Electrically Conductive Adhesives Get Smaller

Electrically conductive adhesives are utilized in all types of electronic devices and may be found in most microelectronic assemblies and integrated circuits. Conductive epoxies are used for bonding in capacitors, semiconductors, transistors, diodes, rectifiers and thermistors.

These adhesives serve two basic functions: they provide bonding tailored to specific applications and operating conditions, and they create a conductive path between the two surfaces being bonded. Beyond these two criteria are a host of additional requirements. The epoxy resin and conductive filler must both be chosen with these requirements in mind.

As electronics are reduced in size to lower power consumption and cost, conductive adhesives must parallel this trend toward the small. New work in nanotechnology is a sign of the ultimate goal of electronics manufacturers, namely to produce atomic-scale electrical components. Traditional conductive epoxies are inadequate for such a small scale, but new developments in this field are helping electronics to shrink.

Electrically conductive epoxies utilize traditional epoxy-adhesive resin matrices but incorporate conductive elements to facilitate electrical connections. Most epoxies require heat to cure but will set or cure at room temperature given enough time. The conductivity of a material is typically reported as a readily measured inverse property, resistivity.

Choice of Conductive Materials

A variety of conductive elements are available to the compounder. Carbon black and antimony oxide are two well-known materials that afford moderate resistivity values. New materials on the market include fibers that are coated with conductive media. These non-metallic conductors see limited use in conductive-adhesive applications due to the amounts required to achieve satisfactory conductivity and ease of handling.More typical choices for conductive adhesives are metal fillers. While metals as a group exhibit high electrical conductivity, common metals such as nickel and copper are rarely chosen because of their susceptibility to oxidation. Precious metals such as silver and gold are the conductive elements of choice due to their stability and effectiveness.

It is possible for silver and gold epoxies to achieve resistivities of 1 x 10-3 to 1 x 10-4 ohm-cm (the lower the resistivity the greater the conductivity). Silver is most commonly employed due to its cost advantage over gold. In some devices, silver migration may be a problem, and, for these applications, gold is chosen.

Electrical conductivity is a way of describing the movement of electrons, and thus it is necessary for good contact throughout the matrix. Spherical metal particles do not pack closely enough in a resin matrix to provide optimum surface-area contact, detracting from electrical conductivity. Instead, metals in flake form are utilized. In the matrix, the metal flakes pack closely to one another in a parallel orientation, facilitating the passage of electrons.

Typical Properties of Conductive Adhesives

What are the typical properties of conductive epoxies? Those looking for conductive adhesives will first consider the conductivity as previously described, but there are many other requirements in both the uncured and cured states.Important considerations in choosing a conductive adhesive are shelf life, pot life, viscosity, one- or two-part system, cure time, and cure temperature. These properties represent handling issues and must be evaluated carefully, depending on the process and personnel involved in the use of the material. The chemistry of the epoxy resin, hardening agent and accelerator all affect the physical properties of the adhesive in both the uncured and cured states.

Physical requirements of the cured adhesive are dependent on the end use and are derived from the conductive element or the epoxy resin itself. In addition to electrical conductivity, thermal conductivity is another crucial factor. Heat generated during the operation of electronic devices may need to be isolated or transferred, and the adhesive itself may be called upon to insulate or transmit heat.

Low-outgassing characteristics are often important factors, particularly when an adhesive is used in a reduced-pressure (vacuum) environment. Heat or even ambient temperature can contribute to outgassing of volatile components under vacuum, so it is important to choose the adhesive appropriately. Curing the adhesive at as high a temperature as the overall device will tolerate can reduce outgassing.

Bond strength and shrinkage are related properties. Adhesives are meant to bond two surfaces together, and epoxies must therefore bond adequately. The electronics industry utilizes a broad range of materials including polymeric, ceramic and metallic. Substrates may be smooth, flat surfaces or rough, irregularly shaped parts. Not all epoxies will bond to all substrates, and care must be taken to choose an epoxy with the right bonding properties. Low shrinkage is desirable. All thermoset materials such as epoxy shrink to a small degree upon curing. If an adhesive shrinks too much, the bond may fail at one or both surfaces.

Electronics manufacturers demand high purity and low corrosivity from device components, and epoxies must have very low concentrations of extractable ionics such as sodium, potassium and chloride. Impurities can drastically affect the performance of electrical devices and so must be minimized. Moreover, epoxies sometimes exhibit an inherent chemical corrosivity or may contribute to electrolytic corrosion of metal parts (carbon black is a strong contributor to electrolytic corrosion), and these tendencies must be considered during the design process.

New Technology Measured in Nanometers

New technology in the electronics field is focusing on electrical devices on the atomic scale. Future generations of electronics will contain assemblies whose components are measured not in millimeters but in nanometers (one billionth of one meter). Researchers are now regularly reporting firsts (nanocircuits, nanowires and nanodevices) in scientific journals. Reducing electronics to an atomic scale also reduces weight, packaging materials, heat generation, size and cost. Alternatively, the use of smaller components allows manufacturers to include more features into existing devices without increasing device size.At the center of this research are materials called nanotubes. Nanotubes are hollow cylinders often with electrical properties of their own.

In some cases, nanotubes are doped with conductive atoms to attain desired properties. These dopant atoms reside within the tube, imparting a unique pathway to conductivity.

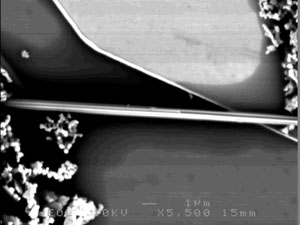

Single-walled carbon nanotubes (SWCN) and tungsten disulfide nanotubes are two of the more promising candidates in this field. With diameters in the 10- to 300-nanometer (nm) range and lengths of several microns (one micron = one millionth of one meter), nanotubes require special adhesives. Whether doped or not, these tiny materials have the potential to replace conventional circuitry and electronic components. Scientists are now learning how to manipulate nanotubes by cutting, bending and attaching them.

As an example, a researcher hoping to connect one end of a nanotube to a surface in order to measure conductivity requires an electrically conductive adhesive. A traditional silver-filled epoxy contains silver flake with dimensions anywhere from 10 microns to 30 microns. Attempting to bond the end of a 50-nm-diameter nanotube using an epoxy containing silver flake with dimensions of 20 x 20 microns is ineffective due to the difference in size of two orders of magnitude. It is difficult even to locate the nanotube in the gigantic matrix. Instead, a new class of conductive epoxy adhesives is required.

New Class of Adhesives for Nanotubes

Transene Co., Danvers, Mass., is now offering Nanopoxy 60, a high-bond-strength epoxy with silver flake below three microns in each dimension. Reducing the conductive flake size by an order of magnitude has been found to afford manageable, productive bonding for nanotubes. By developing this unique conductive-adhesive technology, Transene is creating a range of epoxies to meet the requirements of diverse handling, bonding and processing applications.As an example, the technology used to develop a two-part system such as Nanopoxy 60 is easily transferable to a one-part system with specific viscosity requirements, depending on the needs of the researcher or manufacturer. Transene currently offers a suite of conventional conductive epoxies that are drawn upon to create new nanoscale-ready adhesives.

Economics and consumer demands will continue to push electronic devices to smaller sizes until the term microelectronics is replaced by nanoelectronics. In order to support this broad change in manufacturing, suppliers of supporting materials such as electrically conductive adhesives must continually determine and meet the changing demands of the state of the art. By providing the means to research, measure and analyze nanomaterials, Transene is making an important contribution to the evolution the electronics technology.

Additional information on Nanopoxy conductive epoxy adhesives is available from Transene Co., Inc., 10 Electronics Ave., Danvers MA 01923; phone 978-777-7860; fax 978-739-5640; e-mail epoxy@transene.com; or visit the Web site www.transene.com. Or Circle No. 74.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!