AI-Driven 3D Vision Revolutionizes Adhesive Dispensing Quality Control

As electronics get smaller, manufacturers are turning to AI-powered vision systems to apply adhesives with pinpoint precision.

Manufacturing today’s tech-heavy vehicles, consumer electronics and medical devices that contain hundreds of extremely small components require the precise application of adhesives and sealants.

Those strict guidelines are being met by new, recently developed, 3D laser-based technology capable of giving manufacturers the ability to check the application of adhesive beads as small as two human hairs in width at speeds of 400, up to 1,000 times per second.

The new technology provides the key to ensuring quality, safety, weight, and cost savings, by monitoring and adjusting how those critical substances are being applied before products reach end users.

Indeed, in the electronics and automotive industries, there's a significant amount of adhesives used in everything from smart phones to ear buds to computers to electronic control units (ECUs). Many of the components in these devices are already small, but the tiny elements inside them increase the challenge of precisely applying adhesives to those parts in volume and dimension.

Coherix estimates the global market for adhesive inspection systems for small parts on high-speed assembly lines at more than $300 million annually and expects it to grow 7 percent or more over the next 5-10 years. The consumer electronics industry alone is expected to install more than 30,000 new adhesive dispensing systems in the next year.

China’s rapidly expanding production of electric vehicles and other electronic products makes it the single largest potential market for this new technology. Europe also is an attractive market because of the large number of dispensing and robotics companies located there. In North America, Mexico is emerging as an attractive market as well.

In automotive, where vehicles have basically become rolling computers, sealants and adhesives play a major role in the production of a myriad of electronic components.

The accuracy of sealant and adhesive application is becoming increasingly important in the auto industry as carmakers move toward more electrification, autonomous driving systems, and more sophisticated infotainment systems, requiring smaller and lighter components.

According to the Adhesives and Sealant Council, the adhesives and sealant industry in North America alone is responsible for more than 28,500 manufacturing jobs with payroll in excess of $1 billion. An estimated 10.3 million pounds of adhesives and sealants valued at more than $22 billion were produced in North America in 2022, the latest year for which figures are available.

The issue lies in the fact that modern inline inspection systems inspect just one in every 500 parts for proper adhesive application. Such infrequent inspections can result in costly assembly line shutdowns and quality-control problems. Those problems include air in the pump causing bursts, clogged nozzles blocking adhesive application and simply too much or too little adhesive.

3D laser-based inspection systems equipped with machine-learning, artificial intelligence and adaptive process-control software now are catching those issues more often and much more quickly, even in the smallest components.

In addition, these new inspection systems allow manufacturers to inspect and automatically adjust dispensing processes without slowing or shutting down production lines.

The new technology is capable of measuring height, width, volume and location, providing vital data needed to optimize dispensing processes for micro-bead geometries from 0.2 – 3.5mm.

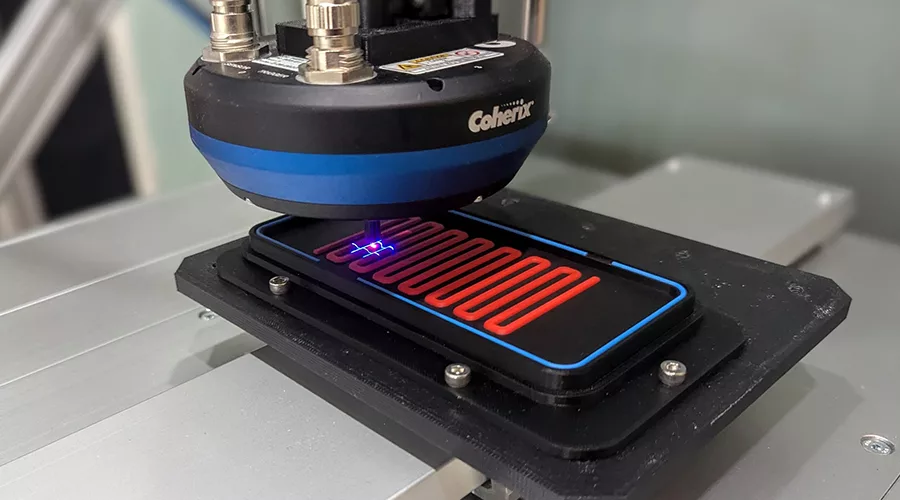

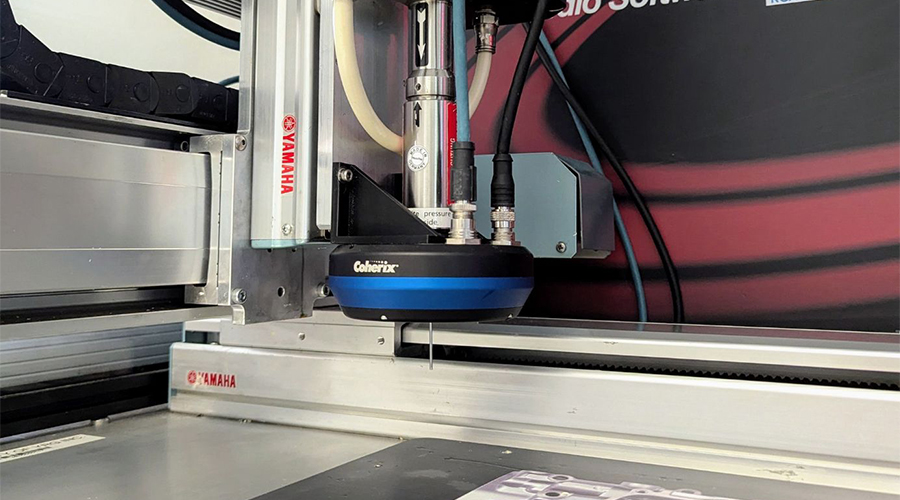

The Coherix 3D mini-bead inspection system is mounted around the dispensing nozzle and equipped with four high-speed 3D sensors that provide a 360-degree view of the bead in any dispensing direction with no added complexity to robot programming.

A near-zero defect rate is achieved when 3D inspection systems are equipped with process-control software that monitors and adjusts the application of adhesives to ensure that every part meets specifications.

There’s a growing need to quickly and accurately monitor and adjust the application of adhesives as manufacturers respond to major changes in the automotive and consumer electronics industries, according to Ivy Nguyen, a manufacturing expert and principal at venture capital firm Autotech Ventures.

Nguyen points out assembly lines were typically set up to repeat a process two or three million times before they would need to be reconfigured or dismantled to produce another component.

She says two important things have changed:

- First, in today’s era of mass customization, manufacturers offer limited editions that often require numerous production adjustments.

- Market volatility is second factor. If an automaker, for example, projects selling two million units of a new EV model but sales are much softer, production must be quickly adjusted.

"Humans know how to adjust to that on the fly, whereas a machine may have to be trained on thousands, if not hundreds of thousands, millions, of examples of what to do," Nguyen says. "So even making those micro adjustments, AI has made it possible to make those micro adjustments on the fly, I think, much more successfully than a machine designed in the 1980s might be able to do.

"But at the same time, if you need to make larger changes on how the glue is applied, you probably have to come in and rewrite some of the programs a bit and retrain the models a bit, in order to get it to work successfully."

Now, in the case of newer 3D laser-based inspection processes, artificial intelligence plays a key role in detecting and adjusting for changes, which is especially critical in the case of very small electronic components.

Using data collected by computer vision, AI methods continually adjust the application of adhesives to meet specifications on every dispensing cycle. For example, if a gap is missed on the original cycle, AI can take control of the robot to fill the gap before moving on to the next part, resulting in significant savings in labor and scrap costs.

With real-time feedback from a 3D vision system, AI software also can make adjustments to overcome part-to-part variation. The system, for example, can detect waviness in a part that was not programmed in the original robot path, then calculate and send adjustments to the robot on-the-fly.

The Coherix 3D system uses machine vision, also referred to as computer vision. When used correctly, engineers can view and record whether adhesive has been properly applied, ensuring dispensed material meets width, height, location and volume specifications.

The system is cost effective as well. In a recent beta test with a major manufacturer of electronic control units for the auto industry, assembly-line costs were reduced by 20 percent. In that test, the company estimated annual savings of up to $160,000 in operating costs from the installation of just eight, 360-degree inspection sensors on one assembly line. Despite its complexity, the technology is easy to install and use.

In one example, a 3D computer-vision system installed to check adhesive application on fast-moving assembly lines for extremely small parts took just one day to install. Less than two days of onsite training were required before assembly-line and quality-control employees could use the innovative technology.

More traditional 2D inspection systems currently in use fall short on the job in several ways. For one, they are unable to measure volume, a critical measurement in the dispensing process. Secondly, many 2D systems only inspect after adhesives are applied — what’s known as a "post-inspection" quality check.

Floor space is always at a premium at factories, and 2D systems require a considerable amount for lighting rigs, cameras, fixtures, and other equipment. In addition, 2D vision is unable to understand the difference between a part and an adhesive bead when the colors of the part and the adhesive are relatively similar since cameras can’t pick up contrast between the two.

Robots are problematic as well. They require some form of “vision” to operate optimally. For example, some dispensers are able to show the volume of adhesive applied but can’t indicate where it was applied. A robot may run a programmed path and simply dispense adhesive regardless of whether or not a part is actually present. If a part is moved or improperly placed, the material also might be dispensed in the wrong place or on the floor for that matter. A laser-based 3D inspection system equipped with computer vision and adaptive process control technology eliminates those issues.

A 3D system provides manufacturing engineers with data needed to evaluate the performance of the dispensing process, allowing engineers to view and record whether adhesive has been properly applied. 3D vision technology also can ensure that the dispensed material meets width, height, location and volume specifications.

These are important capabilities for any manufacturing task but are absolutely critical for the precise application of adhesives required for producing miniscule-sized elements in small electronic products.

Floor space considerations are handled by the fact that 3D inspection systems are inline, eliminating the need for additional space on the factory floor. With 3D vision, part- and material-color can be the same without affecting accurate volume measurements. It also can detect if a dispensed bead meets height and volume specifications.

As the electrification of autos and other consumer products has grown, so has the market for adhesive-dispensing systems with advanced inspection technology.

Increased demand for adhesives and sealants in the production of small electronic components also will increase demand for the latest 3D inspection technology to ensure those materials are applied with precise volume, accuracy and quality.

For additional information about Coherix and its technologies, visit coherix.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!