An Alternate to Dispensing

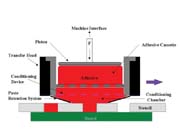

As a high-throughput alternative to serial adhesive dispensing, high-volume surface mount assembly facilities are using stencil printing platforms equipped with relatively thick, lightweight acrylic stencils and enclosed print heads to deposit large numbers of glue dots of varying heights in a single print cycle.

The enabling factor for adhesive printing is that aperture diameter controls deposit height. To produce glue dots with heights of 75mm to 1 mm, apertures of different sizes are machined into a single stencil. In a 1-mm-thick stencil, apertures of 0.6, 0.8 and 1.0 mm in diameter produce dots for small 0603, 0805 and 1206 components. For larger components, two to three apertures of 1.5 to 2 mm diameter each produce dots for SOICs, and five apertures of 2 mm diameter each produce dots for QFPs.

When glue is deposited onto a stencil that has protruding leads from components previously placed on its underside, a 3-mm-thick stencil with clearance pockets routed into its underside, as well as different-sized apertures, is used. The pockets may be rectangular, circular or channel-like in shape and require 0.2 to 0.24 mm of clearance from fully drilled holes. To reduce the length of the narrow section of smaller holes (typically those that are less than 1 mm in diameter), the top of the aperture may be counterbored.

Stencils for adhesive deposition may be generated using Gerber, HPGL, DXF and ODB++ data, or designs can be scanned directly from a PCB. With CAD/CAM processing, manufacture can be completed in a few hours and, in many regions, stencils can be shipped to users by way of overnight delivery services.

Depositing the adhesive through the stencil may be done with a traditional squeegee; however, process control is optimized when an enclosed print head system is used. The enclosed print head, with its direct imaging system, encases the adhesive within an air-tight cassette, isolating it from the atmosphere. An air piston applies constant, pre-set pressure to deposit the material independently of print speed, ensuring rapid, consistent application of any number of glue dots in a typical eight-second print cycle.

For more information on stencil printing, contact DEK, e-mail mohanlon@dek.com or visit http://www.dek.com .

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!