Dynamic UV Monitoring Enhances Performance of Hot-Melt Adhesives

Collaborative development with ICAD Technology is helping to develop more robust, sustainable, and high-performing UV adhesive solutions.

The adhesives and sealants industry is driven by need to provide customers with products that improve manufacturing processes and offer stronger and more sustainable bonding. While traditional hot-melt adhesives can rely on cooling to achieve initial bond strength, advanced chemistries and UV-curable systems require a secondary, controlled curing step to achieve bonding. Among the options adhesive manufacturers have at their disposal, as they develop products and curing processes, is a technology that moves beyond static, pre-set curing parameters to enable real-time information about the curing environment as the product moves down the line.

Inline continuous automated dynamic (ICAD®) Technology helps to improve UV technology quality in production by sampling different wavelengths in real time. A sampling rod that travels in the area between the lamp/LED and the substrate to be irradiated, ICAD Technology can detect variances in light output, which can change the quality of the substrate. With applications ranging from process control to R&D, ICAD can be used to detect problems in real time as well as help to develop consistent parameters during the development process.

This technology is now being used as a key component for enhancing precision and efficiency in Henkel's UV hotmelt processes. According to Henkel, the technology ensures continuous inline monitoring and control of UV exposure, establishing a shared "UV language" between manufactures and customers, that enhances process stability and production efficiency.

Because precise UV exposure plays a critical role in achieving optimal performance for UV hotmelts, Henkel has incorporated the technology into its development processes, both in the laboratory and on pilot lines. With a real-time monitoring solution that accurately defines UV requirements, ICAD provides absolute radiometry and continuous process control, ensuring constant quality.

Traditional UV measuring devices have been widely used for defining dose and irradiance. However, these are impossible to pass through a roll-to-roll process, and therefore UV exposure has been a guess work in these applications, with production challenges as a result. With ICAD Technology, Henkel is able to monitor and define the UV output inline. The information enables the company to guide users of hotmelt products to mirror these settings and thereby increase production yield and quality.

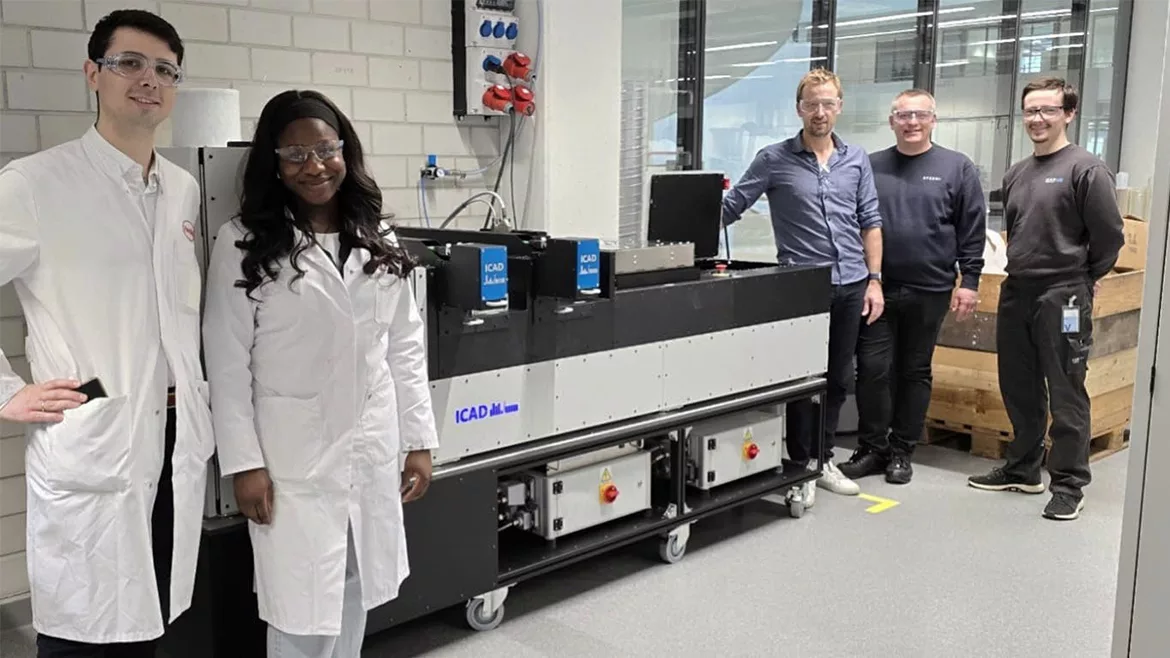

As part of this process, the company has an ICAD Test Bench at its Inspiration Center Düsseldorf in Düsseldorf, Germany. The test bench simulates real production conditions to refine UV hotmelt curing processes. Included at the facility is an IR station from Excelitas Technologies, which is placed before the UV or UV-LED system and allows the UV hotmelt adhesives to reach production-like temperatures. An integrated high-speed conveyor system supports laboratory testing at speeds of up to 250 m/min, enabling production setup within in the R&D phase.

"By integrating ICAD Technology into our development processes, we are enhancing our ability to ensure precise and consistent UV exposure in hotmelt/psa applications," said Dr. Stefan Mundt, global technical lead UV Hotmelt-PSA at Henkel. "The collaboration with ICAD Technologies enables us to further refine our adhesive solutions and provide customers with superior performance and reliability."

Learn more about ICAD Technology at https://icad-technology.com. Additional information from Henkel is available at www.henkel.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!