AI, Machine Learning, and 3D Vision Will Revolutionize Dispensing

Artificial intelligence, machine learning, and 3D computer vision technology will revolutionize how the dispensing of adhesives and sealants is performed.

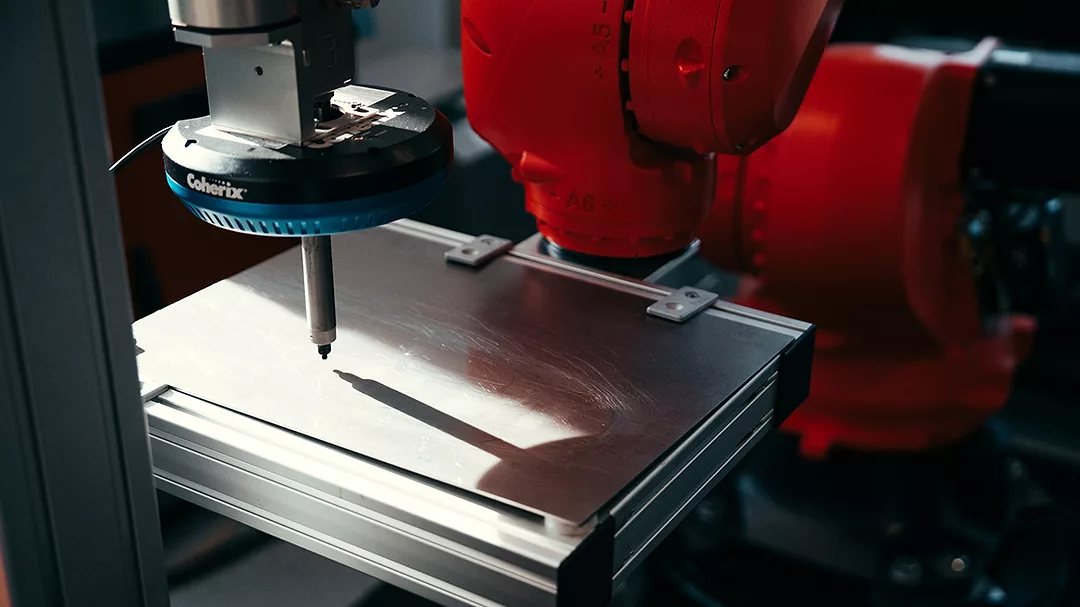

The 3D process control inspection system automatically adjusts nozzle position to correct bead placement without stopping production.

When teamed with a laser-based 3D computer vision system, AI and machine learning can dramatically increase assembly-line throughput and reduce scrap.

By mounting around the dispensing nozzle, the 3D sensor captures a complete 360° view of the bead in any dispensing direction.

When teamed with a laser-based 3D computer vision system, AI and machine learning can dramatically increase assembly-line throughput and reduce scrap while improving overall product quality, even with the smallest components used in cars, cell phones, consumer electronics, and medical devices. Potential cost savings in the U.S. alone could top tens of millions of dollars annually.

Robotic adhesive-dispensing systems equipped with 3D sensing and process-control software will allow for automatic adjustment of the volume and location of the dispensed bead, all without the need to shut down or slow an assembly line. When inspection is completed inline, the need for additional fixturing and floor space also is eliminated.

In the past, computer vision systems were used to detect defects and sort them from the good parts, which is called inspection. With inspection, accuracy is very important because one micron outside of the control limit will cause the part to be rejected. However, dispensing is a continuous process that requires controlling the mean of the volume dispensed, centered between the lower and upper control limits, to ensure the process never produces a bad part.

A 3D computer-vision system combined with AI-driven process control continuously collects data and adjusts the dispensing process to keep volume and material placement centered between upper and lower control limits, preventing bad parts from ever being produced. If a random event occurs like a gap in the bead caused by air getting into the hose, for example, AI can take control of the robot and dispensing machine to fill the gap before moving on to the next part.

Nearly 8,000 automated dispensing systems are produced annually for use in the automotive industry. More than half of those systems could benefit from 3D process-control technology. The electronics industry is even larger. More than 30,000 new automated dispensing systems are installed on assembly lines for electronic products each year, with more than 30 percent suitable for improvement with AI and machine-learning technology.

Coherix economists estimate that the global market for adhesive dispensing systems used to assemble extremely small automotive, consumer electronics, and medical-equipment components alone totals more than $500 million with an annual growth rate of seven to 10 percent.

Today there is an ever-growing demand for consumer electronics products that contain hundreds of extremely small components that require the precise application of adhesives. Cars, light trucks, and heavy-duty vehicles are now essentially computers-on-wheels, making sealants and adhesives more critical than ever.

Recently developed 3D laser-based computer vision allows manufacturing engineers to check the application of adhesive beads as small as two human hairs in width at speeds up to 1,000 times per second. When equipped with AI and machine-learning algorithms, the new technology also can adjust the dispensing of adhesives to ensure near zero defect rates.

There’s vast potential for improvement, offering equally significant opportunities to reduce costs. Often, the application of adhesives is checked on just one in every 500 parts, leading to costly assembly line shutdowns and quality issues. Problems can include bent nozzles caused by part-to-part variation and air bubbles in hoses that cause gaps in dispensed beads.

AI-Assisted 3D Process Control

AI-assisted 3D process-control systems allow manufacturers to monitor dispensing in real time and automatically make adjustments, all without slowing down production lines. In the past, 2D vision systems were commonly used to inspect adhesive beads; however, a transition to 3D will be essential to taking full advantage of AI and machine learning technology. 2D vision systems cannot capture depth for critical height and volume measurements and become ineffective when the dispensed material is the same color as the part.

Automated dispensing systems require vision to perform optimally. Some dispensing systems can tell how much total adhesive is dispensed but are unable to “see” where the material was actually applied. A robot could follow its programmed path and dispense adhesive even when the part isn’t present, causing the material to be dispensed onto the plant floor instead of the part.

3D computer vision systems give manufacturing management data needed to analyze process variation over time. They are able to verify that dispensing systems consistently apply the correct volume of material in the correct location on each part.

In the 3D laser-based process-control system developed by Coherix, four high-speed 3D sensors are mounted around the dispensing nozzle to provide a 360-degree view of adhesive beads in any dispensing direction, without added complexity to robot programming.

Using 3D computer vision data, AI can continually adjust the application of adhesives to meet specifications during every dispensing cycle. If a gap occurs, AI can take control of the robot to fill the gap before it moves on to the next part. AI software can make adjustments to overcome part-to-part variation, ending manual robot path adjustments every time a new lot of parts arrive as well.

With the application of urethane on glass in a manufacturing plant, for example, temperatures will change throughout the day — cold in the morning and hot in the afternoon. Temperature changes may cause the glass to shift, which can result in urethane beads being applied in the wrong location and the need to stop the assembly line and re-program the robot path. Inline 3D computer vision enables automatic adjustment of the nozzle’s height and lateral position relative to the glass edge, eliminating the need for robot path re-programming and associated downtime.

Several process-control software packages are currently available on the market, including:

- An auto-repair program that repairs gaps and other low-volume adhesive issues by automatically re-running the robot path and dispensing material only where low volume was detected.

- Lateral and Z tracking systems that automatically adjust nozzle positions in real time to compensate for part-to-part variation. If these variations are left untouched, they cause expensive dispensing nozzles to break or bend, increase scrap, and deliver poor product quality.

- Auto-locate software that adjusts the application of sealants and adhesives on improperly fixtured or positioned parts. The technology cuts back on the need for expensive fixturing systems and reduces unscheduled downtime.

- 3D nozzle quality-control software that alerts operators of bent or misaligned dispensing nozzles, a common problem that results in incorrect bead location and unplanned downtime.

AI and computer-vision systems already have had a major impact on assembly lines around the world, but the technology only recently has been used to improve the performance of adhesive dispensing systems.

A major automaker, for example, combined 3D Z tracking and auto-repair software programs to reduce unscheduled downtime at an assembly plant by five hours per week with substantial reductions in scrap and re-work costs.

Another OEM saved over $450,000 per week in downtime by using 3D process-control software to prevent dispensing nozzle breaks on an assembly line sealing battery-pack cases that had significant part-to-part variation.

In more general terms, artificial intelligence with supporting 3D computer vision has proven to reduce adhesive use by up to 30 percent along with savings of 25 percent or more in overall labor costs while reducing vehicle weight.

3D computer-vision systems also are relatively easy to install. A system to inspect adhesive application on fast-moving assembly lines took just one day to install. Less than two days of training were needed before assembly-line and quality-control employees could use the system.

Rising demand for adhesives and sealants in electronics manufacturing is driving the need for advanced 3D inspection technology to ensure precise volume, accuracy, and quality in material application.

Coherix recognized the importance of 3D computer vision technology, artificial intelligence, and machine learning in the application of adhesives and sealants quite some time ago.

The company has invested over $100 million and more than one-million engineering hours in the development of its 3D laser-based inspection and adaptive process-control technology, and has over 5,000 systems installed globally. There currently are more than 40 engineers and product development specialists dedicated to further improving Coherix inspection technology, and the company has just recently opened a new product innovation center to continue the development of industry-first software systems.

Learn more about Coherix at www.coherix.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!