ZYMET: Reworkable Underfill (9/22/09)

This company has introduced a new reworkable underfill

encapsulant designed to underfill package-on-package (POP)

assemblies.

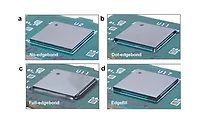

This company has introduced a new reworkable underfill encapsulant, CN-1728, designed to underfill package-on-package (POP) assemblies. Underfilled POPs have greater difficulty passing thermal cycle tests than underfilled BGAs. Compared to earlier generation underfills, CN-1728 has a lower coefficient of thermal expansion and higher Tg, and better compatibility with flux residues, both of which contribute to its superior thermal cycle performance.

CN-1728 is a fast-flowing capillary underfill with a viscosity of 900 cps, and it can be cured in as little as one minute at 150°C. These properties make the underfill particularly well suited for high-volume, high-speed in-line processing.

Rework is accomplished by use of elevated temperature, 170°C to 180°C, to remove the underfill fillet. Then, the BGA is lifted from the board after heating it to reflow temperature. Underfill residue is easily scraped off, again at 170°C to 180°C.

For more information, e-mail info@zymet.com.

This company has introduced a new reworkable underfill encapsulant, CN-1728, designed to underfill package-on-package (POP) assemblies. Underfilled POPs have greater difficulty passing thermal cycle tests than underfilled BGAs. Compared to earlier generation underfills, CN-1728 has a lower coefficient of thermal expansion and higher Tg, and better compatibility with flux residues, both of which contribute to its superior thermal cycle performance.

CN-1728 is a fast-flowing capillary underfill with a viscosity of 900 cps, and it can be cured in as little as one minute at 150°C. These properties make the underfill particularly well suited for high-volume, high-speed in-line processing.

Rework is accomplished by use of elevated temperature, 170°C to 180°C, to remove the underfill fillet. Then, the BGA is lifted from the board after heating it to reflow temperature. Underfill residue is easily scraped off, again at 170°C to 180°C.

For more information, e-mail info@zymet.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!