System Combines Curing and Dispensing for Automated Fuel-Cell Sealing

The combination of innovative adhesives, fast curing, and state-of-the-art dispensing technology has created a new production process.

A new solution developed by DELO and DATRON enables the sealing of fuel cells to be carried out with a high degree of automation and precision. The companies report that the combination of DELO's fast curing liquid gasket and UV curing technology with DATRON's high-speed dispensing system significantly shortens cycle times and increases process reliability. These results happen both during manufacturing and in the subsequent operation of fuel cells.

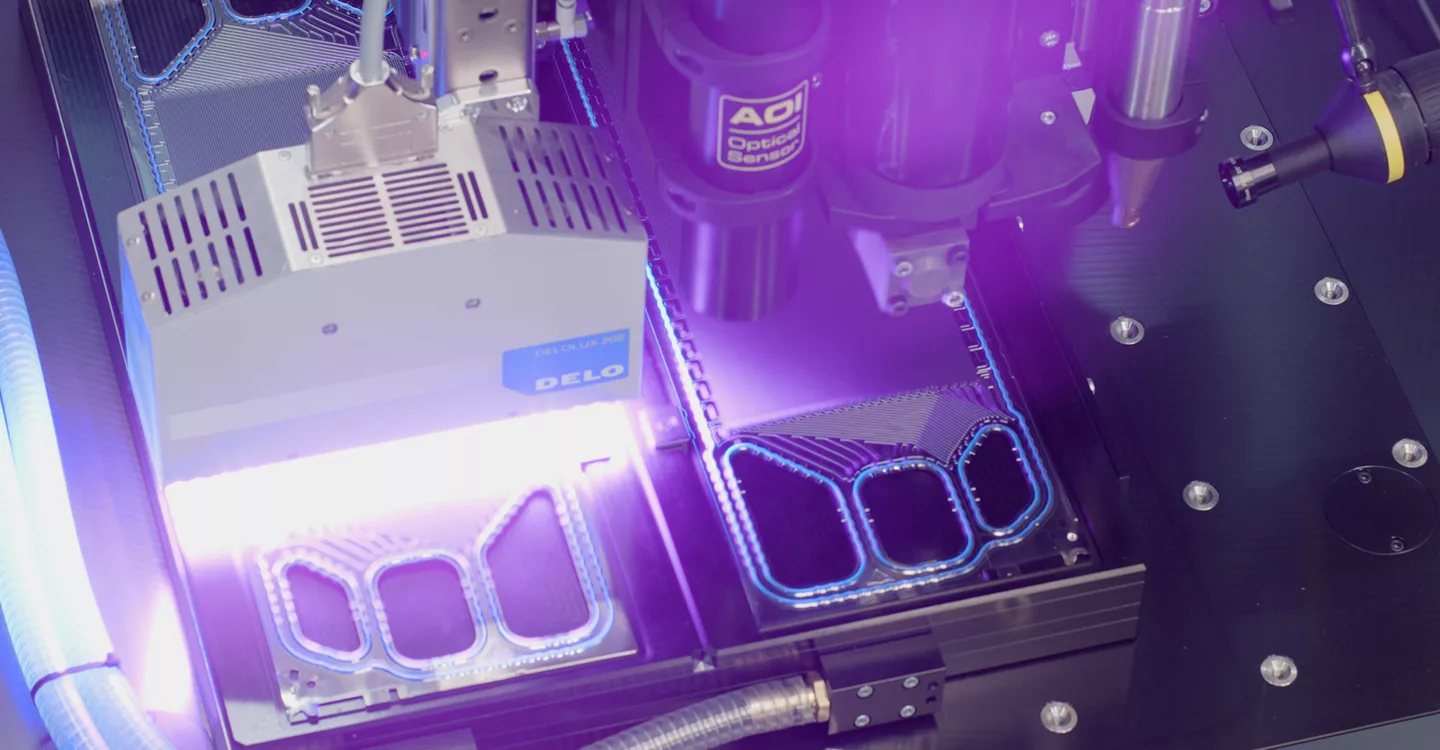

At the core of the solution is DELO PHOTOBOND SL, a liquid gasket material specifically developed for fuel cell applications. It is applied in liquid form and cured by light within just a few seconds. In addition to its short curing time, it offers high resistance to typical reference media such as sulfuric acid and deionized water, which is a key factor for the reliability and service life of modern fuel cells.

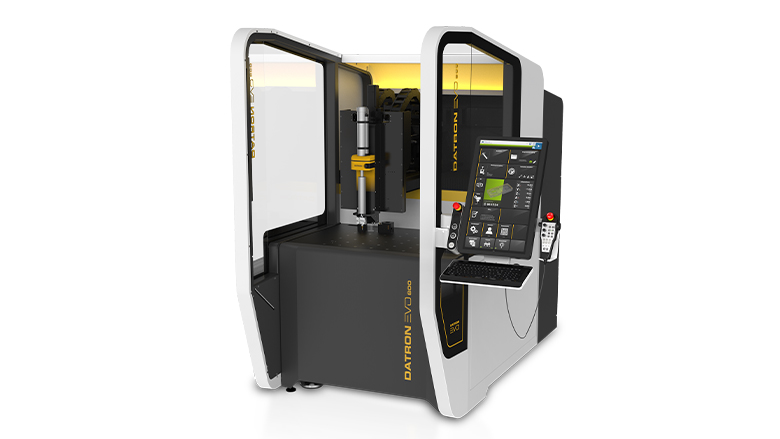

Precise application is ensured by the DATRON evo 600. The surface heights of the usually uneven bipolar plates are tracked by a high-precision path measuring field that is recorded with an optical confocal sensor before dispensing. This ensures consistent sealing on an uneven surface. Additionally, it achieves exceptionally high dispensing speeds of up to 50 meters per minute. The volumetric system guarantees a constant bead cross section, even at start and stop points. This makes it possible to produce hundreds of cells with consistently high quality that can then be reliably combined into a stack. The liquid application allows maximum design flexibility in gasket geometry and is ideally suited for automated production. Both the integrated confocal sensor, which measures the gasket height immediately after dispensing, and the adhesive’s fluorescence enable fast inline quality control. This allows errors to be detected early, which ensures a reliable process.

Stack Sealing

Representatives at DELO report that stack sealing is a key factor in fuel‑cell industrialization.

“Sealing the individual fuel cells is often an underestimated but decisive step in the entire stack manufacturing process. Only if absolute tightness is achieved can the system operate reliably over the long term,” said Julian Hopf, product manager, energy storage and conversion at DELO. “With the upcoming industrialization of fuel cell production, speed is equally essential – and this new system solution makes a major contribution to achieving it.”

The new manufacturing process developed by DELO and DATRON, by contrast, represents a highly scalable and future-proof alternative; it is ideal for the transition from small-scale to mass production. Up to now, sealing has typically relied on time consuming, complex, and energy intensive processes.

Learn more about DELO at www.delo-adhesives.com. Additional information about DATRON is available at www.datron.de.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!