Assembly EndUser: Using Design of Experiments to Trim Plastic Bonding Times

To learn if assembly throughput times could be shortened, researchers recently conducted a series of design of experiments (DOE) studies at a cell phone design and prototype manufacturing facility. In this DOE, experimenters analyzed a cell phone's design, in which a clear viewing lens, treated with pressure-sensitive adhesive (PSA), was machine-pressed into the back of a housing. Restraining pins and the PSA are designed to keep the lens in place during repeated drop tests.

The existing assembly procedure called for 30 psi to be applied for nine seconds to affix the lens to its housing. The DOEs were designed to learn whether the nine-second pressure time could be reduced to achieve the following improvements.

- Increased throughput

- Reduced cycle time

- Increased profit

Screening Experiment

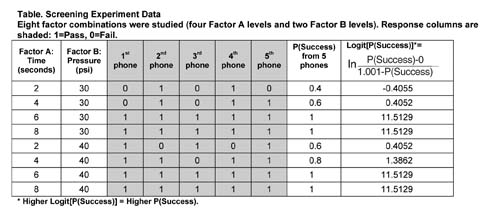

Researchers first created a two-factor, general-factorial DOE - one factor being pressure (pounds per square inch, or psi), and the other being time (seconds) the pressure is applied. Three cell phone batches, each containing 40 phones, were available. The statistical team used the first batch of 40 phones to conduct a screening experiment to find any significant effects. The subsequent two batches of 40 cell phones were later used, after the significant effects were identified.

Within the DOE screening experiment, four bonding times (2, 4, 6 and 8 seconds [Factor A]) and two pressure settings (30 and 40 psi [Factor B]) were addressed. Because there were eight factor combinations (four ‘Factor A' levels, two ‘Factor B' levels) and 40 available phones, five phones were tested at each factor combination. All 40 were tested in random order by dropping each unit a designated number of times from a height of five feet, on all six sides of the phone. The six-side drop sequence was identical for all tests. If a lens dislodged on any drop, it was considered a failed unit. Responses were recorded as pass=1, fail=0 (see Table). The underlying response distribution was not normally distributed, so all responses were logic-transformed before the Analysis of Variance (ANOVA) was used to analyze the experiment. The table shows the screening experiment data, including factors, factor levels and actual

and transformed factor-combination responses. ANOVA was performed on the transformed responses using Design-Expert® software.

Sequential Experiment

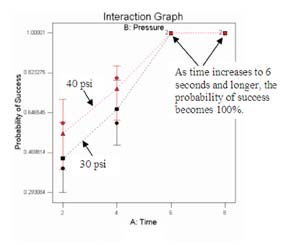

With the screening experiment, researchers learned that the amount of applied pressure (Factor B) was not statistically significant. By viewing the interaction graph (see Figure 1), they observed that Factor A (time), when set to six or eight seconds, increased the probability of passing the test (a secured lens), regardless of applied pressure.

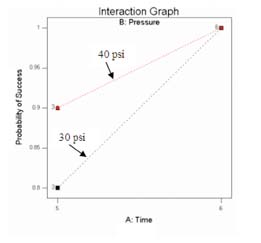

Using these screening experiment results, the statisticians designed a follow-up experiment by reducing times to five and six seconds, respectively, but keeping pressure to the two levels of 30 and 40 psi as before. Their objective was to determine if time could be reduced to five seconds while retaining quality. They used a randomized complete block design for the two-level factorial experiment. As before, Factor A was time and Factor B was pressure. Each block was represented by a batch of 40 phones. The phones were tested as before and the responses recorded. Each batch of 40 cell phones underwent testing at four factor combinations (two levels of A, two levels of B). Ten cell phones were tested at each factor combination. All 40 in each batch were tested in random order.

Recommendation

Investigating the interaction graph for the experiment in Figure 2, the researchers observed that pressure could be either 30 or 40 psi at six seconds. At five seconds, however, the required pressure was 40 psi, with the probability of passing the test being 90%.

The experimenters' recommendation was 30 psi for six seconds to guarantee that the phones satisfied the quality requirement. Based in part on this DOE, the prototype cell phone design was subsequently transferred to a high-production manufacturing facility. The findings have since increased the viewing-lens assembly speed by 33%.

For more information, contact Heidi Hansel, Stat-Ease Inc., 2021 E. Hennepin Ave., Suite 480, Minneapolis, MN, 55413; phone (612) 378-9449; e-mail heidi@statease.com; or visit http://www.statease.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!