Packaging EndUser: Tacktifier Talk

Case- and carton-sealing hot melts are formulated from polymer, wax, and tackifier. The tackifier is usually the largest component by weight and is what gives a hot-melt adhesive many of its unique performance attributes. With proper tackifier selection, a hot-melt adhesive can allow faster line speeds and fewer adhesive failures.

Terpene phenol tackifying resins have been referred to as a formulators' "secret weapon" because they can improve the application range and performance of a hot-melt adhesive. Next-generation terpene phenol resins are available with a significantly reduced odor profile. This improvement, coupled with inherent performance benefits, translates to a wider potential application range for this versatile tackifying resin.

Methodology

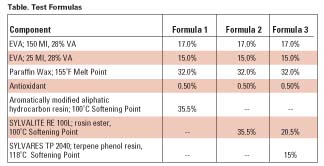

Three tackifier systems were tested to measure impact on hot tack and adhesion to recycled Kraft linerboard. Results showed that a rosin ester combined with terpene phenol significantly improved performance compared to an aromatically modified aliphatic hydrocarbon or a straight rosin ester (test formulas are shown in the table).

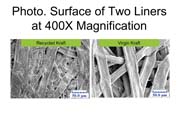

Each formulation was tested on recycled Kraft linerboard using an Olinger Bond Tester. The bond tester extrudes a hot-melt adhesive in the same manner as a case and carton sealer, controls the open and compression times, and then measures the force required to separate the substrates. Compared to virgin fiber, recycled Kraft is a more difficult surface to bond because the fibers are shorter and more densely packed (see Photo). On virgin Kraft substrate, the adhesive can more readily flow into the spaces between the fibers, forming a mechanical bond with the substrate. On recycled Kraft substrate, the

adhesive cannot penetrate the fibers and, therefore, must have a greater affinity for the surface to form a strong bond.

Fewer Adhesive Failures

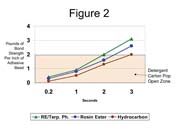

Board stock is often sourced from multiple suppliers, and typically varies in recycled content and its affinity for the adhesive. The higher surface affinity of terpene phenol resin means that the adhesive will perform over a wider range of substrate variations. Adhesives made with terpene phenol resin have significantly higher adhesive bond strength on recycled Kraft than the other formulas (see Figure 2). This higher bond strength makes adhesive placement and volume less critical, meaning that equipment is set up faster and adhesive usage could be reduced. A more robust adhesive is less likely to fail when cartons are packed and shipped. Thus, better bonds on recycled linerboard means less adhesive failure risk for packaging end users.

Faster Line Speeds

The adhesive strength of a hot melt before it has set is called hot tack. Adhesives with higher hot tack can hold a carton shut with less compression time and pressure, making variations in application conditions easier to tolerate. Cartons containing fragile items cannot sustain a lot of compression force; thus an adhesive with good hot tack will hold the inner and outer flaps closed while the adhesive sets.

High hot tack means the adhesive can perform at faster line speeds. We measured the crease resistance of some typical detergent cartons and found that 2 lbs of bond strength per linear inch of adhesive bead is required to hold the cartons shut. The data in Figure 3 shows that the adhesive containing a terpene phenol resin developed the required bond strength after two seconds of compression, while the adhesive with a hydrocarbon resin required three seconds. This 33% reduction in compression time translates to the ability to seal an additional 100 cartons per minute on a typical packaging line.

Summary

Terpene phenol tackifiers can be used in conjunction with rosin esters to formulate robust, low-odor adhesives that perform over a range of substrates and operating conditions. The benefit to packaging adhesive end users is reduced risk of field failures, ease of equipment setup, more universal performance and faster line speeds. These benefits translate to value for adhesive end users because of less customer complaints and higher production rates.

For more information on terpene phenol tackifiers, visit Arizona Chemical at http://www.arizonachemical.com or e-mail azcadhesives@ipaper.com.

Author's Note: Adhesive formulations must be tested for suitability prior to commercial use.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!