New Research Investigates Innovative Possibilities for Process Monitoring of Sealants

Inline-capable measuring techniques should enable quality assurance of applied sealants in the future.

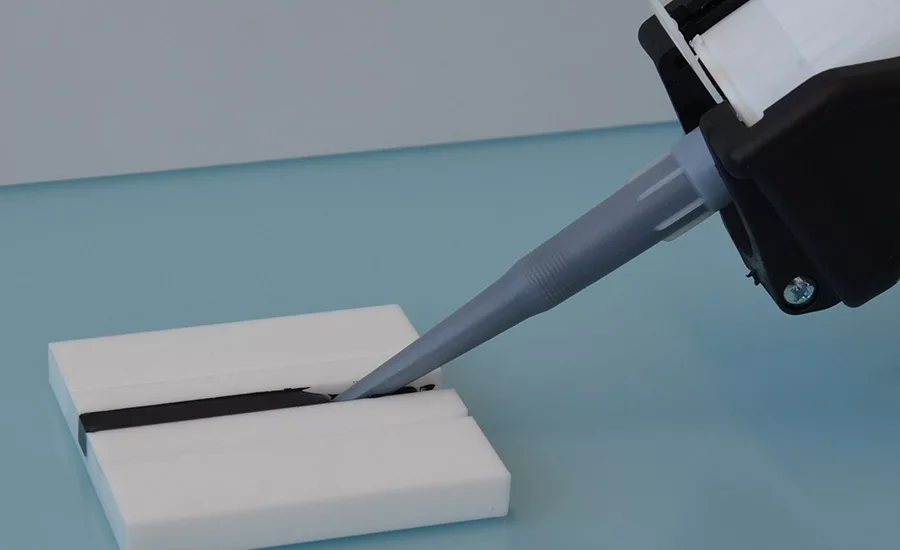

Application of a sealant in a test specimen. Photo courtesy of Daniel Hoffmann of SKZ.

A new IGF research project, SteP-in, is being conducted with the SKZ Plastics Center and the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM where these entities are using several non-destructive testing methods to advance the quality assurance of sealing compounds. Modern techniques such as air ultrasound and optical profilometry are used to determine the curing progress inline and AI-based curing models are developed. Air inclusions and other defects are to be detected using a new thermography technique.

Inline-Capable Measuring Techniques

Due to their comprehensive functions, sealants have many areas of use, from everyday applications in the home to high-performance applications in the aerospace industry. During application, the curing time specified by the manufacturer is often used and a safety factor is applied or in-process measurements are carried out on separate samples. The additional effort or unnecessarily long holding times before the next process steps are accepted.

Airborne Ultrasound and Optical Profilometry

To enable a more efficient process, the SKZ and Fraunhofer IFAM scientists are currently researching non-contact testing methods that can be used to determine the curing progress inline. Air-coupled ultrasound, or air ultrasound for short, and optical profilometry are being used for this purpose. Air ultrasound can be used to determine changes in the density or elastic properties of the sealant, while optical profilometry can measure shrinkage during curing with a resolution in the µm range.

Training AI

The measured variables, together with other influencing factors such as ambient temperature and humidity, are to be used to train an artificial intelligence (AI) program. This will enable curing models to be developed that can be used to reliably determine the progress of curing. Various sealants and different joint shapes are to be investigated in order to design the methods for industrial application. In the further course of the project, the measurement methods will also be tested on real components.

Detection of Typical Defects

Another part of the research project is to develop a measuring method that can be used to detect typical defects such as air inclusions or detachments in the seals. Such defects are usually not noticeable during a visual inspection, but can significantly limit the performance of the application or even lead to a safety risk. A measurement approach based on active thermography, in which the component is periodically heated with several flashes of light, is being further developed for this purpose.

Search for Interested Companies

Interested companies can participate in the project free of charge and without obligation as part of a project support committee and thus gain first-hand pre-competitive research results. There is also the opportunity to test the measurement techniques on the individual products of the companies on the project committee. In this way, interested companies can directly assess the suitability of the inline-capable methods for themselves.

Learn more about the research project studying non-destructive testing.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!