Sealing Cell Module Controllers with the CIPG Process

During the production of battery sensors, highly viscous liquid sealants are used to protect these sensitive electronic components from external influences and temperature-related stress and physical shock and vibrations.

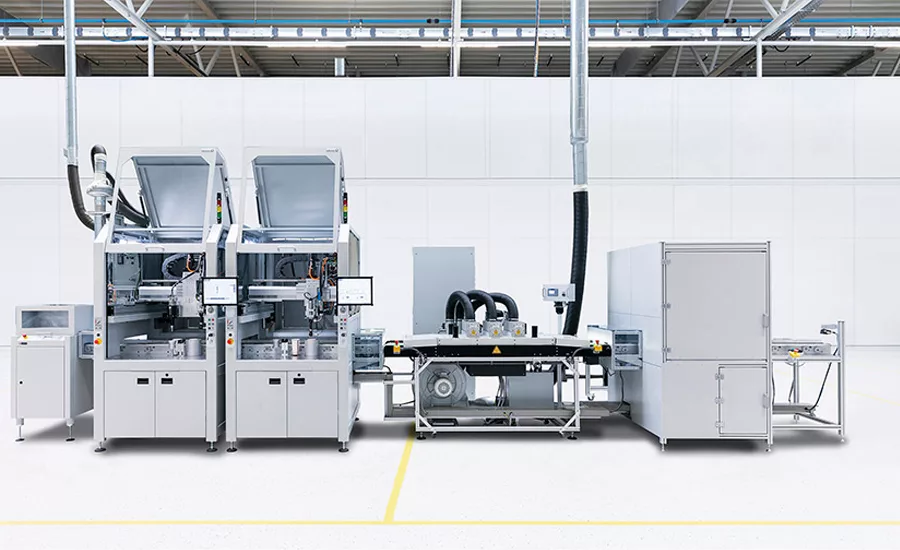

Dispensing system for sealing cell module controllers using the CIPG process. Image courtesy of Hönle.

Overview of process steps 1-4 of the dispensing system: Plasma (1), dispensing the contours inside (2) and outside (3), and UV curing (4). Images courtesy of Hönle/bdtronic.

In the final step, all parts undergo an optical inspection to ensure the quality of the seals. Images courtesy of Hönle/bdtronic.

With the goal of developing a flawless process solution for dispensing and curing liquid gaskets for cell module controllers, the system manufacturer and dispensing expert bdtronic and the UV expert Hönle have teamed up for a manufacturing process using the CPIG method.

Battery sensors play a crucial role in controlling and managing the performance and safety of electric vehicle batteries. They monitor parameters such as temperature, voltage, and current and report this information to the battery management system (BMS), which controls and monitors the battery's charging and discharging processes.

During the production of such battery sensors, highly viscous liquid sealants are used to protect these sensitive electronic components from external influences such as dust, road salt, and moisture, as well as temperature-related stress and physical shock and vibrations.

These liquid sealants are typically identified as cured-in-place gaskets (CIPG). A machine manufacturer for technologies that include dispensing, bdtronic supplies automated dispensing systems for CIPG applications. These systems can also incorporate modules for plasma pretreatment/surface treatment, UV curing, and camera inspection.

A recent collaboration between bdtronic and Hönle created an inline, five-step process for CIPG dispensing and curing. In the first step, the component contours are pretreated with atmospheric pressure plasma to achieve better adhesion of the sealant. In the second and third steps, the highly viscous CIPG is applied in contours. In the fourth step, curing is carried out using a Hönle UV curing system.

Step five involves the optical inspection of the finished part to ensure the highest level of quality and consistency.

Case Study

Battery sensors are usually produced by suppliers to the automotive industry. With the expectation of high-volume production, these TIER 1 suppliers typically approach the engineering company with specific target requirements. Fabian Tremmel, head of Engineering Dispensing at bdtronic, explained, "To achieve the best possible process, it is essential to work closely with the customer and all involved technology providers from the very beginning. We need to understand the requirements and collaboratively develop their technical implementation."

For this specific cell module controller project, the customer specified the following parameters:

- Production volume: 6,000 battery sensors / 24 hours => 1 part every 13 seconds

- Material (metal) and shape of the part

- One-component sealing compound

One of the keys to an efficient and reliable manufacturing process is the interaction between the sealing compound and the UV curing device. Questions to be addressed include:

- At what wavelength is the polymerization of the sealing compound triggered?

- How long and with what intensity should the exposure be to achieve complete curing?

Extensive laboratory tests are indispensable to align these parameters.

This is one of the reasons why bdtronic had once again chosen to cooperate with UV specialist Hönle for this project. Hönle, is a global leader in the UV/LED curing of adhesives, sealants, printing inks, and coatings, as well as providing UV sterilization systems for purifying water, air, and various product surfaces. Hönle has its own application laboratory and is capable of performing extensive curing testing with photoreactive materials. "At Hönle, we strive to always find the best possible solution for our customers' processes. Our decades of experience in UV curing and our uniquely extensive portfolio of LED-UV and UV systems allow us to quickly find the optimal solution for the customer," said Mina Kamal, sales engineer at Hönle.

Achieving an optimal curing result requires accurate selection of suitable UV ranges, intensity, and dose. Hönle’s testing quickly revealed that the sealing compound used in this application polymerized in the broadband spectrum of UVA and UVC, and required an unusually high UV dose. The Hönle UVAPRINT curing module was identified as the optimal curing system for this material. With its Cold-Mirror technology, the UVAPRIINT system ensured that the temperature on the substrate did not get too high despite the extremely high intensity. In the production process, the components pass through three consecutively installed UVAPRINT modules, which provide a full cure before the sensors move to step five for optical inspection.

The customer now has a production line that allows for process and planning security, delivering a high-quality battery sensor seal every 13 seconds — a small but significant component on the path to e-mobility.

Learn more about Hönle at www.hoenle.com. Learn more about bdtronic at www.bdtronic.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!