Innovative Process for Sealing Contours Protects Sensitive Components

New dispensing processes allow for more precise application of liquid seals in assembly of automotive components.

zhongguo / Creatas Video via Getty Images

Liquid seals in the automotive industry have to meet high functional quality standards and have to be applied in the shortest time possible due to the high volume of work pieces. This market environment gives rise to innovations that guarantee maximum speed and quality from initial design to final results.

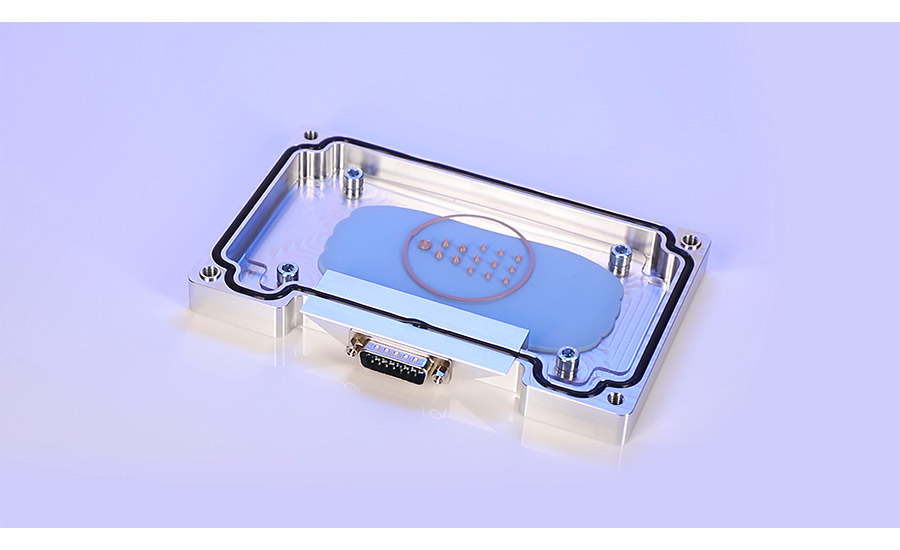

When dispensing liquid seals, for example on the housings of automotive control units, it is particularly important to apply the material precisely each and every time along the intended sealing contour. On the die-cast housing, the sealing contour runs partly in a straight groove, partly around corners and screw locations, and partly in various radiuses. For the area where the plug housing will later be installed, the liquid seal often has to be applied on ramps.

Perfect Sealing Contours

Once the seal contour has been optimized to fit the component and has been created in CAD at the workstation, it is transferred to a storage medium and can then be passed directly to the system, making data import very simple. The Upic5 editor enters the DXF file for the CAD contour directly and automatically generates the NC block. Application of the seal contour can then start immediately.

Easily import data: Just enter the CAD contour in the Upic5 editor.

Adaptive Dispensing Speed

To ensure that the material is applied evenly, the dispensing speed must be adjusted to the current contour section. Scheugenpflug’s new software function allows the dispensing speed to be adapted to the axle speed. The axis system accelerates on straight sections, so the application speed is automatically increased at the same time. Along tight radiuses, the simultaneous reduction of the axis speed and the dispensing speed prevents material from accumulating. The process time can be significantly reduced as a result of this direct link. In some applications, it is reduced by up to 50 percent.

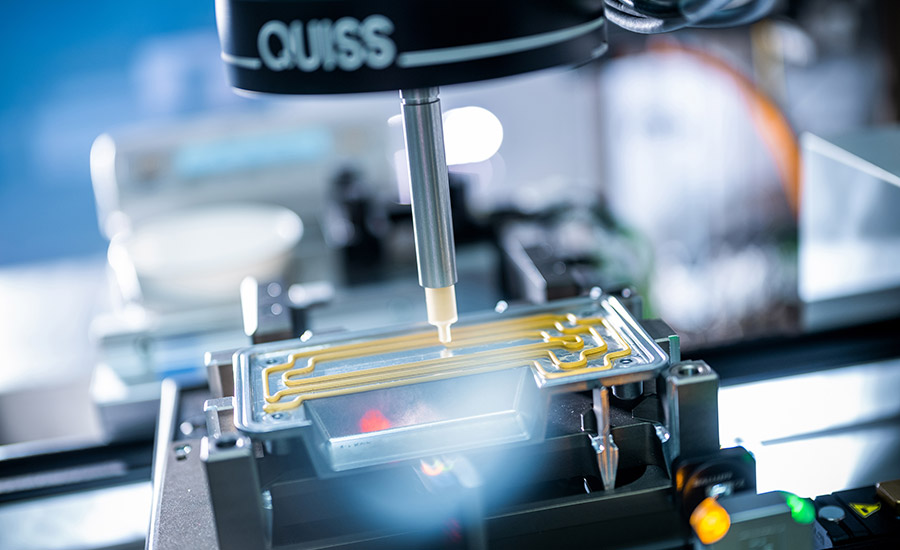

Precise and homogeneous application of material even for tight radiuses and/or complex geometries.

Real-time Inspection

Only those material applications that have been fully and reliably tested meet the high safety standards demanded by the automotive industry. By integrating inspection in the dispensing cell, Scheugenpflug in conjunction with Atlas Copco has added yet another important automation step. To ensure optimum proven and traceable product quality, vision systems are used to check the width, position, and uninterrupted application of the adhesive or sealant during application itself. The quality of application is known as soon as the adhesive or sealant has been applied. Therefore, there is no need for a separate cell, which means that users save on cycle times and resources.

The sensors are mounted directly on the application head above the nozzle. Inspection is performed in real time as the adhesive or sealant is applied, so the plant personnel know immediately whether this is “IO” or “NIO.”

Inspection with RTVision is available in 2D and 3D. The version with 2D sensors uses an LED light source as the incident light to detect the width and continuity of the application by contrasting the adhesive bead with the background. RTVision 3D uses six lasers as the light sources to evaluate the third dimension, namely height, as well.

Users benefit from the user-friendly software because the parameters are easy to set and the software indicates a clear OK/NOK. Detailed visualization means that the status is instantly visible.

By integrating inspection in the dispensing cell, the application is tested and monitored at the same time as the adhesive or sealant is applied.

By integrating inspection in the dispensing cell, the application is tested and monitored at the same time as the adhesive or sealant is applied.

Tried and Tested

In response to a request by a major automotive supplier, Scheugenpflug recently set up a further automated assembly line for a control unit to be used in electromobility. The requirements for a compact line layout and a cycle time of less than 30 seconds were achieved by combining adaptive dispensing speed with real-time inspection within the dispensing cells.

In the first process cell on the assembly line, heat-conductive adhesive is applied to the die-cast housing along a meander contour using a robust, high-precision dispensing head and tested simultaneously with RTVision 2D. The position of the bead and its width can be accurately monitored to +/- 0.2 mm. A silicone seal is then applied to the housing, first in the area of the recess for the plug housing. The necessary ramps are achieved with a gear dispensing head with integrated swivel needle. RTVision 3D determines the position, width, and height of the seal and any possible interruptions with zero time offset. After the PCB has been joined to the plug housing; automatic screwing is then completed, and another silicone seal is placed in the surrounding housing groove and over the plug housing. At the end of the dispensing process, the material is sucked back from the gear dispensing head to ensure a perfect end to the bead. The liquid seal is once again inspected with RTVision 3D. The position of the bead and its width can be accurately monitored to a tolerance of +/- 0.1 mm. Height discrepancies of more than +/- 0.15 mm can be detected. Finally, the top is added and connected by a crimping process.

Competence Right down the Line

All steps are implemented in an automated production line: dispensing, sealing, screwing, crimping, and testing. The result is an all-in-one solution with full integration of 2D and 3D inspection in the dispensing cell.

The current trends and challenges in the electronics sector call for new and sustainable dispensing and potting solutions. From the simple import of the DXF contour right up to the final inspection of the applied sealant in real time, there has never been an easier or quicker way to achieve the perfect sealing. Together with its network of partners, Scheugenpflug is pushing ahead with innovations that meet high demands in terms of precision and productivity, especially for automotive solutions.

For more information, visit www.scheugenpflug-usa.com.

All article images courtesy of Scheugenpflug GmbH.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!