reliable application in a variety of seasonal conditions, as well as optimal foam dimensional stability and consistent reactivity and insulation performance.

Ideally, a high-performance spray foam product should also deliver benefits both for end users and applicators as well. During application, a smooth and controlled spray pattern can deliver superior yield, less rework, and uniform thickness without the need for touch-ups. These attributes can help lower labor costs for a product.

In any case, it's important to be certain that your selection meets the criteria for its intended application. It is not uncommon to encounter spray foam products that are advertised for use as a sealant, as insulation, or both. But sealants and insulation must meet respective codes; testing requirements and specifications, including U.S. building codes, FTC labeling or testing requirements, OSHA regulations for hazard reporting, and PUR product standards. Each product should also come with a safety data sheet (SDS) and technical data sheet (TDS) for proper operating procedures, product stewardship guidelines (including how to dispose of empty cannisters), and other critical information. These items should always be available from the foam supplier; if they aren’t, it may be a sign of a misleading product.

Optimal Areas for Spray Foam Application

Spray foam can be applied throughout the building envelope to achieve the greatest benefits. Walls, roofs and attic spaces, basements and crawl spaces, and windows, doors, and other fenestrations are some areas where the technology can be particularly effective, helping to improve thermal performance and minimize air leakage.

Gaps around windows, doors, and other openings can also be targeted with spray foam sealants (which are distinct from insulation products, as noted earlier in this article) to further prevent drafts and leaks. While visual inspection can help determine areas where spray foam will be effective, more advanced diagnostic methods can be applied by trained professionals that can more comprehensively determine air leak rates and problem areas throughout the entire building envelope.

For example, a blower door test is a common method to measure air exchanges per hour and identify common leak points. The test deploys a powerful fan that is temporarily mounted into the frame of an exterior doorway. After calibrating the device, the fan pulls air out of the building, lowering the air pressure inside. The higher outside air pressure then flows in through all unsealed openings such as gaps, cracks, or wiring penetrations. If conditions don't allow for lowering the pressure in the home, the fan may also be operated in reverse, with air pressure increased inside the home.

Infrared cameras can also be used to inspect walls, ceilings, and floors to find specific locations where insulation is missing and air is leaking. Elsewhere, a nontoxic smoke pencil test can also be used to detect air leaks. These tests determine the air infiltration rate of the facility as well as the specific points that will most benefit from spray foam.

Ultimately, spray foam represents an ideal way to enhance the building envelope, contributing to greater efficiency, longevity, integrity, and more. Adhesives and sealants professionals have the opportunity to advocate for its use in a wide variety of insulation applications — any structure stands to reap significant benefits.

To learn more about spray foam insulation and how to seize the benefits, visit www.HandiFoam.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!